Preparation method of alkyl ketene dimer papermaking sizing agent and product

A technology of alkyl ketene dimer and sizing agent, which is applied in the field of papermaking, can solve the problems that the stability of emulsion droplet coalescence needs to be improved, and achieve the effects of low emulsification cost, improved hydrolysis resistance, and good sizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

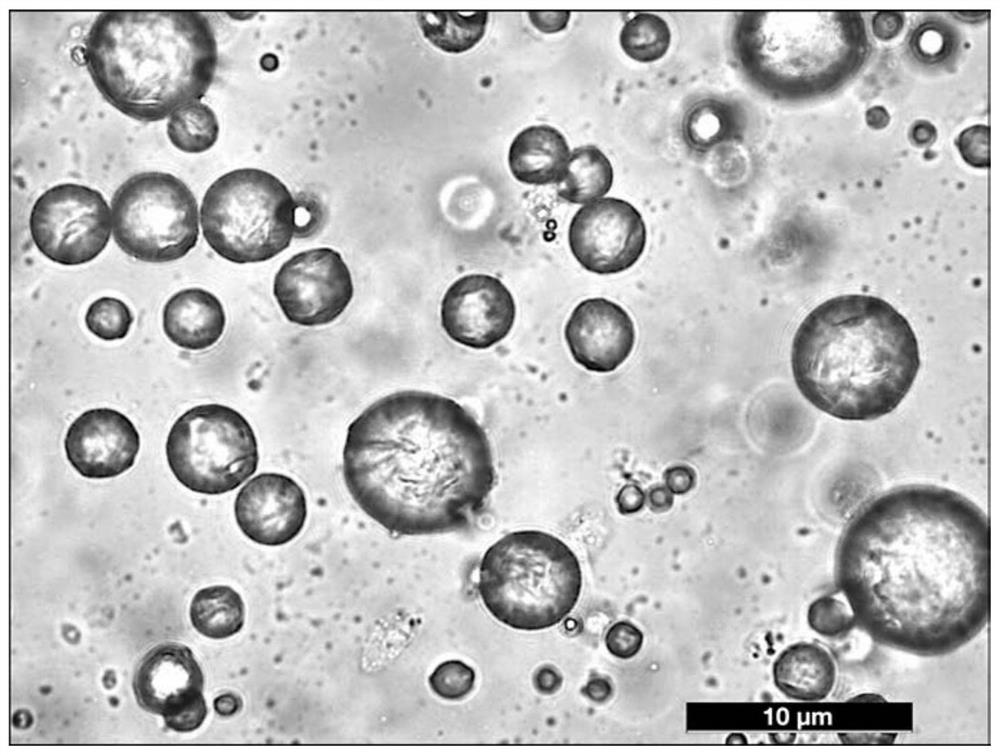

[0030] The preparation of embodiment 1 AKD sizing agent

[0031] (1) 1 part by weight of hectorite (average width of a single particle is 25nm, thickness 2nm) is dispersed in water to form a dispersion with a mass fraction of 0.05%, and 2 parts by weight of acetone, 10 parts by weight of ammonia monohydrate, 0.02 parts by weight of ten Mix hexaalkyltrimethylsiloxane, 500W ultrasonic dispersion at 25°C for 1 hour to obtain mixed solution I; add 0.05 parts by weight of tridecafluorooctyltriethoxysilane to mixed solution I, and continue ultrasonic dispersion for 1 hour , to obtain mixed solution II; the mixed solution II was vacuum-dried at 65° C. to obtain modified hectorite powder;

[0032] (2) Mix 1 part by weight of modified laponite powder with 20 parts by weight of perfluorohexane, disperse ultrasonically at 500W at 25°C for 1 hour, add 200 parts by weight of molten AKD and mix, continue ultrasonic emulsification at 85°C for 15 minutes, and cool To room temperature to obta...

Embodiment 2

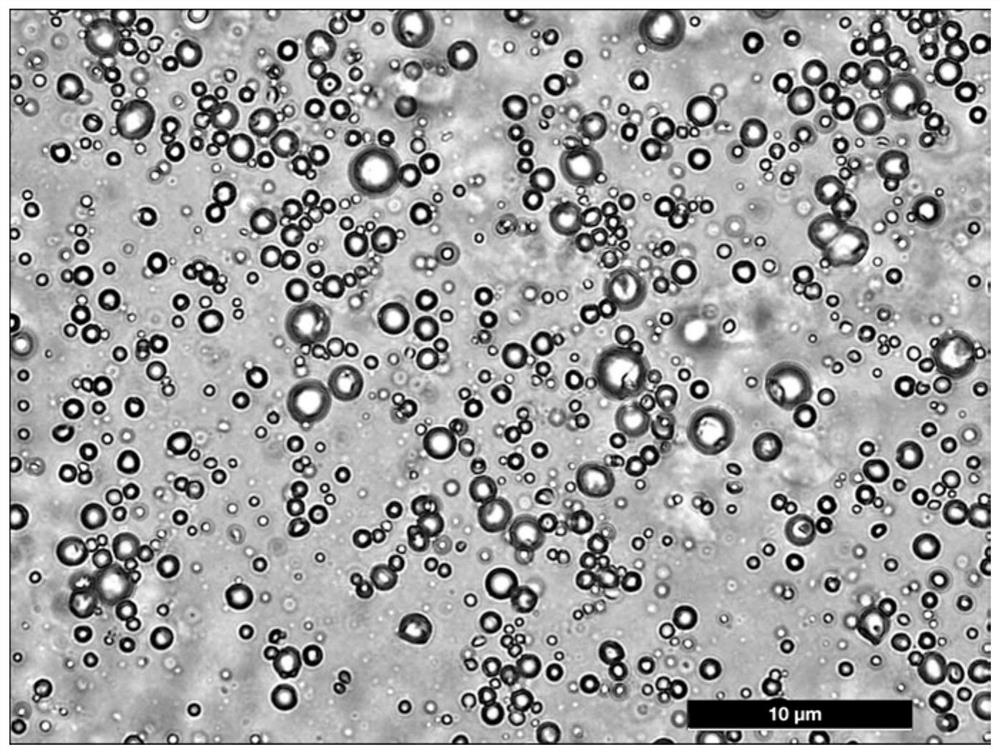

[0034] The preparation of embodiment 2 AKD sizing agent

[0035] (1) 1 part by weight of hectorite (average width of a single particle is 38nm, thickness 6nm) is dispersed in water to form a dispersion with a mass fraction of 1%, and 10 parts by weight of acetone, 20 parts by weight of ammonia monohydrate, 0.2 parts by weight of ten Mix hexaalkyltrimethylsiloxane and disperse with 1000W ultrasonic at 25°C for 1 hour to obtain mixed solution I; add 0.1 parts by weight of tridecafluorooctyltriethoxysilane to mixed solution I, and continue ultrasonically dispersing for 1 hour , to obtain mixed solution II; the mixed solution II was vacuum-dried at 65° C. to obtain modified hectorite powder;

[0036] (2) Mix 1 part by weight of modified laponite powder with 60 parts by weight of perfluorohexane, disperse ultrasonically at 1000W at 25°C for 1 hour, add 60 parts by weight of molten AKD and mix, and continue ultrasonic emulsification at 85°C for 15 minutes. Obtain AKD-A emulsion; It...

Embodiment 3

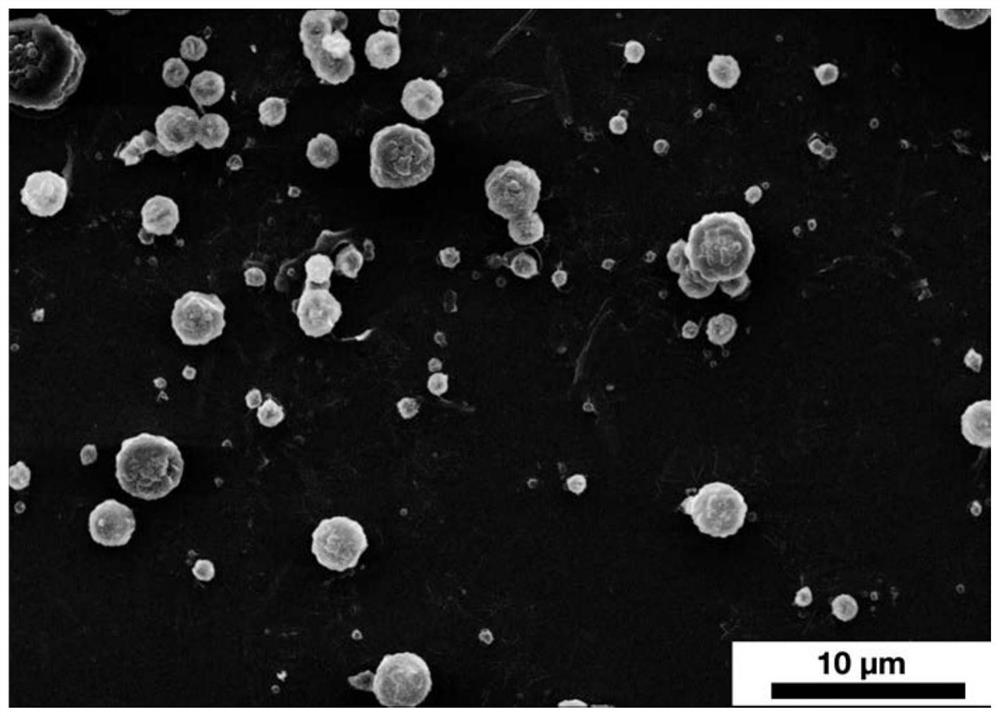

[0038] The preparation of embodiment 3 AKD sizing agent

[0039] (1) 2 parts by weight of hectorite (the average width of a single particle is 50nm, and the thickness is 10nm) is dispersed in water to form a dispersion with a mass fraction of 2%, and 1 part by weight of acetone, 2 parts by weight of ammonia monohydrate, 0.6 parts by weight of ten Mix hexaalkyltrimethylsiloxane and disperse it ultrasonically at 3000W for 1 hour at 25°C to obtain a mixed solution I; add 0.4 parts by weight of tridecafluorooctyltriethoxysilane to the mixed solution I, and continue ultrasonically dispersing for 1 hour , to obtain mixed solution II; the mixed solution II was vacuum-dried at 65° C. to obtain modified hectorite powder;

[0040] (2) Mix 1 part by weight of modified laponite powder with 100 parts by weight of perfluorohexane, ultrasonically disperse at 3000W for 1 hour at 25°C, add 10 parts by weight of molten AKD and mix, and continue ultrasonic emulsification for 15 minutes at 85°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com