Shape-forming film, and optical laminate provided with shape-forming film

A technology of optical laminates and films, applied in optics, optical elements, filters, etc., to achieve the effect of excellent brightness, brightness field of view, and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

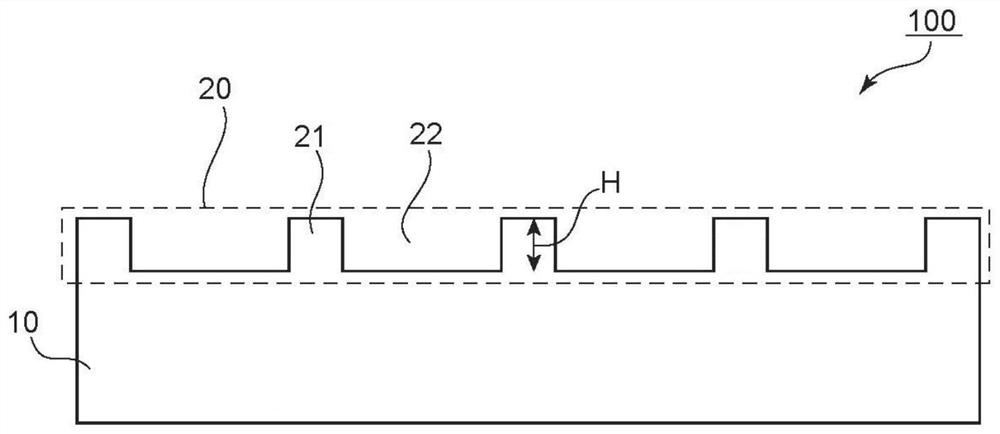

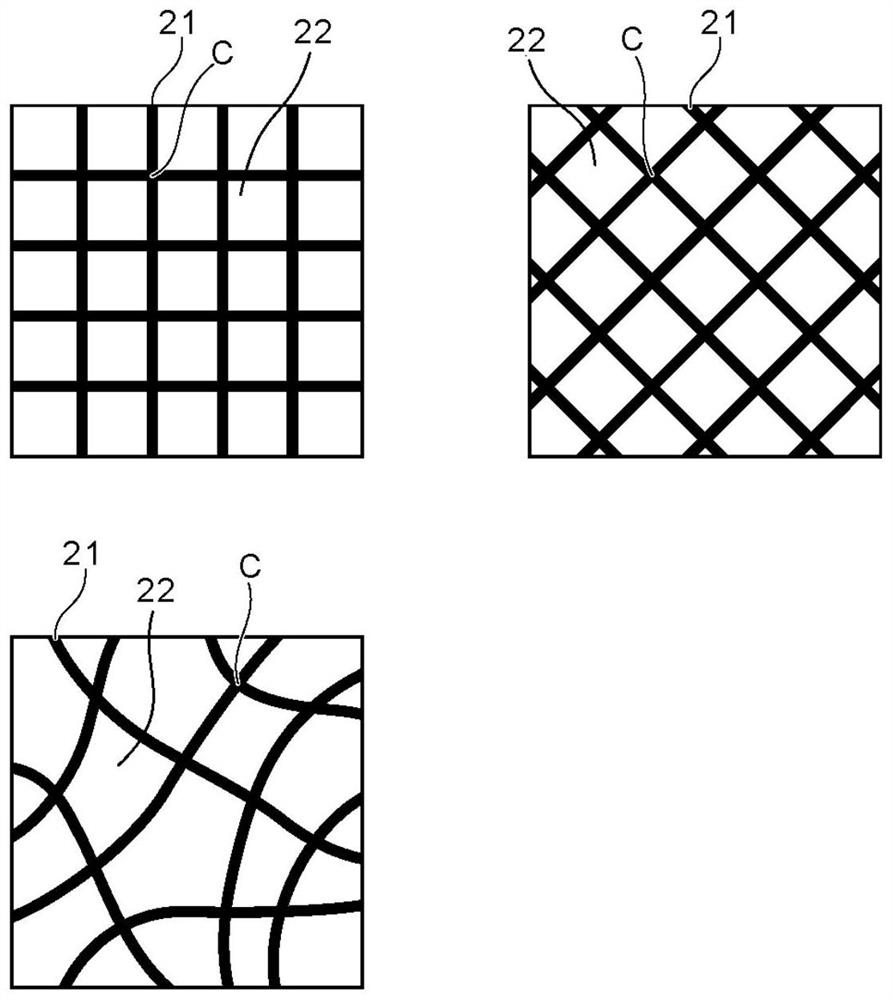

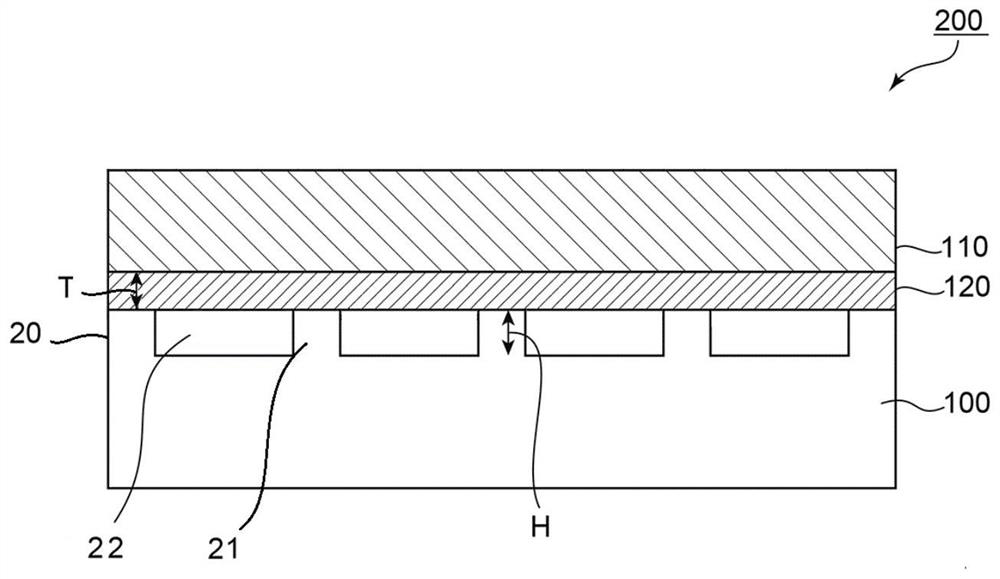

[0123] A methacrylic resin (manufactured by Kuraray Co., Ltd., product name "PARAPET HR-S") was put into a single-screw extruder and melt-extruded at 260°C while giving a concavo-convex shape to one surface with an embossing roll, A shaped film was obtained (thickness: 50 μm, convex height: 10 μm, cell size: 15000 μm 2 ).

[0124] The obtained shaped film was used for the above-mentioned evaluations (1) to (7). The results are shown in Table 1.

Embodiment 2

[0126] A shaped film (thickness: 46 μm, protrusion height: 5 μm, cell size: 5000 μm) was obtained in the same manner as in Example 1 except that the embossing roll was changed. 2 ).

[0127] The obtained shaped film was used for the above-mentioned evaluations (1) to (7). The results are shown in Table 1.

Embodiment 3

[0129]A methacrylic resin (manufactured by Kuraray Co., Ltd., product name "PARAPET HR-S") was put into a single-screw extruder, and melt-extruded at 260° C. to obtain a substantially flat film with a thickness of 55 μm. A photopolymerization initiator (manufactured by Ciba Specialty Chemicals, trade name) was added to 95 parts by weight of urethane acrylate (manufactured by Shin-Nakamura Chemical Co., Ltd., trade name "NK Oligo U-108A") on the surface of the film. "IRGACURE 184") 5 parts by weight of UV-curable resin, after transferring the concavo-convex shape to the coating surface, UV-curing the resin to obtain a shaped film (thickness: 55 μm, convex height: 5 μm, cell size: 10000 μm 2 ).

[0130] The obtained shaped film was used for the above-mentioned evaluations (1) to (7). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap