Light diffusion film, and polarizing plate provided with light diffusion film

A light-diffusing, light-diffusing layer technology, applied in the direction of optics, polarizing elements, optical elements, etc., can solve the problems of difficulty in combining processability and other characteristics, difficulty in stable production, fracture, etc., and achieve excellent processability and optical characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0133]

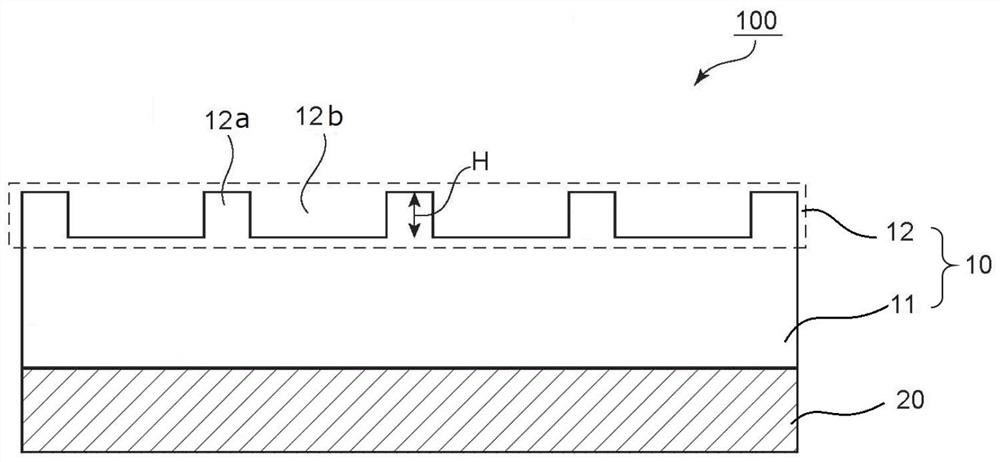

[0134] The methacrylic resin (Cola-Based Co., Ltd., product name "PARAPET HR-S") is put into a single screw extruder, and while melting and extruding at 260 ° C, the embossing roller is used to give a concave and convex shape to a surface, and the enrichment layer (thickness: 50 μm, convex height: 10 μm, cell size: 15000 μm) is obtained 2 )。

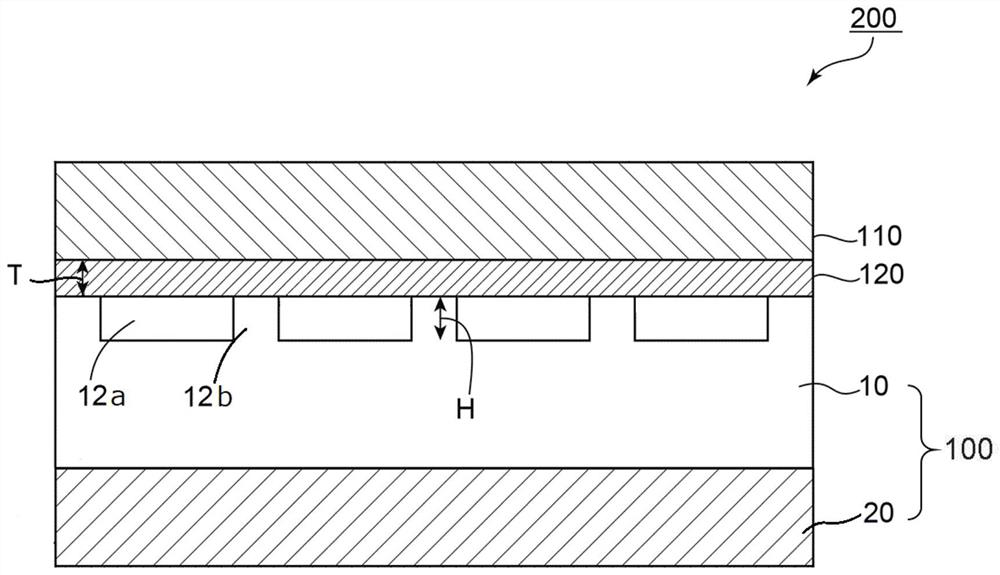

[0135] The non-concave shape of the fusing layer is coated with a mixture of 10 parts of silica particles with an average particle size of 10 μm in an acrylic UV curing resin to obtain a mixture. The coating layer is irradiated with ultraviolet rays and the ultraviolet curing resin is cured to form a light diffusion layer, and a light diffusion film is obtained.

[0136] The resulting light diffusion film is provided for the above evaluation (1) ~ (3). The results are shown in Table 1.

Example Embodiment

[0137]

[0138] As a photodiffusion layer of silica particles, using a volume average particle size of 6 μm silica particles, in addition to the same as Example 1 to obtain a light diffusion film.

[0139] The resulting light diffusion film is provided for the above evaluation (1) ~ (3). The results are shown in Table 1.

Example Embodiment

[0140]

[0141] As a photodiffusion layer of silica particles, using a volume average particle size of 2 μm silica particles, in addition to the same as Example 1 to obtain a light diffusion film.

[0142] The resulting light diffusion film is provided for the above evaluation (1) ~ (3). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap