Split structure and cabinet easy to disassemble and wash

A technology that separates motors and racks, and is applied in the direction of electromechanical devices, casings/covers/supports, heating methods, etc., and can solve problems such as the inconvenience of dismantling motor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

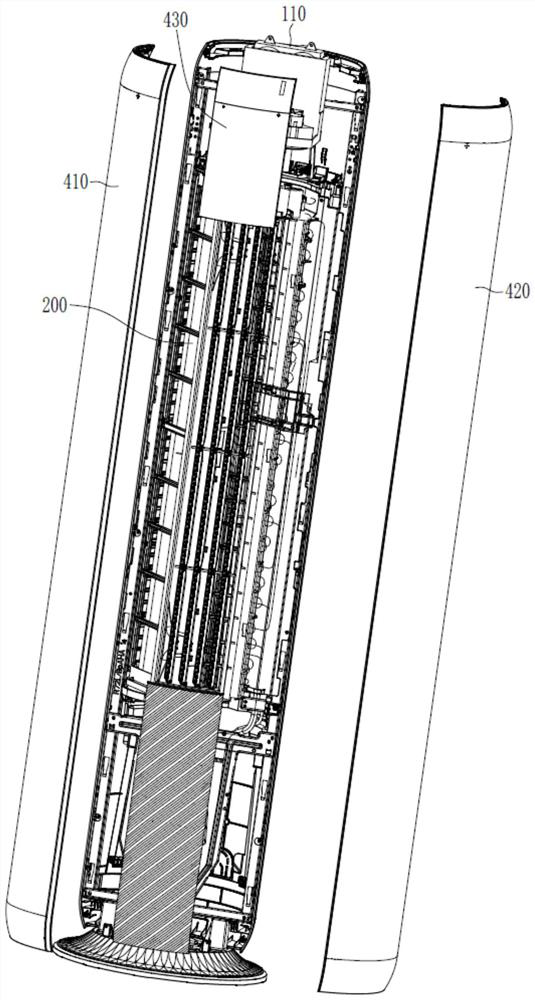

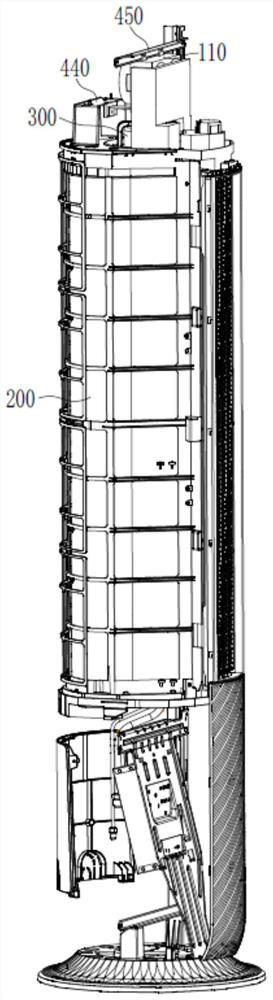

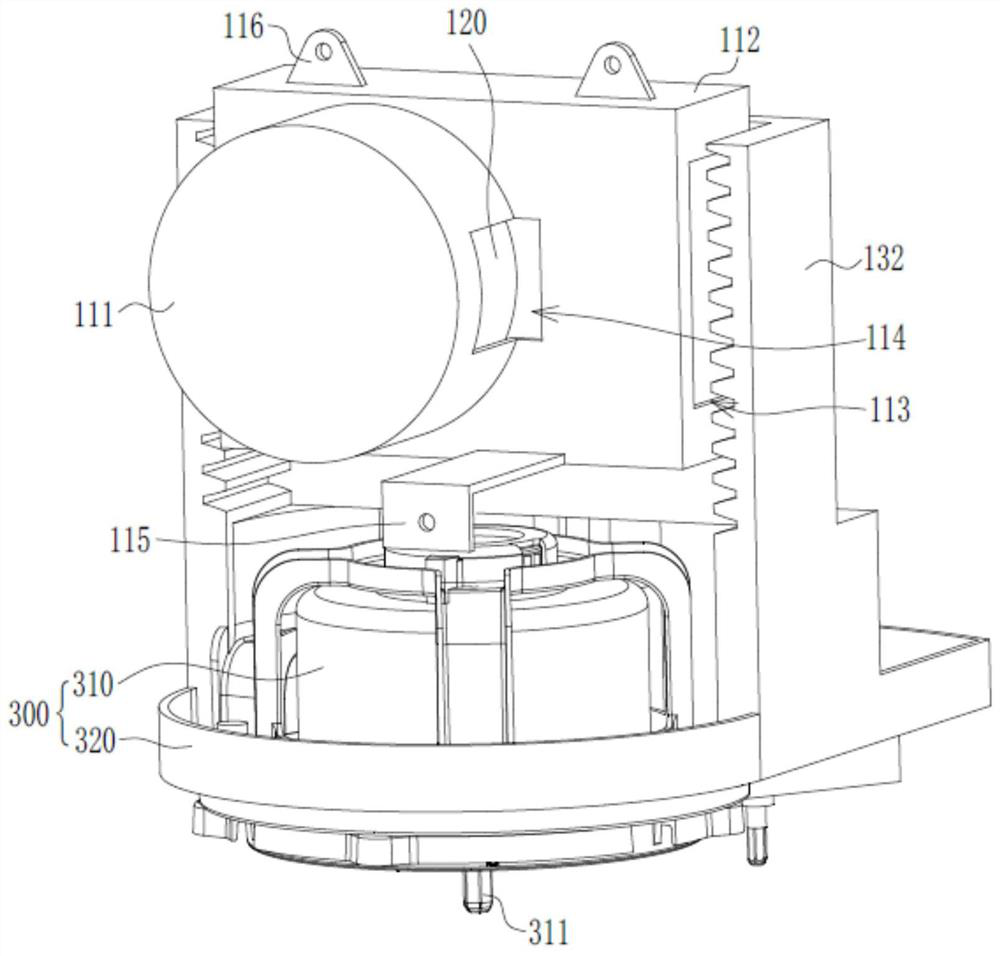

[0053] figure 1 It is one of the partial structural decomposition schematic diagrams of the easy-to-remove and wash cabinet machine provided in the first embodiment; figure 2 The second schematic diagram of partial structure decomposition of the easy-to-remove and wash cabinet machine provided in the first embodiment; Figure 5 It is a schematic structural diagram of the drive motor in the motor assembly of the easy-to-remove and wash cabinet machine provided in the first embodiment.

[0054] This embodiment provides an easy-to-remove and wash cabinet machine, such as figure 1 , figure 2 and Figure 5 As shown, it includes a frame, an air duct assembly 200 and a motor assembly 300 that are both arranged on the frame; the motor assembly 300 includes a bracket 320 and a drive motor 310 fixedly mounted on the bracket 320, the drive shaft 311 of the drive motor 310 and the air duct assembly The shaft hole transmission connection of 200 is used to drive the axial flow fan bla...

Embodiment 2

[0071] Image 6 A schematic diagram of the partial structure of the easy-to-remove and wash cabinet machine provided in the second embodiment; Figure 7 The disassembly structure of the easy-to-remove and wash cabinet machine and the structural schematic diagram of the motor assembly provided in the second embodiment.

[0072] like Image 6 and Figure 7 As shown, this embodiment also provides an easy-to-remove and wash cabinet machine, which is different from the easy-to-remove-wash cabinet machine provided in the first embodiment in that the split structure of the easy-to-remove and wash cabinet machine is the same as that provided in the first embodiment. The split structure of the easy-to-remove and wash cabinet machine is different, and the structure of the bracket 320 in the motor assembly 300 of the two is also different.

[0073] Specifically, as Image 6 and Figure 7 As shown, in the split structure provided in this embodiment, the accommodating box 110 only inc...

Embodiment 3

[0079] Figure 8 A schematic diagram of the partial structure of the easy-to-remove and wash cabinet machine provided in Embodiment 3; Figure 9 The disassembly structure of the easy-to-remove and wash cabinet machine and the structural schematic diagram of the motor assembly provided in the third embodiment.

[0080] like Figure 8 and Figure 9 As shown, this embodiment also provides an easy-to-remove and wash cabinet machine, which is different from the easy-to-remove and wash cabinet machines provided in the first and second embodiments in that the split structure 100 of the easy-to-remove and wash cabinet machine Excluding the accommodating box 110, the split motor 120 is directly installed on the frame, and the structure of the transmission mechanism is different.

[0081] Specifically, in the split structure 100 provided in this embodiment, the transmission mechanism includes a worm 151, a worm wheel 152, a first gear 153 and a first toothed belt 154, and the worm 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com