Comprehensive energy supply service station oil gas recovery system fault detection method oriented to data scarce scene

An oil and gas recovery system, data-oriented technology, applied in data processing applications, neural learning methods, instruments, etc., can solve the problems of lack of historical fault samples, inability to detect timely and effectively, insufficient sample size of a single oil gun system for modeling, etc. , to achieve the effect of improving accuracy and ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

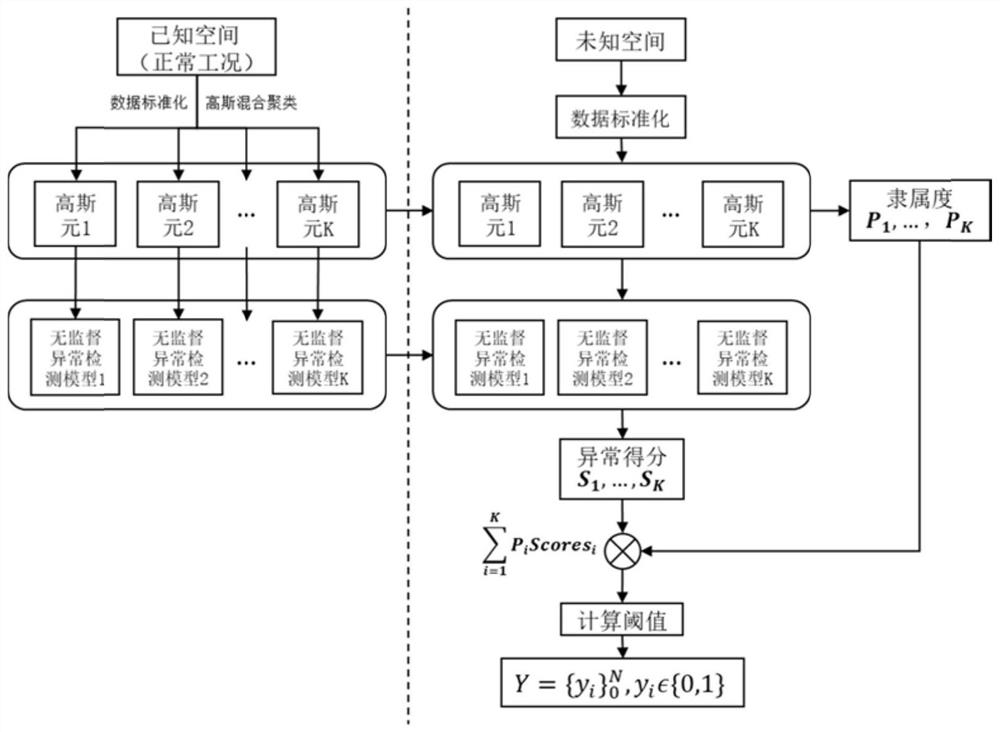

[0032] The present invention provides a fault detection method for an oil and gas recovery system of a comprehensive energy supply service station oriented to a data scarcity scenario, the method comprising the following steps:

[0033] Collect the variable data of the oil and gas recovery process of the oil and gas recovery system of the integrated energy supply service station;

[0034] Calculate the membership degrees of the current oil and gas recovery process variable data to K categories; the K categories are obtained by dividing the oil and gas recovery process variable data set based on the historical normal operation of the oil and gas recovery system of the comprehensive energy supply service station;

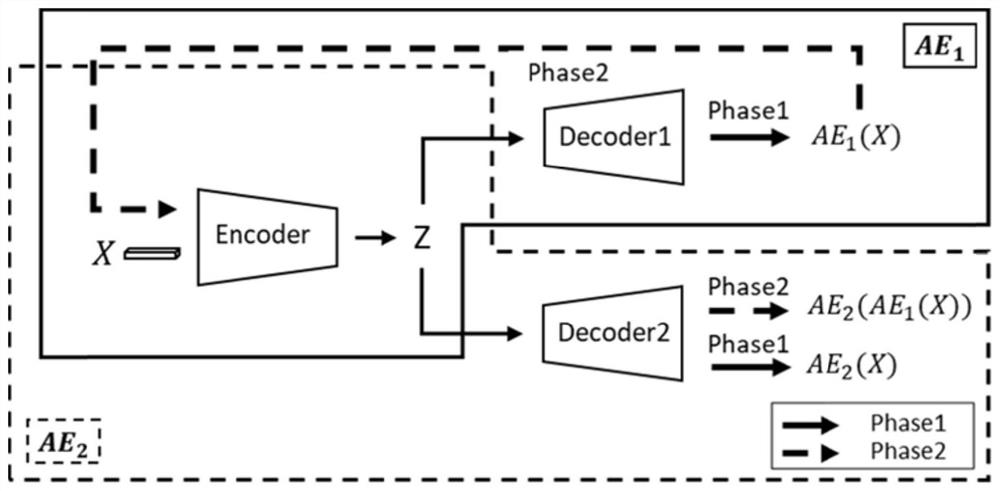

[0035] Based on the K trained unsupervised anomaly detection models, the anomaly scores of the current oil and gas recovery process variable data for each category are calculated; the K unsupervised anomaly detection models are based on the historical normal operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com