Wooden door line bending die

A technology for bending molds and lines, applied in wood bending, wood processing equipment, manufacturing tools, etc., can solve the problems of mold material waste, limited application range, etc., achieve optimized bending process, wide range of bending angles, and accelerated The effect of bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

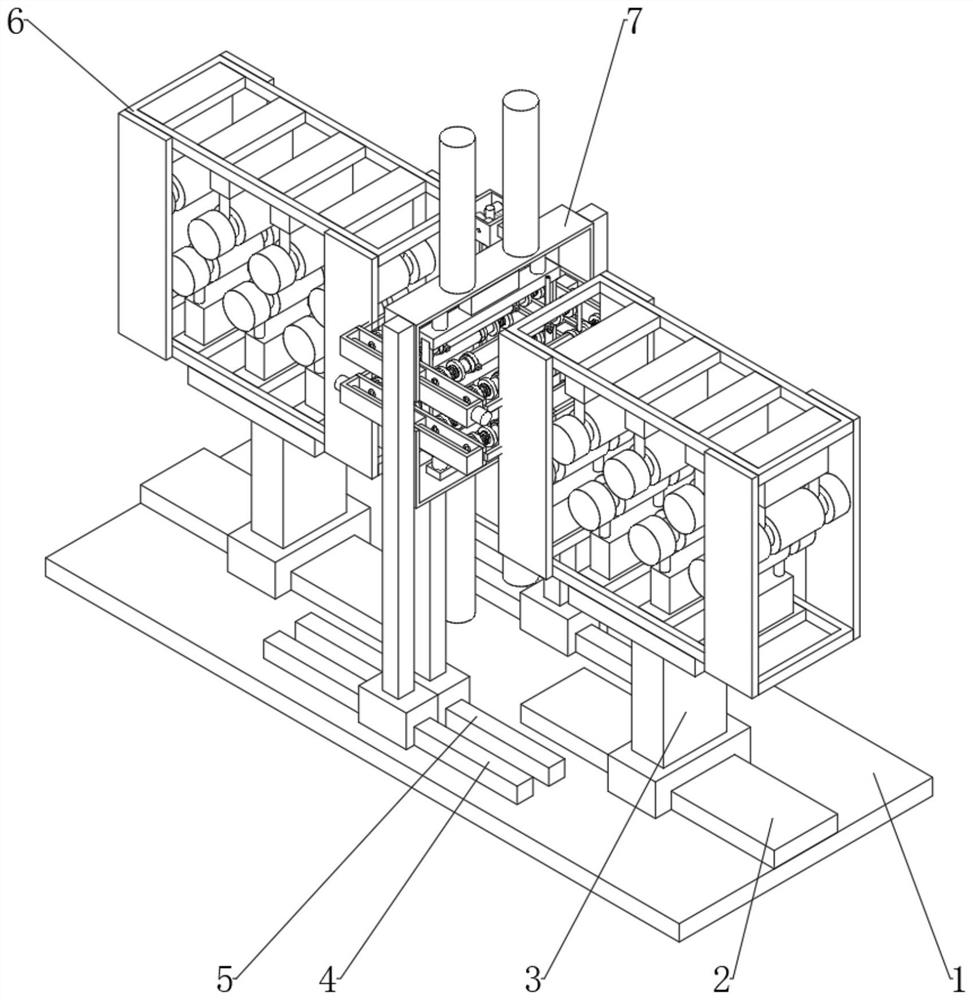

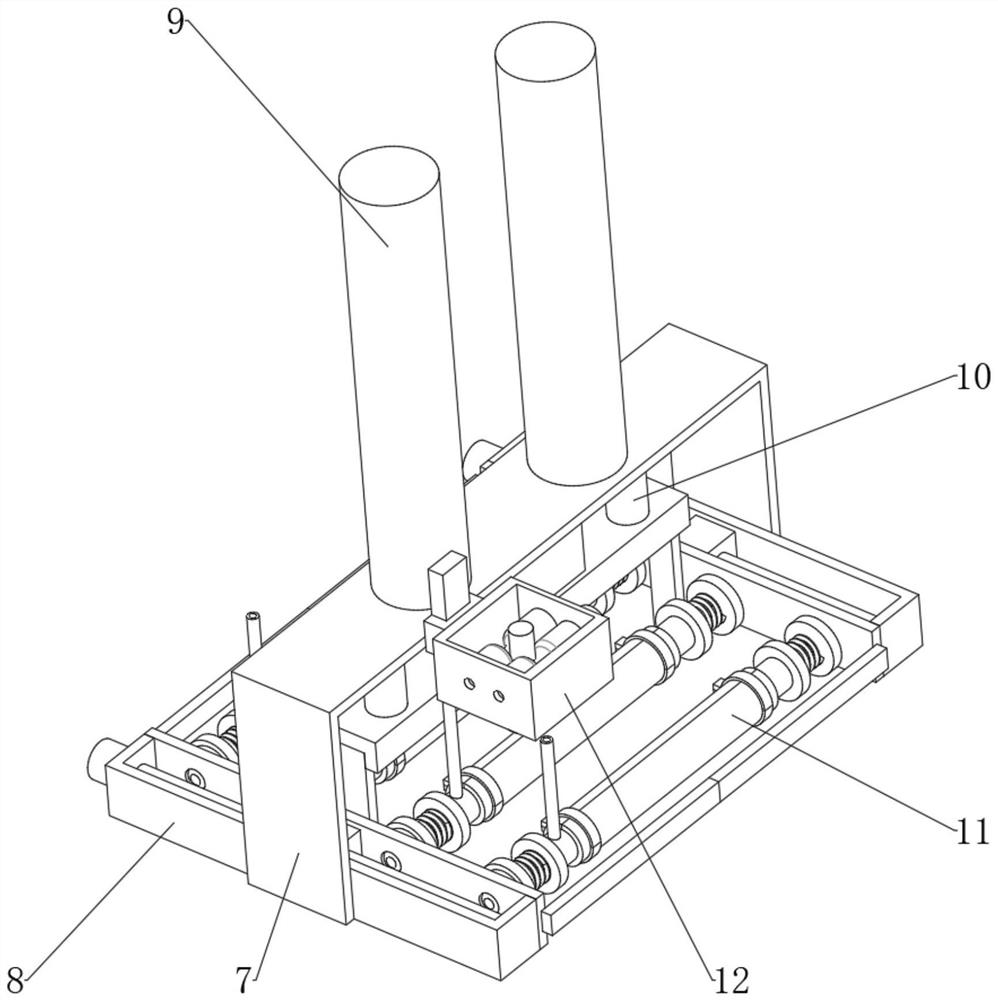

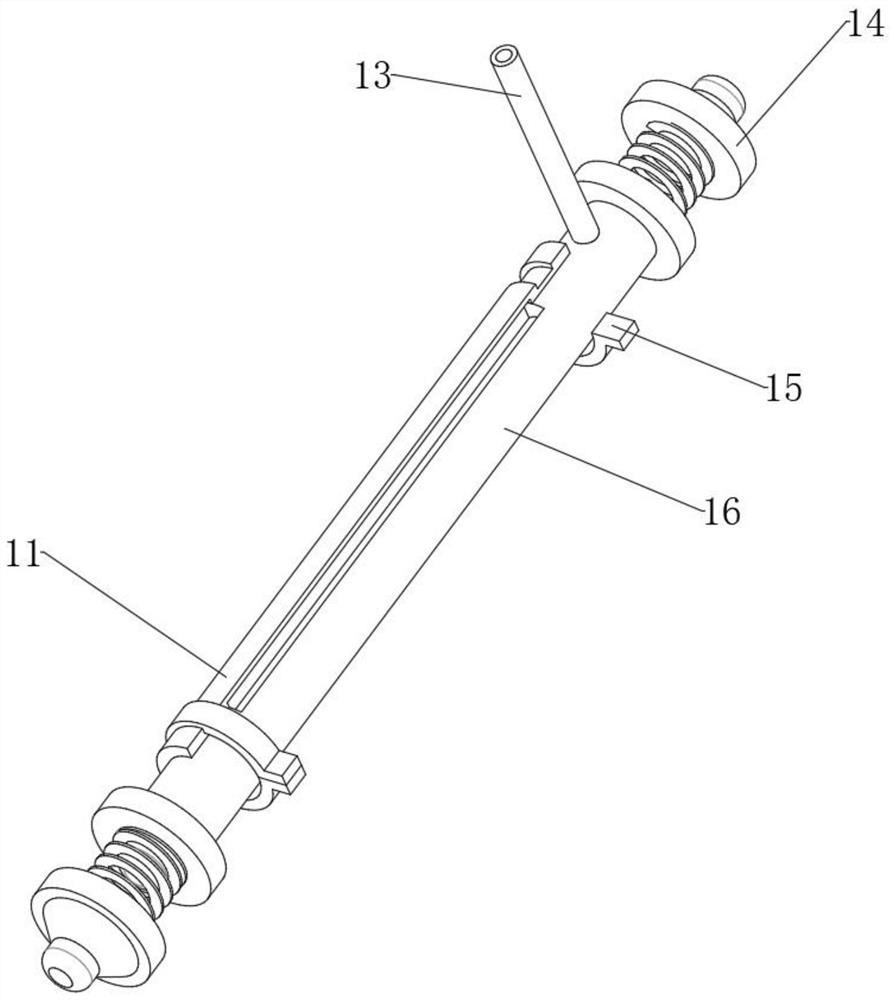

[0030] like Figure 1-Figure 8 As shown in the figure, the wooden door line bending mold provided in this embodiment includes a bottom plate 1 and an adjustment assembly arranged on the outer wall of the top thereof. There are two sets of symmetrical top bending assemblies directly above the adjustment assembly, and the top bending assembly includes two sliding frame plates 32 and the connecting plate arranged between them, the inner wall of the sliding frame plate 32 is provided with an insertion hole, the inner wall of the insertion hole is slidably connected with a plug 17, the outer wall of one end of the plug 17 is fixedly connected to the shrink plate 14, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com