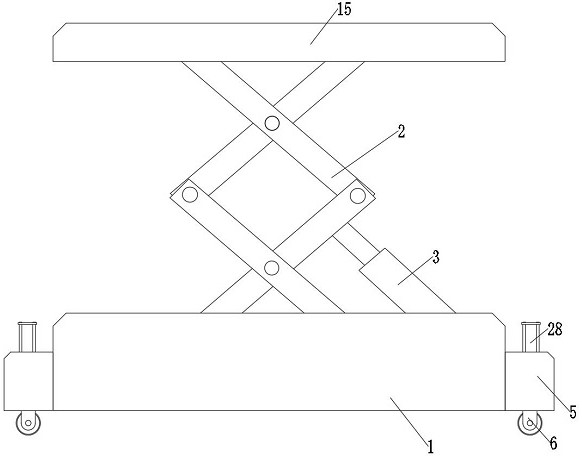

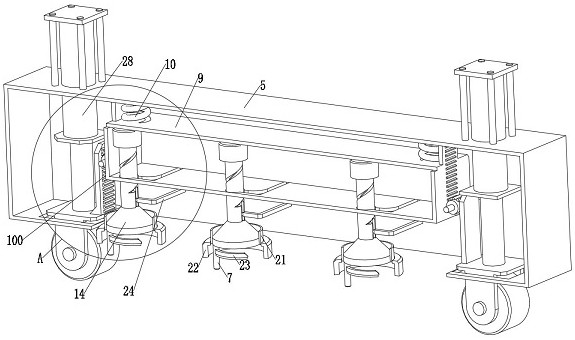

Omnidirectional moving platform with lifting structure for stage

A technology of omnidirectional movement and lifting structure, which is applied in the direction of applications, household appliances, manual sweeping machines, etc., to achieve the effect of firm adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

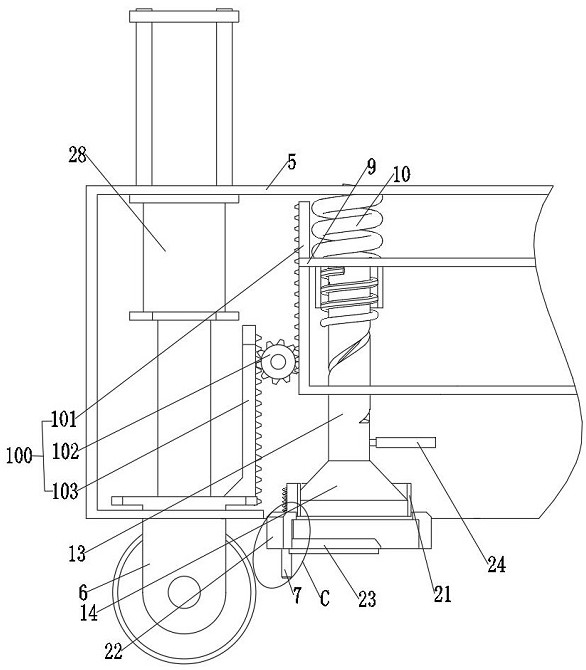

[0029] In this example:

[0030] Example 4

[0031] In this example:

[0032] Example 5

Embodiment 2

[0035] In this example:

Sewage cleaning: Since the sponge wiper 23 is wetted and then cleaned the ground, after the sponge wiper 23 is filled with liquid for many times, its internal liquid will definitely overflow on the ground, and the sponge wiper 23 will definitely adhere to it after many times of use Impurities affect the use, so a collection ring 90 is installed on the sliding ring 22, according to Figure 6 As shown, when the sponge wiper 23 rotates to the inside of the sliding ring 22, the collection ring 90 touches the ground and slides upwards, and the conical block 91 on the collection ring 90 is used to squeeze the sponge wiper 23 for maintenance, and then the sponge wiper 23 The sewage falls on the inside of the collection ring 90, and the impurities attached to the sponge wipe 23 will also be washed down by the sewage, so that the sponge wipe 23 can be automatically maintained after wetting the ground, which is convenient for use.

[0036] It should be noted th...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com