Cleaning and hanging device and method for garment production and processing

A hanging device and clothing technology, applied in the field of clothing production, can solve problems such as unfavorable cleaning and dust removal on the surface of clothing, and achieve the effect of ensuring cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

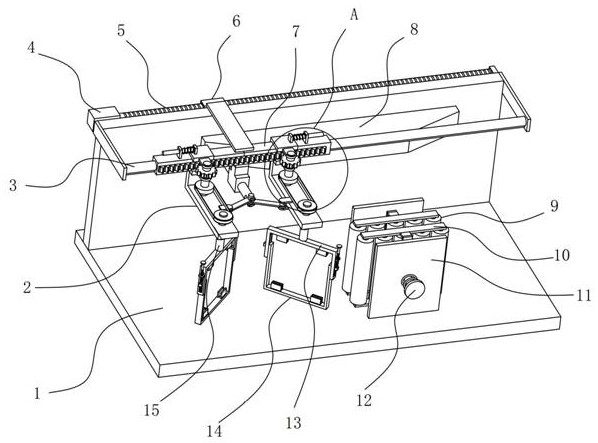

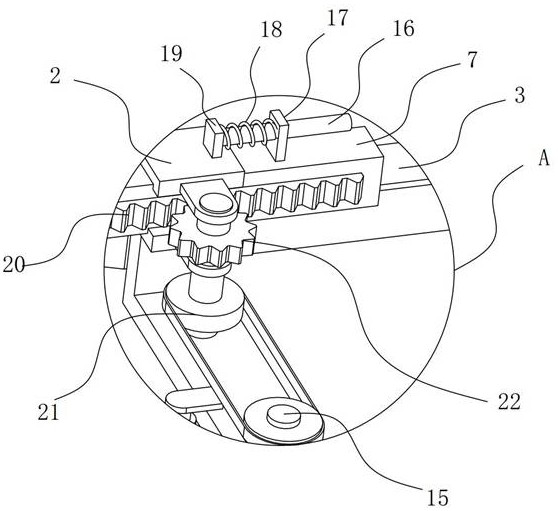

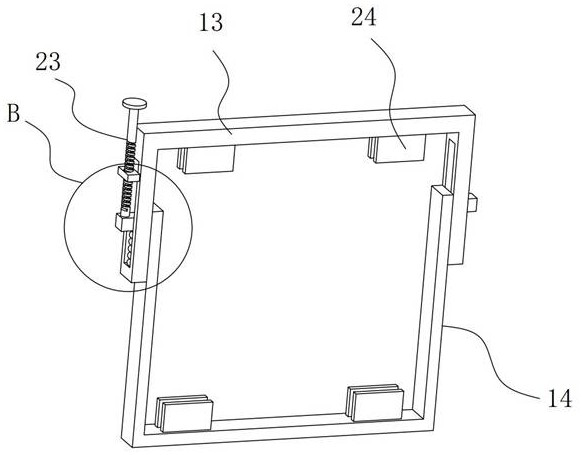

[0036] see Figure 1-8 , a cleaning hanging device for clothing production and processing, comprising a support frame 1, a guide rod 3 is fixed on the support frame 1, a conveying sleeve block 7 is slidably installed on the guide rod 3, a cleaning component is installed on the support frame 1, and the conveying sleeve is installed on the support frame 1. A support block 25 is installed at the bottom of the block 7, a drive rod 26 is slidably installed on the support block 25, and a push limit assembly is installed between the drive rod 26 and the support frame 1,

[0037] Two sliding frames 2 symmetrically arranged with respect to the driving rod 26 are slidably installed on the conveying sleeve 7, and a driven rod 28 is hinged between each sliding frame 2 and the driving rod 26, and a rotating shaft 15 is rotatably installed on the sliding frame 2, A rotary drive assembly is connected between the sliding frame 2 and the conveying sleeve block 7, and the rotary drive assembly ...

Embodiment 2

[0043] see Figure 1-8, On the basis of Embodiment 1, in addition, a servo motor 4 is installed on the support frame 1, the output shaft of the servo motor 4 is coaxially connected with a drive screw 5, and the drive screw 5 is threadedly connected with a sliding block fixed with the conveying sleeve 7. Transfer the sleeve block 6. After starting the servo motor 4, the servo motor 4 can drive the driving screw 5 to rotate, and the driving screw 5 drives the sliding sleeve block 6 to move. The sliding frame 2 , the rotating shaft 15 , the fixing frame 13 and the sliding frame 14 are moved and conveyed to realize the moving effect on the clothing.

[0044] The push-limiting component of the device includes a limit block 8 fixed on the support frame 1 . Both ends of the limit block 8 are provided with wedge surfaces 31 , and one end of the driving rod 26 away from the driven rod 28 is rotatably installed with a limiter. The guide wheel 27 that the bit block 8 abuts against.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com