Device and method for detecting tensile strength performance of packaging film

A detection device, tensile strength technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure test material strength, etc., can solve the problem of reducing the accuracy of sample placement, the convenience of sample placement, and affecting the progress of sample testing Efficiency, inability to fully observe the placement of samples, etc., to achieve the effects of good work stability, easy pressing, and improved linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below the attachment in the embodiments of the invention will be clearly and fully described in the technical solutions in the embodiments of the present invention. Obviously, the embodiments described are only a part of the embodiments of the invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by ordinary technical personnel in the art under the premise of not creating creative labor belong to the protection of the present invention.

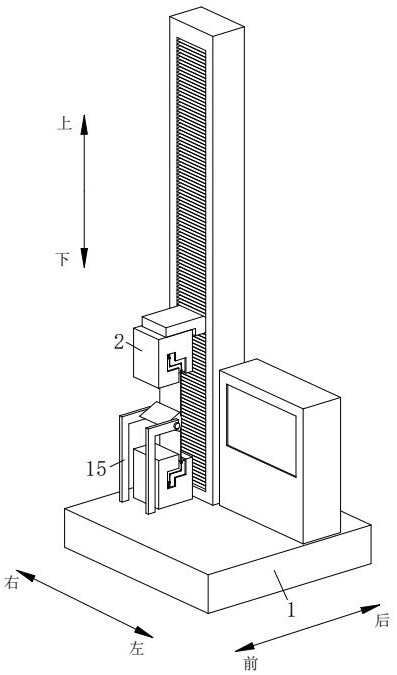

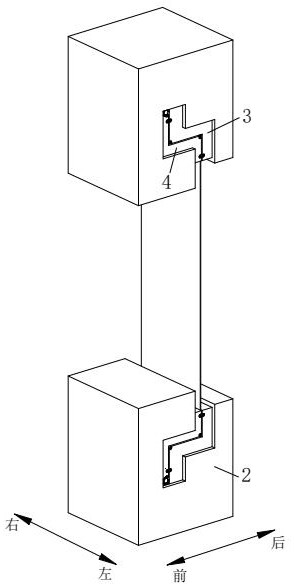

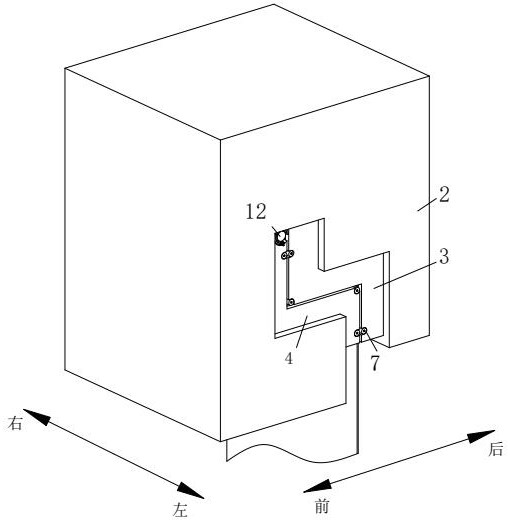

[0036] See figure 1 As well as figure 2 As well as image 3 As well as Figure 5 As well as Figure 8 and Figure 10 , A packaging film stretching strength performance detection device and detection method, including detection device body 1, detection device body 1 with a fixed -holding department with symmetrical symmetry, the clamping department includes the clamping part and auxiliary part, holding the holding held Part of the installation seat 2, the connection of the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com