Bale opener for opening pressed fiber bales

A bale unpacking machine and fiber technology, which is applied in fiber unpacking, fiber processing, textiles and papermaking, etc., and can solve problems such as complex air guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

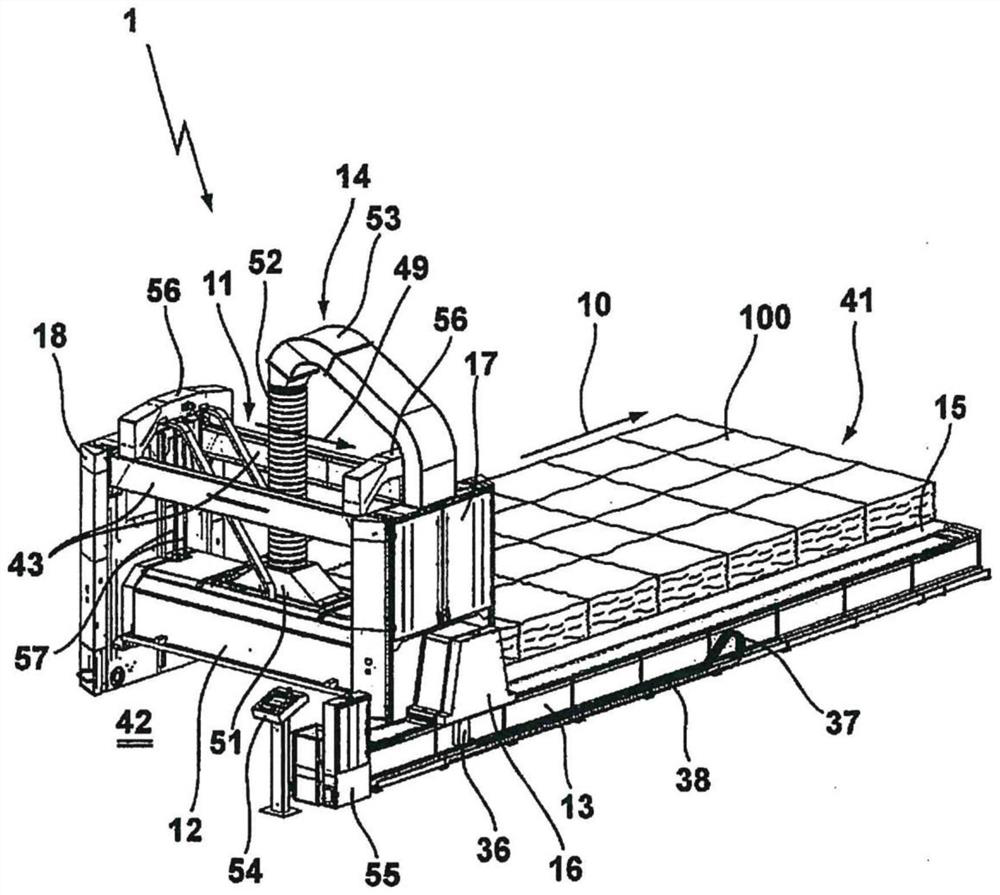

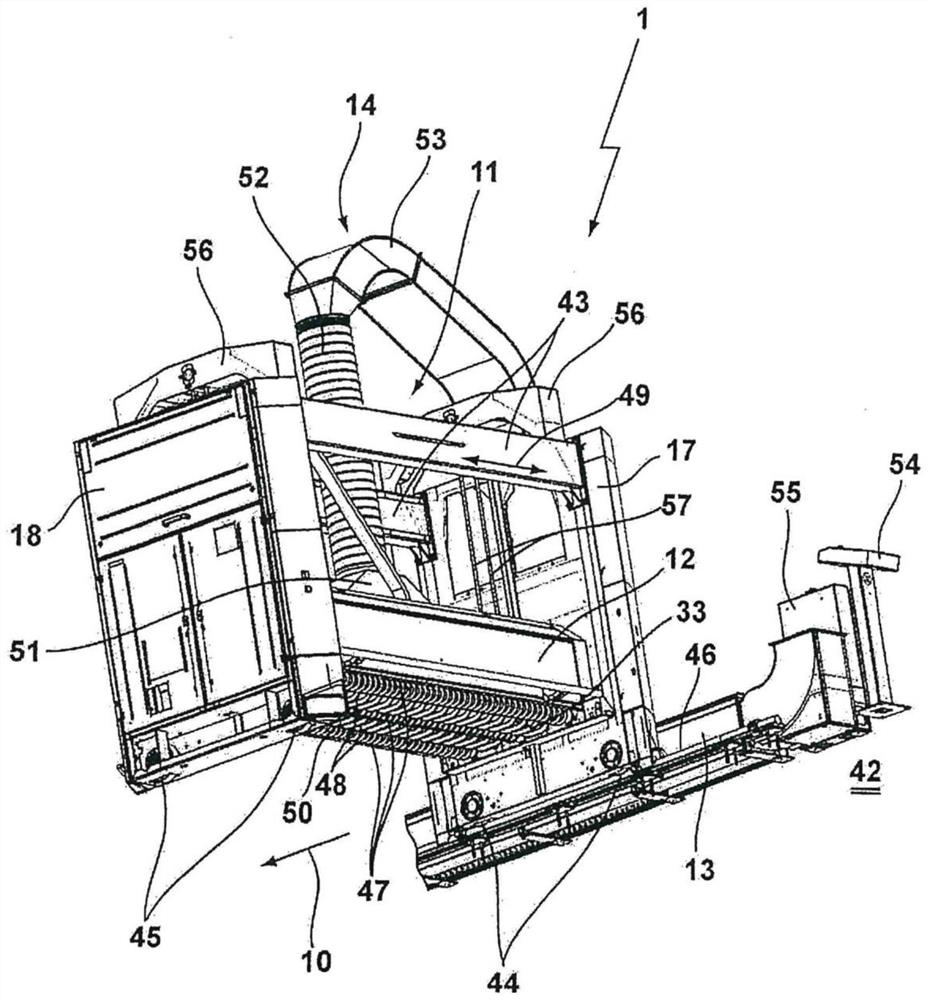

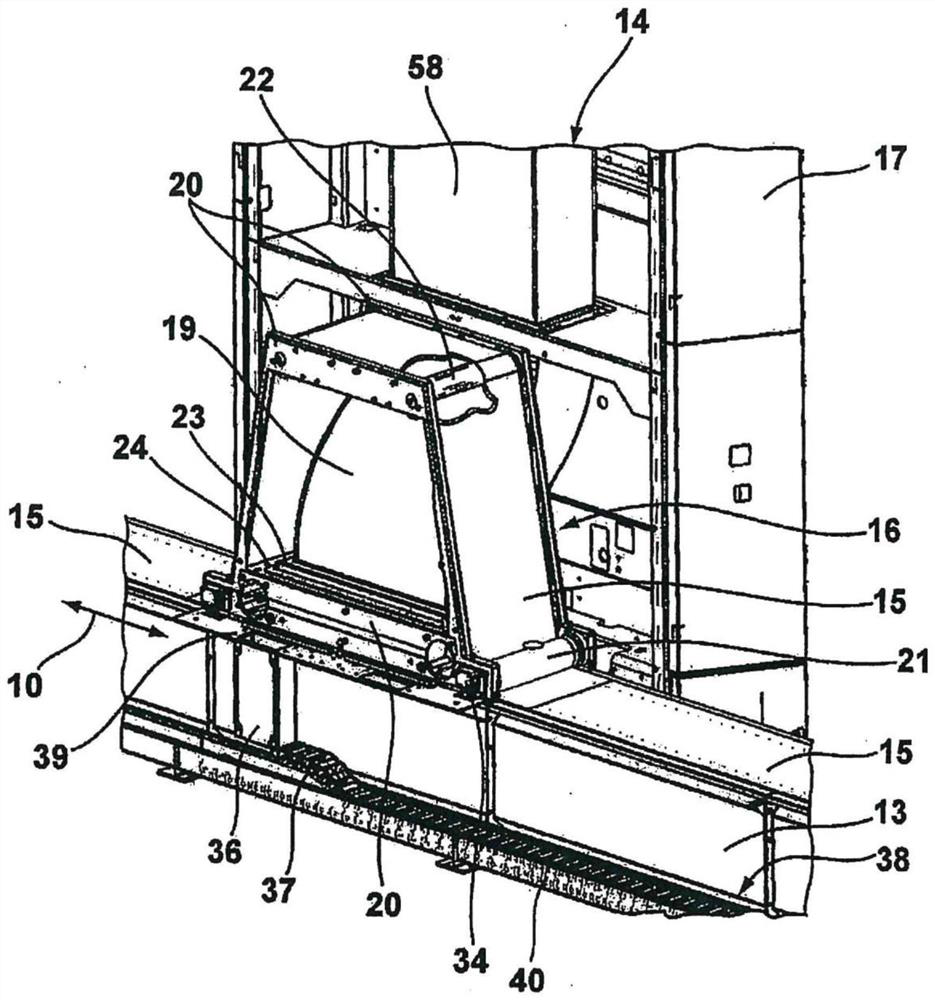

[0040] figure 1 and figure 2 In two different perspective views, a bale opener 1 is shown, which is used to remove fiber bales 100 on the upper side, which are arranged in a plurality of rows next to each other in a placement direction 10 in a placement area 41 on a base 42 . In order to chip off the upper side of the fiber pack 100 , a pick-up unit 12 is used, which is accommodated on the machine frame 11 so that it can travel in the vertical direction. The machine frame 11 has a first side frame 17 and a second side frame 18 , between which two side frames 17 and 18 extend two door profiles (gantry profiles) 43 arranged at a distance from one another.

[0041] The side frames 17 and 18 have rolling rollers (working rollers) 44 and 45, and in order to guide the machine frame 11 in the setting direction 10 a slide rail (guide rail) 46 is used, the rolling rollers 44 at the first side frame 17 at the is guided on the slide rail. The running rollers 45 on the underside on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com