Testing method of gas drilling impact power tool

A technology of power tools and testing methods, applied in impact testing, testing of mechanical components, testing of machine/structural components, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

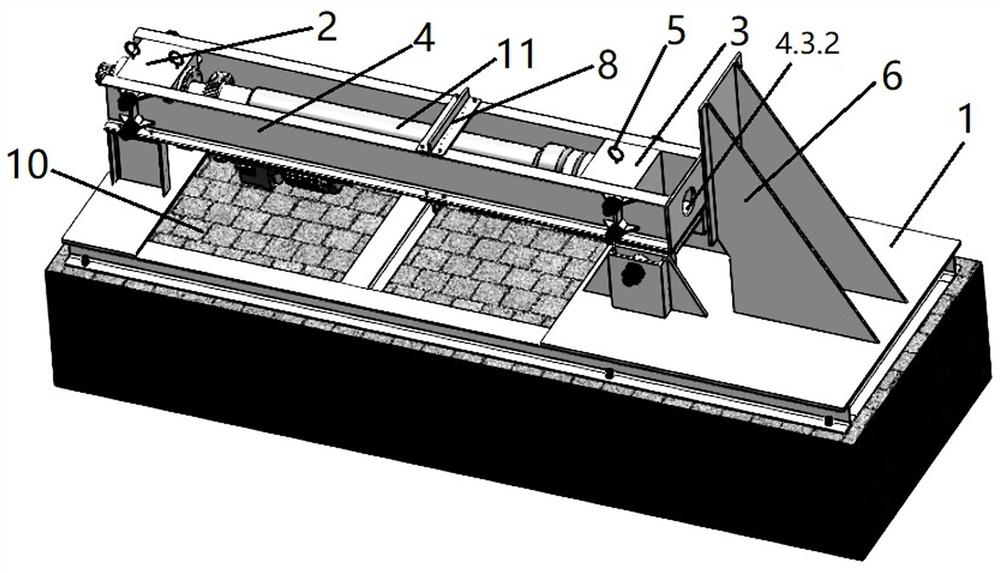

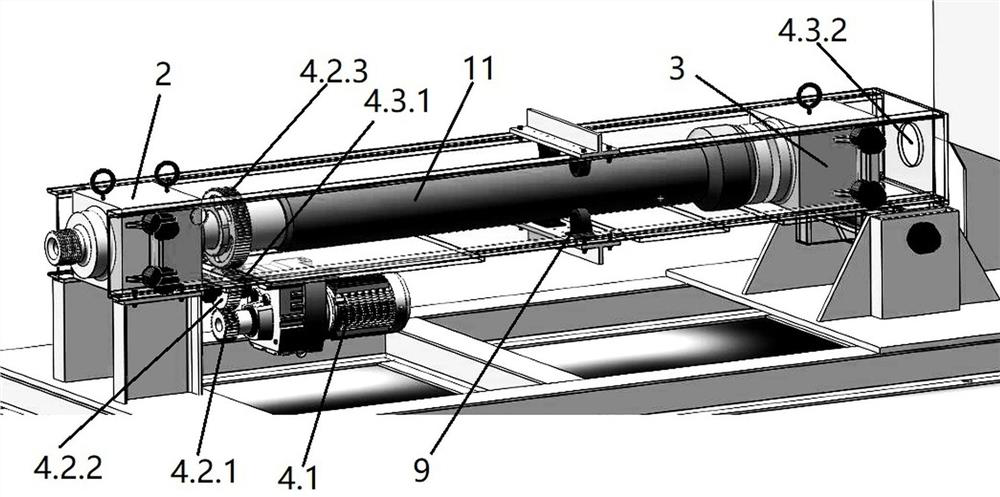

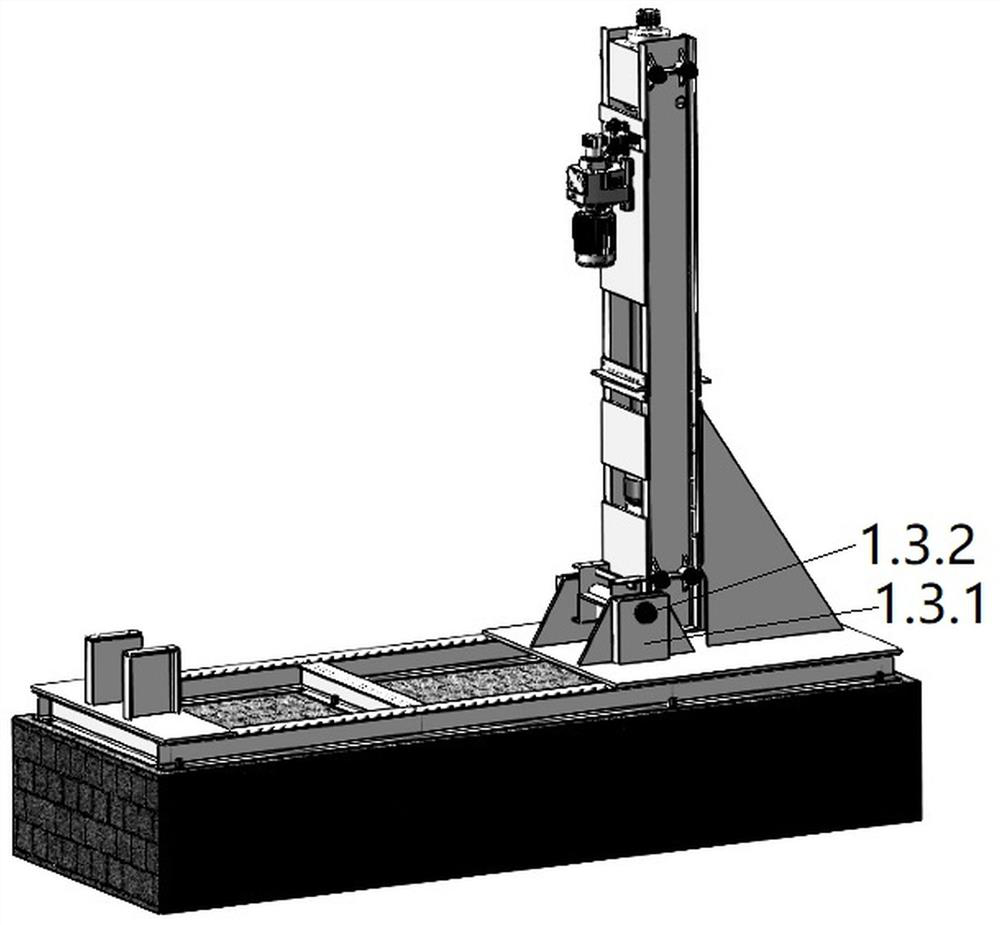

Embodiment 1

[0056] This embodiment discloses a test device for a gas drilling impact power tool. As a basic embodiment of the present invention, it includes a data processing system and a bench device. The bench device includes a support base 1, an air intake assembly 2, and a tailstock Assembly 3 and installation of rotating mechanism 4. The data processing system includes a signal acquisition unit 12 arranged on the bench device and a signal transmission unit, a data integration unit and a data processing unit electrically connected in sequence, and the signal acquisition unit 12 is electrically connected to the signal transmission unit. The support base 1 includes a positioning mounting frame 1.1 and a first supporting frame 1.2 and a second supporting frame 1.3 respectively fixed on the top of the positioning mounting frame 1.1; the air intake assembly 2 includes an air intake seat 2.1, a bearing 2.2 and an air intake pipe 2.3; The inside of the air seat 2.1 is provided with an air in...

Embodiment 2

[0109] The installation of the test bench includes the following steps: S11, fixing the support base 1 welded with steel plates on the cement pier 10; S12, installing the installation rotation mechanism 4 on the top of the support base 1; S13, and then installing the The air assembly 2 and the tailstock assembly 3 are respectively installed at the two ends inside the installation rotating mechanism 4; S14 is connected to the air supply equipment on the air intake assembly 2;

[0110] The arrangement of the data processing system includes the following steps: S21, electrically connecting the signal acquisition unit 12, the signal transmission unit, the data integration unit and the data processing unit sequentially to form a data processing system; S22, arranging the signal acquisition unit 12 on the tailstock The inside of the assembly 3 is used to collect the impact signal that the tested tool 11 acts on the tailstock assembly 3;

[0111] The installation of the tested tool 1...

Embodiment 3

[0115]

[0116] Among them, W is the impact energy of the hammer, Fmax is the maximum impact energy of the hammer, and a, b, and c are all constants; S442 is to calibrate the piezoelectric quartz force sensor, that is, to use MATLAB software to calibrate the same hammer from different The data obtained from the height free fall is subjected to curve fitting to obtain the relationship curve between impact force and impact energy, and the values of constants a, b and c are obtained by combining the fitting curve results to complete the calibration of the piezoelectric quartz force sensor.

[0117] Example 9

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com