Thermoplastic composite board as well as preparation method and product thereof

A composite sheet, thermoplastic technology, applied in the field of composite material manufacturing, can solve the problem of undisclosed partial reinforcement of luggage, etc., to achieve good balance, impact resistance and/or static load capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

I: Preparation of thermoplastic composite sheets

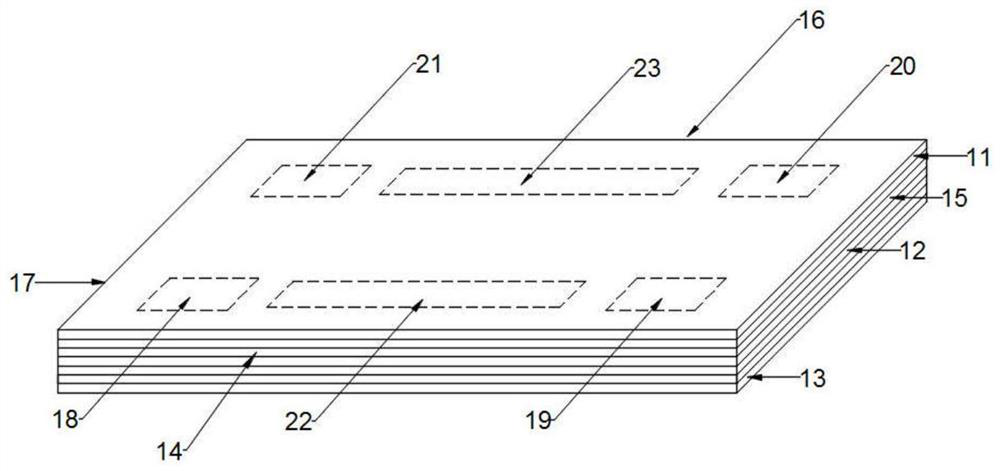

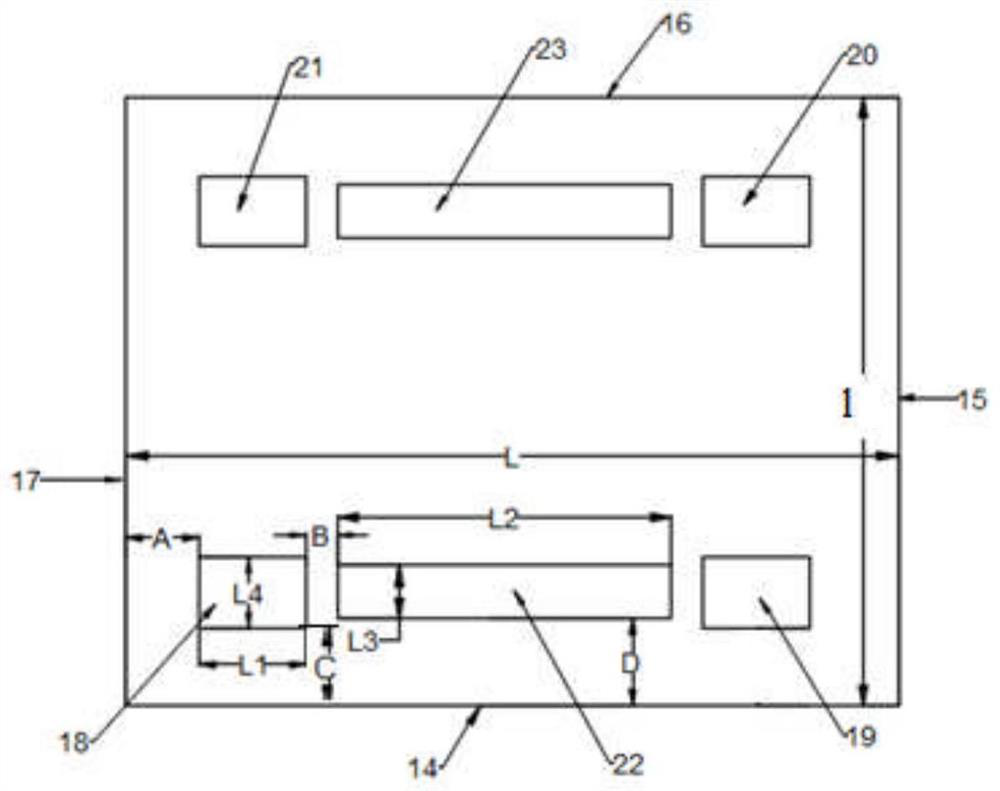

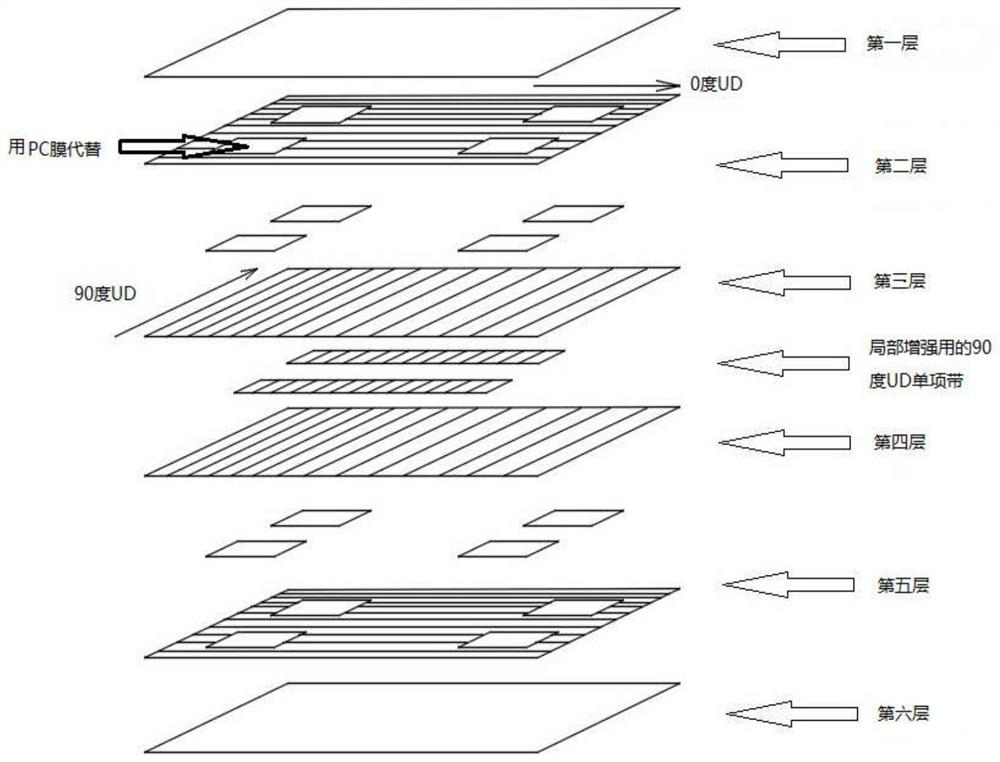

refer to image 3 , the thermoplastic composite sheet to be prepared presents an up-down symmetrical structure and consists of the following layers:

The first layer (upper surface layer) is PC film with a size of 650mm×750mm;

The second layer (intermediate layer) is a 0 degree carbon fiber reinforced polycarbonate unidirectional tape with four first localized reinforcement areas by cutting out the 0 degree carbon fiber reinforced polycarbonate unidirectional tape in the four areas The tape is then formed by replacing the excised area with a PC film, the size of the first local enhancement area is 90mm × 78mm, the distance to the side in the 0-degree direction approaching is 32.5mm, and the distance to the side in the 90-degree direction approaching is 30mm;

The third layer (middle layer) is a 90 degree carbon fiber reinforced polycarbonate unidirectional tape;

The fourth layer (middle layer) is the same as the third lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com