Liquid level monitoring device for SDS (Sodium Dodecyl Sulfate) stock solution supply barrel

A technology for liquid level monitoring and installation of grooves, applied in measuring devices, lubrication indicating devices, buoy liquid level indicators, etc., can solve the problems of high cost of hydraulic gauges, inability to know the original liquid of the original liquid cylinder in a timely and intuitive manner, etc. The effect of equipment usage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

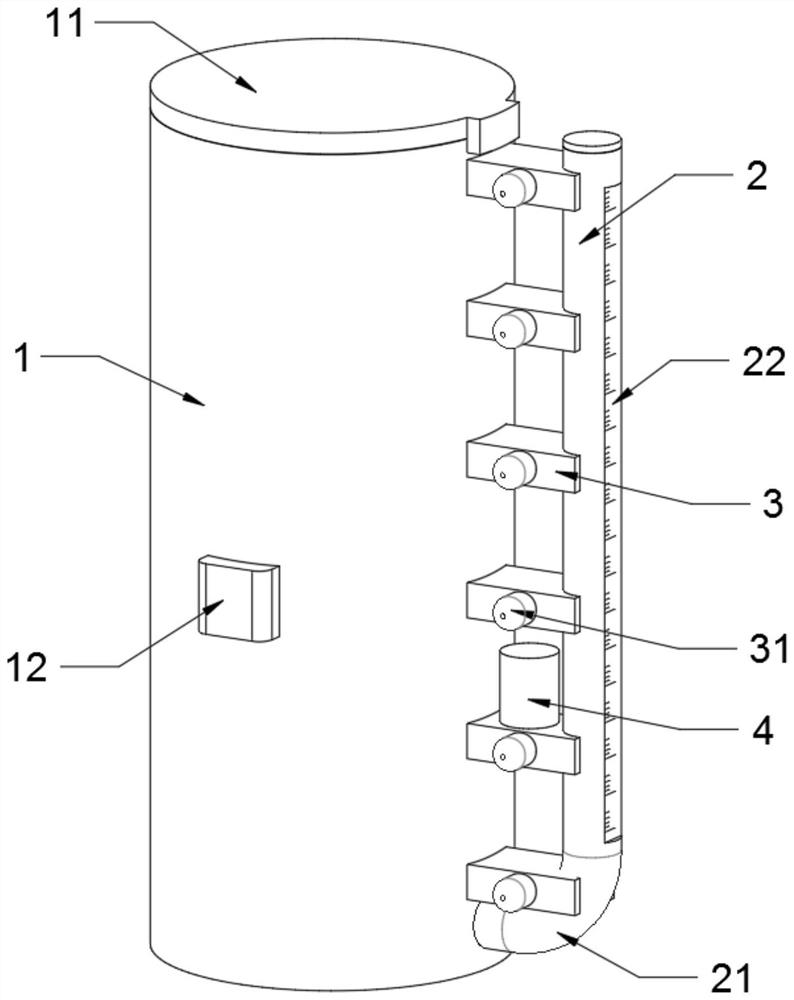

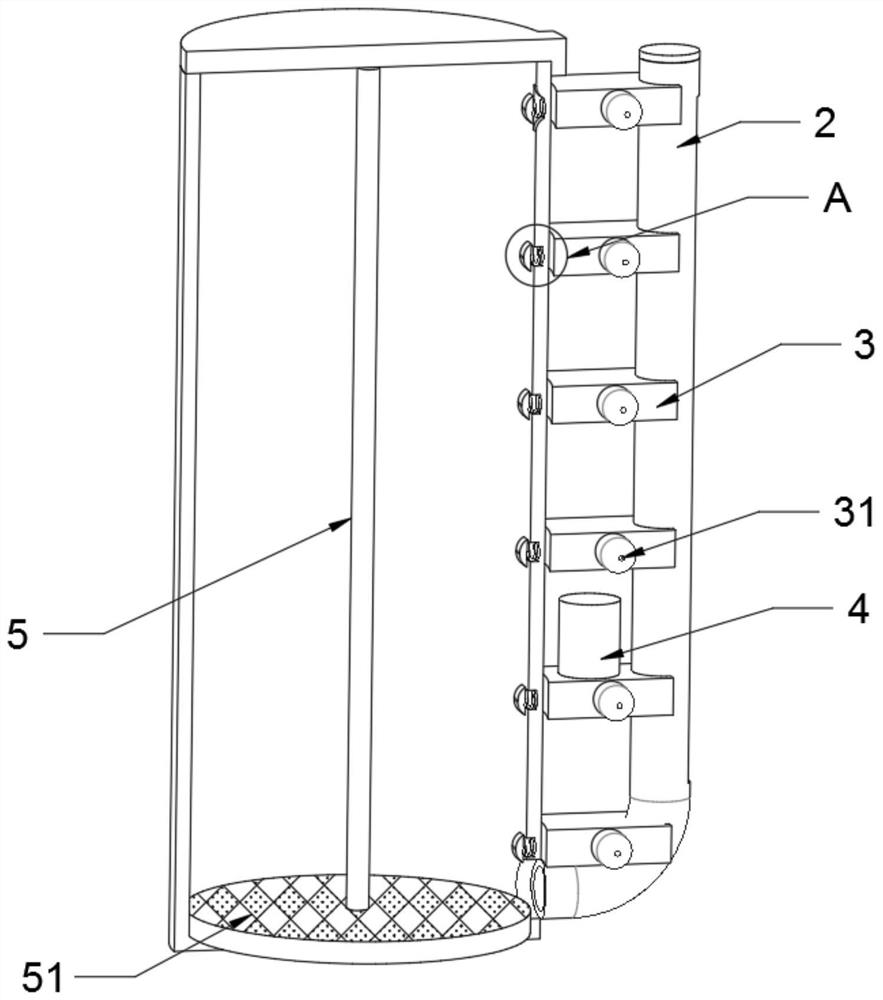

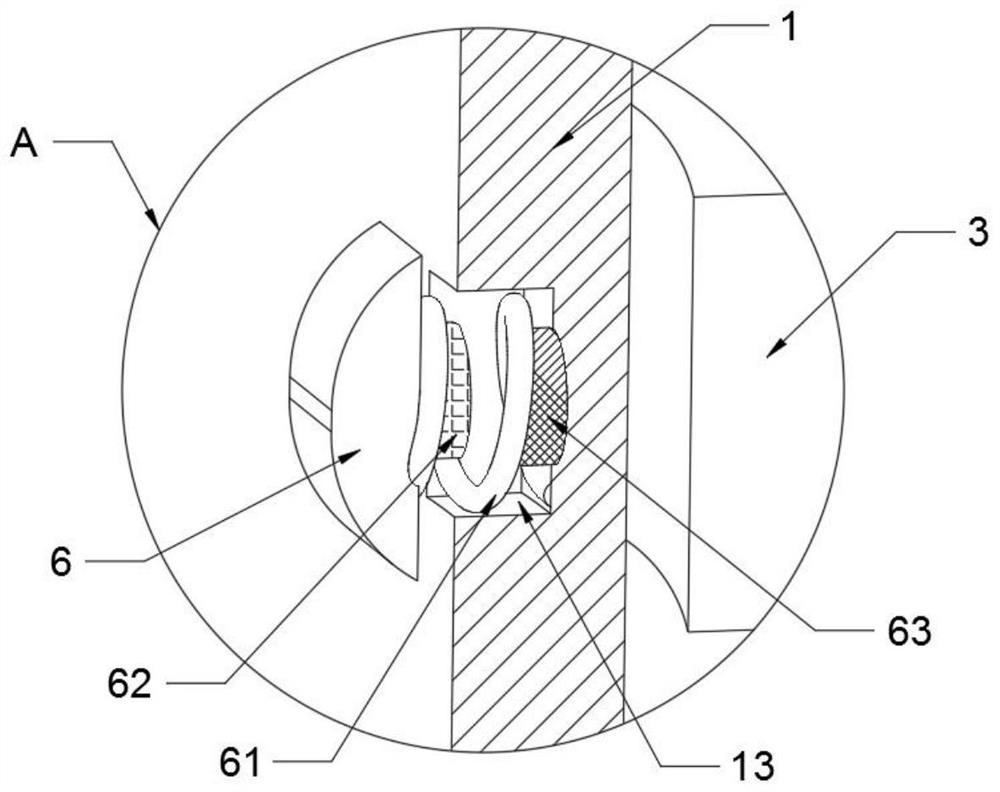

[0026] The embodiment of the present invention provides a liquid level monitoring device for an SDS raw liquid supply barrel, such as Figure 1-4 As shown, it includes a raw liquid cylinder 1, one side of the raw liquid cylinder 1 is provided with a communicating pipe 2, and the inner bottom of the communicating pipe 2 is provided with a connecting portion 21 bent to one side, and the communicating pipe 2 passes through The connection part 21 is fixedly connected with the raw liquid cylinder 1 and the communication pipe 2, the connecting part 21 and the interior of the raw liquid cylinder 1 are communicated and arranged;

[0027] The inside of the raw liquid cylinder 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com