Processing system

A technology for processing systems and sliding parts, which is applied in the direction of program-controlled manipulators, chucks, manipulators, etc., can solve the problem of large assembly space and achieve the effects of small assembly space, easy maintenance, and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

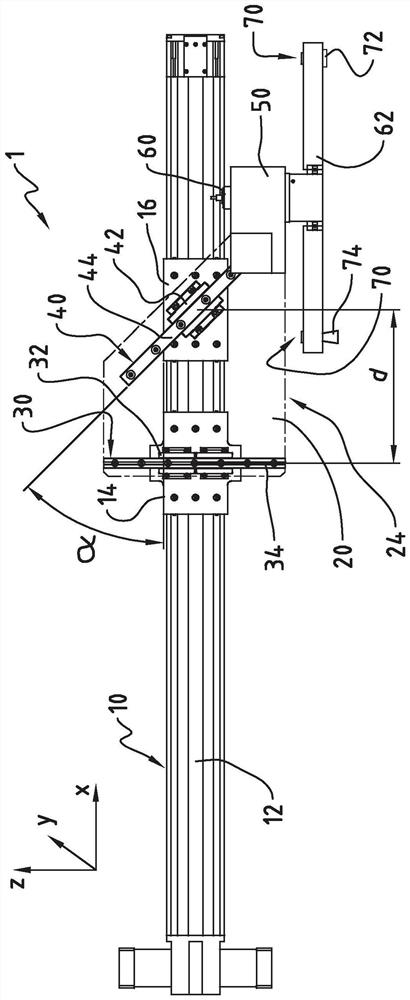

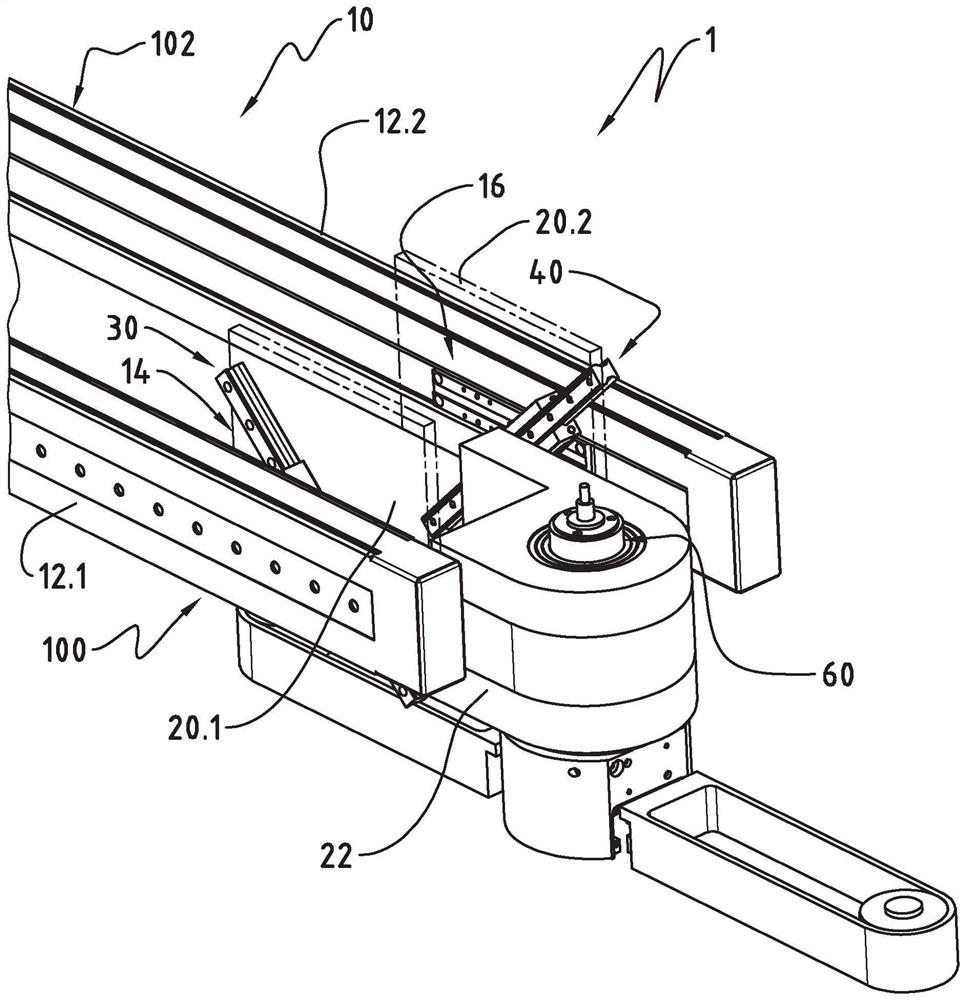

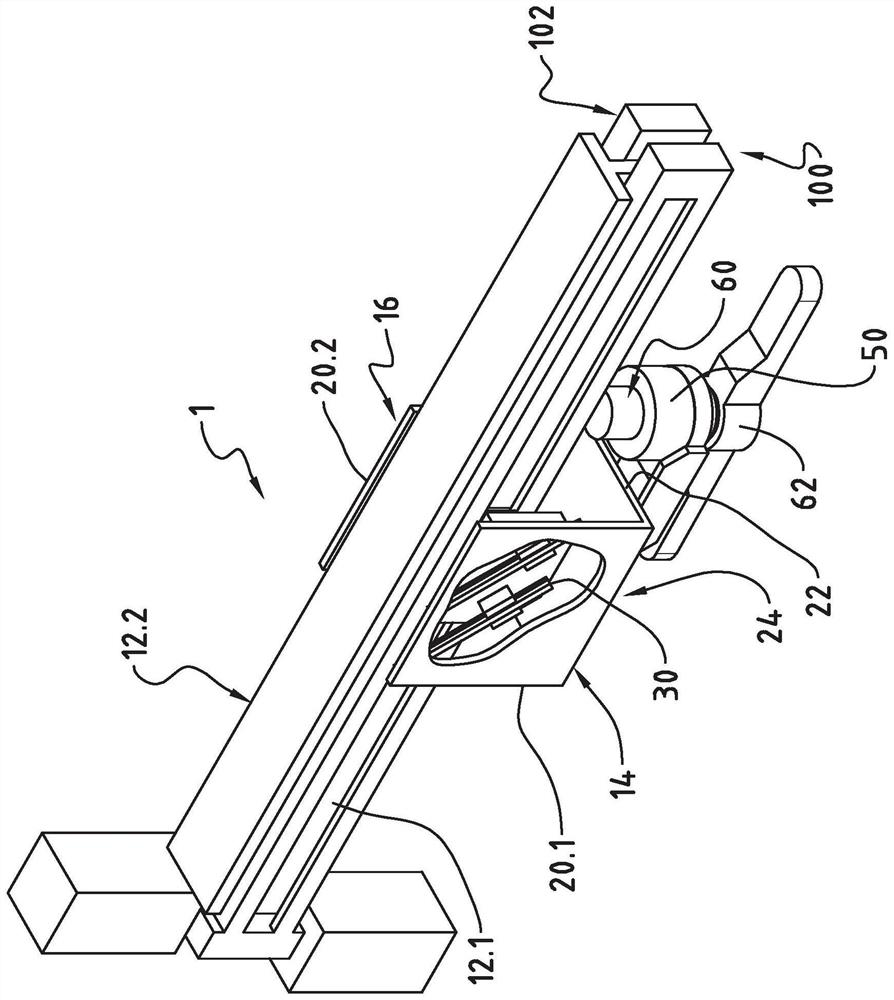

[0039] figure 1 The processing system 1 shown in is associated with an apparatus, preferably a pressing apparatus or a powder press accordingly, for producing moulded parts from powdered and / or granular compressible materials using upper and lower punch arrangements. The processing system 1 comprises a control unit (not shown), which may also have a powder press. exist figure 1 In a first embodiment of the invention, a linear axis system can be controlled by means of a control unit, which comprises: a linear axis 10, which is designed as an X linear axis 10; and, a linear guide 12 extending in the X direction, which is A first guide slide 14 and a second guide slide 16 are arranged thereon. The first guide slide 14 and the second guide slide 16 can be driven along the linear guide 12, the first guide slide 14 and the second guide slide 16 being controlled independently of each other by the control unit. Thus, the first guide slide 14 and the second guide slide 16 can be mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com