Grabbing device for mechanical manufacturing

A grasping device and mechanical manufacturing technology, applied in the field of grasping devices for mechanical manufacturing, can solve the problems of poor flexibility between structures, poor coherence between structures, and inability to tightly fit and grasp accessories, and achieve installation and Easy to disassemble, reduce impact wear and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

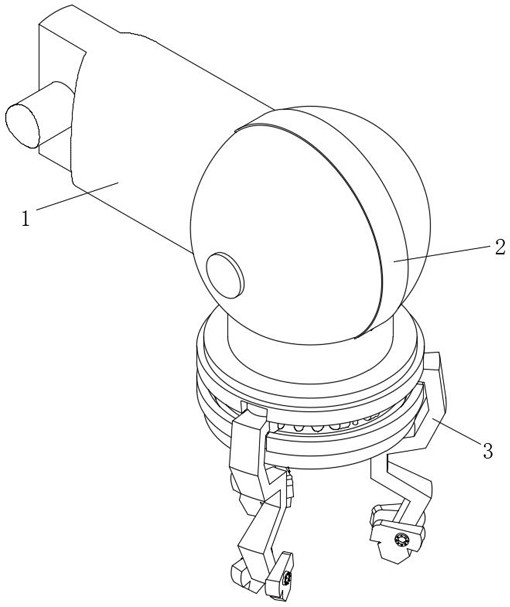

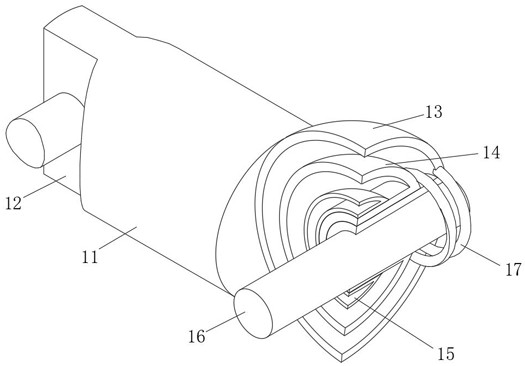

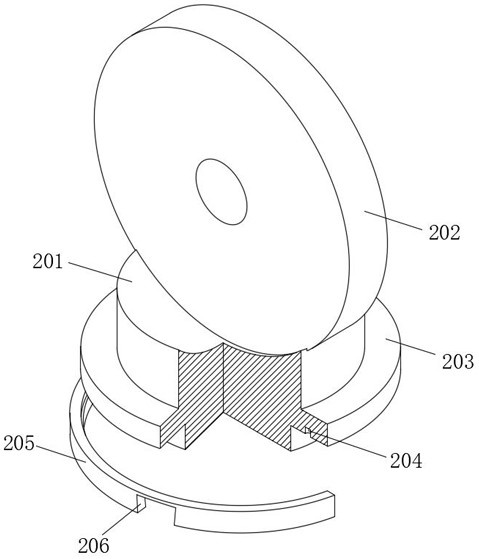

like Figure 1-Figure 6As shown, the present invention provides a technical solution: comprising an assembly mechanism 1, a hoisting assembly 2 is installed at the front end of the assembly mechanism 1, and a grabbing mechanism 3 is installed at the lower end of the hoisting assembly 2; the assembly mechanism 1 includes a short assembly rod 11, the short assembly rod 11 The rear end surface is provided with a clamping groove 12 for convenient assembly, the front end of the short assembly rod 11 is installed with an outer spherical shell 13, the inner side of the outer spherical shell 13 is installed with an air pressure cover 14, and the air pressure cover 14 is installed between the outer spherical shell 13 and the air pressure cover 14. There is a built-in spring 17, and the air pressure cover 14 is elastically installed with the outer spherical shell 13 through the built-in spring 17; the suction cup cover 15 is installed on the inner side of the air pressure cover 14, and th...

Embodiment 2

like Figure 5-Figure 6 As shown, the gripping mechanism 3 includes a hook 31, the upper surface of the hook 31 is fixedly connected with a connecting ball 32, the lower end of the hook 31 is fixedly connected with a bow plate 33, and the lower end of the bow plate 33 is installed with a side clamping block 34 The side clamp block 34 is installed with a positioning ring 35 on the side away from the bow plate 33, and the rear end surface of the positioning ring 35 is installed with a positioning insert 36 in a circular array, and the side clamp block 34 is fixed on one side of the bow plate 33. A shaft rod 37 is connected, an alignment hole 38 is opened on the surface of the bow plate 33, and the side clamp blocks 34 are symmetrically installed on the front and rear sides of the bow plate 33; The alignment hole 38 is combined and installed with the bow plate 33, wherein the side clamp block 34 is rotated and installed with the bow plate 33 through the shaft rod 37, and the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com