Intelligent adjustment system and method for fully mechanized coal mining face

A fully mechanized mining face, intelligent adjustment technology, applied in the direction of earthwork drilling, slitting machinery, cutting machinery, etc. Problems such as unreasonable machine lap connection, etc., to achieve the effect of ensuring continuous and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

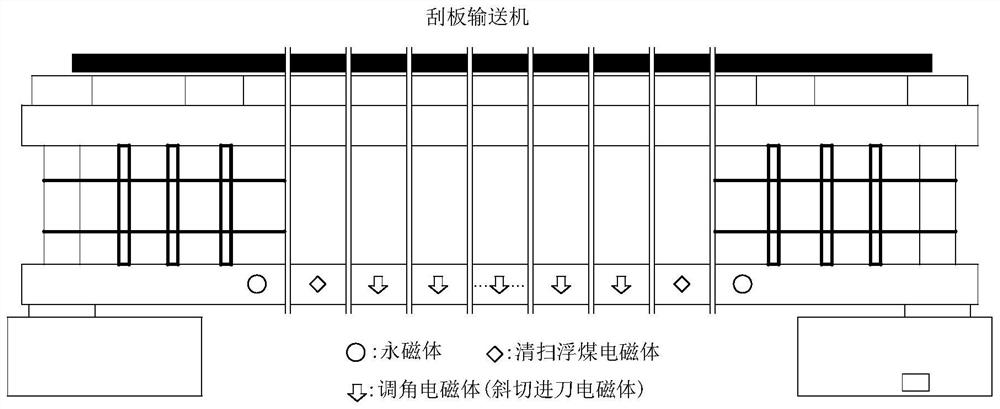

[0022] Please refer to figure 1 , an intelligent adjustment system for a fully mechanized mining face, comprising: a distance measuring sensor, set on the head of the scraper conveyor, for monitoring the length of the scraper conveyor head retracting or breaking out of the loader; a stroke encoder, set On the shearer, it is used to measure the running position of the shearer; permanent magnets are installed on the front side and the rear side of the scraper conveyor, and the shearer stroke encoder is reset to zero by the magnetic signal, which is used for Control the shearer's traction not to exceed the cutting range, the reversal of the upper and lower positions of the two drums, and the change of the direction of traction and cutting; the electromagnets for oblique cutting and feeding, one is installed on the head side and the tail side of the scraper conveyor; and , a plurality of angle-adjusting electromagnets, evenly distributed between the two bevel feed electromagnets; ...

Embodiment 2

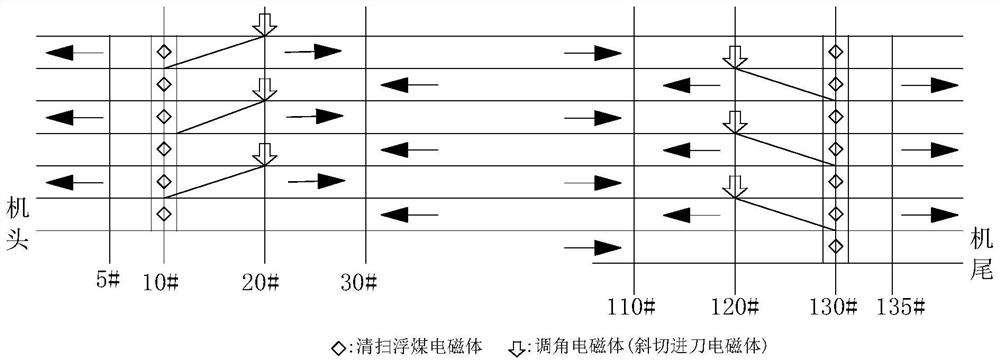

[0041] Please refer to figure 2 , a fully mechanized mining face adjustment method, comprising the following steps:

[0042] S1, the permanent magnet, the bevel feed electromagnet, the first angle adjustment electromagnet and the second angle adjustment electromagnet are sequentially arranged in a manner that the two ends of the fully mechanized mining face extend toward the middle thereof, wherein:

[0043] A second angle-adjusting electromagnet is distributed in the middle of the fully mechanized mining face, two permanent magnets are symmetrically distributed with respect to the second angle-adjusting electromagnet, two bevel feed electromagnets are symmetrically distributed about the second angle-adjusting electromagnet, and two The first angle-adjusting electromagnet is symmetrically distributed with respect to the second angle-adjusting electromagnet; the permanent magnet, the bevel feed electromagnet, the first angle-adjusting electromagnet and the second angle-adjusti...

Embodiment 3

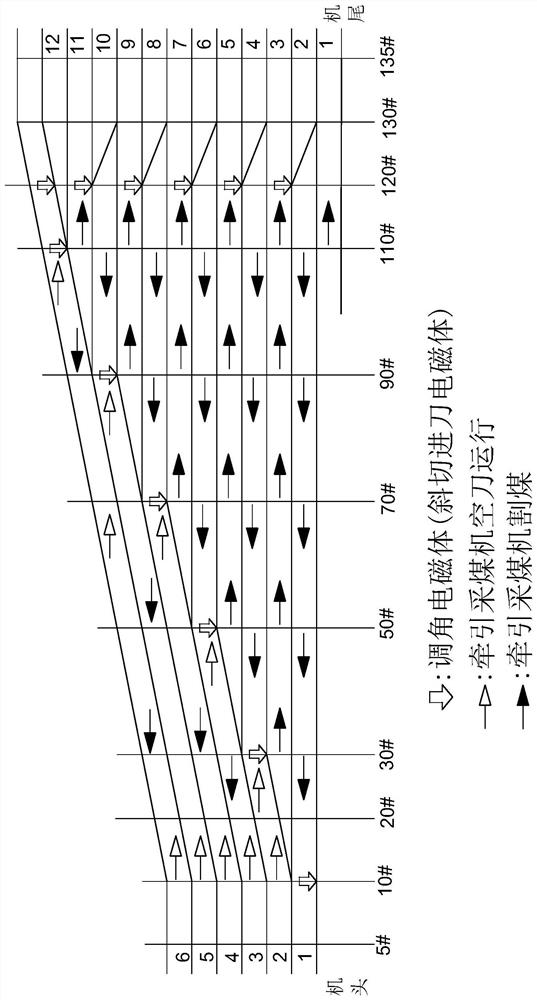

[0059] This embodiment is a production method of an irregular cycle of 2-pass machine tail: 1-pass machine head, and the duplicated content with Embodiment 2 will not be repeated here.

[0060] like image 3 As shown, set the width of the loader as L, the permanent magnet close to the loader is the head magnet, and the permanent magnet far from the loader is the tail magnet; when the length of the scraper conveyor head retracted into the loader is greater than or equal to L / 8 and less than L / 4, and when the shearer cuts from the tail of the scraper conveyor to the head of the scraper conveyor, S3 includes the following steps:

[0061] S31, after the shearer cuts through the tail end of the fully mechanized mining face, the tail magnet makes the stroke encoder return to zero, the shearer stops pulling, and the hydraulic support and the scraper conveyor follow the nose of the scraper conveyor. The way of extending to the tail of the machine is successively pushed to the coal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com