Motor integrated motor protection device

A technology of motor protection and protective cover, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of affecting the protection effect of the protective cover on the integrated motor and the wear of the contact position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

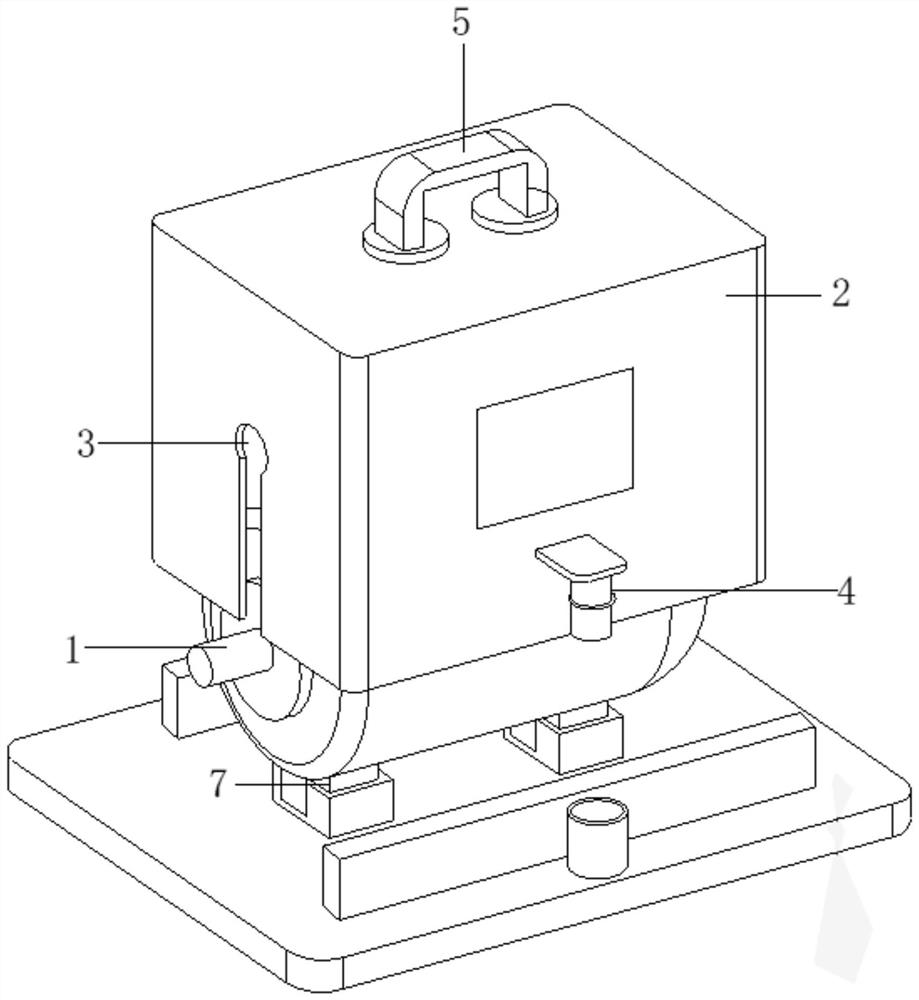

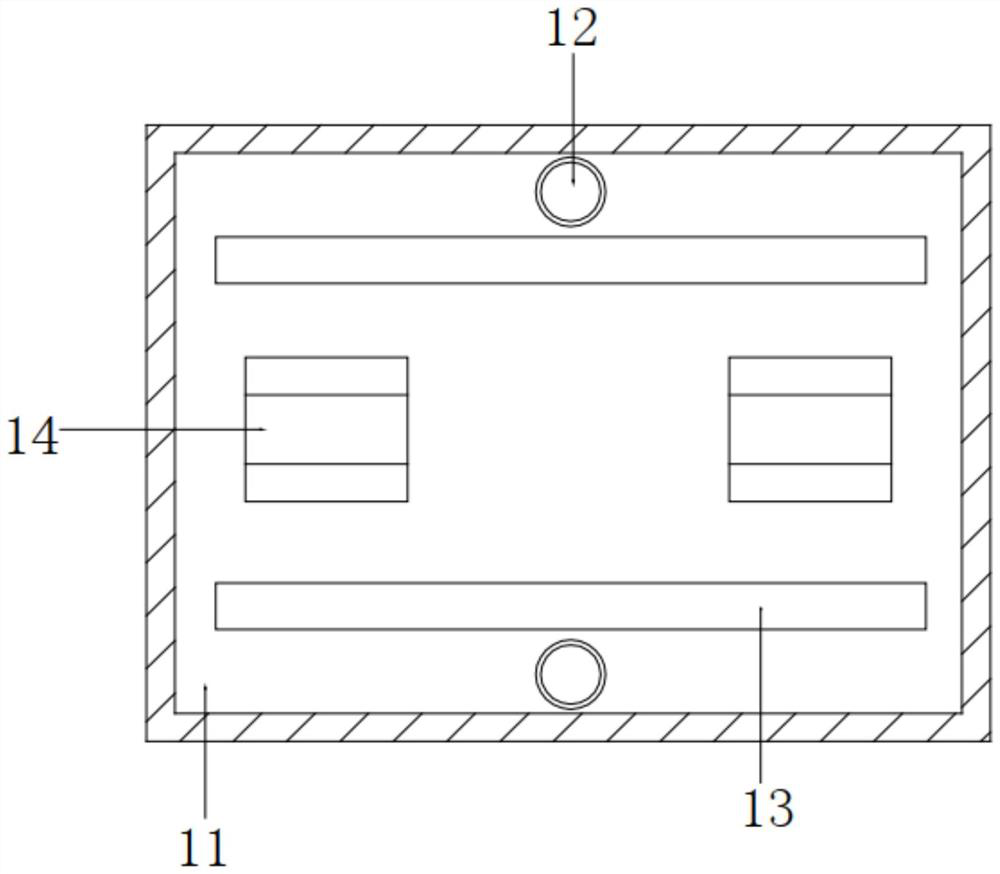

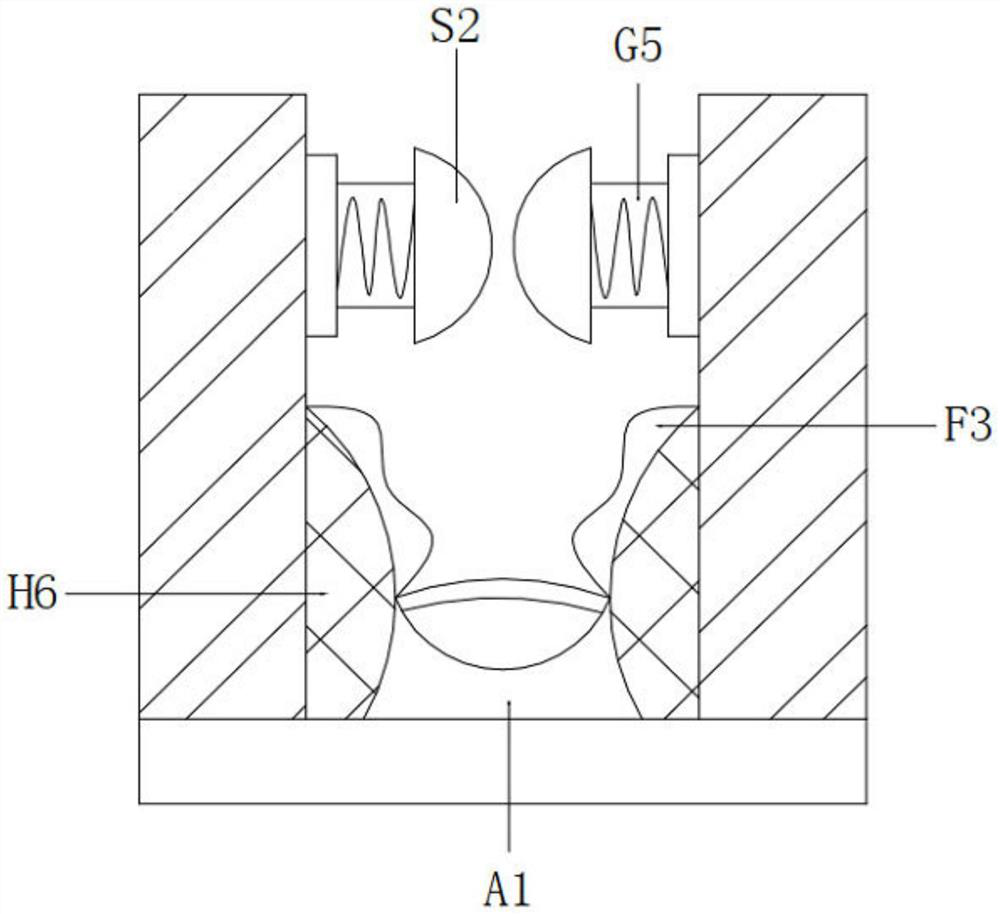

[0031] like Figure 1-2 As shown, this embodiment includes a base 11 , an integrated motor 1 disposed on the base 11 , and a protective cover 2 sleeved on the integrated motor 1 , wherein the bottom of the integrated motor 1 is provided with feet 7 , and the base 11 is There is a clamping assembly 14 that matches the support feet 7; both sides of the protective cover 2 are provided with plug connectors 4, and the base 11 is provided with a butt pipe 12 that matches the plug connectors 4; and the base 11 is also provided with The protective cover 2 has a matching limit card track 13 at the bottom; both ends of the protective cover 2 are provided with a docking slideway 3 that matches the output shaft of the integrated motor 1; and the top of the protective cover 2 is provided with a handle 5, Therefore, after the clamping assembly 14 is fixedly connected with the support feet 7, the integrated motor 1 can be stably installed on the base 11, and then the protective cover 2 is ve...

Embodiment 2

[0037] like Figure 1-2 As shown, this embodiment includes a base 11 , an integrated motor 1 disposed on the base 11 , and a protective cover 2 sleeved on the integrated motor 1 , wherein the bottom of the integrated motor 1 is provided with feet 7 , and the base 11 is There is a clamping assembly 14 that matches the support feet 7; both sides of the protective cover 2 are provided with plug connectors 4, and the base 11 is provided with a butt pipe 12 that matches the plug connectors 4; and the base 11 is also provided with The protective cover 2 has a matching limit card track 13 at the bottom; both ends of the protective cover 2 are provided with a docking slideway 3 that matches the output shaft of the integrated motor 1; and the top of the protective cover 2 is provided with a handle 5, Therefore, after the clamping assembly 14 is fixedly connected with the support feet 7, the integrated motor 1 can be stably installed on the base 11, and then the protective cover 2 is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com