Electrically-controlled brake test bench

A test bench, electronically controlled braking technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., to achieve the effects of low cost, simple hardware environment, and low modification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

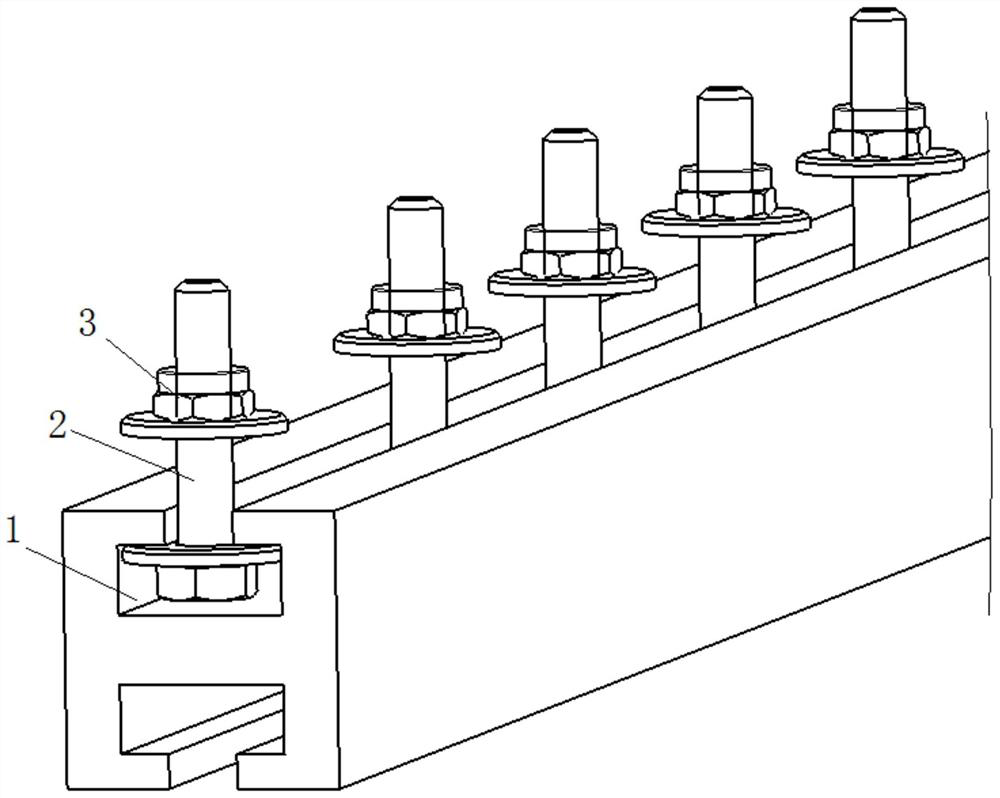

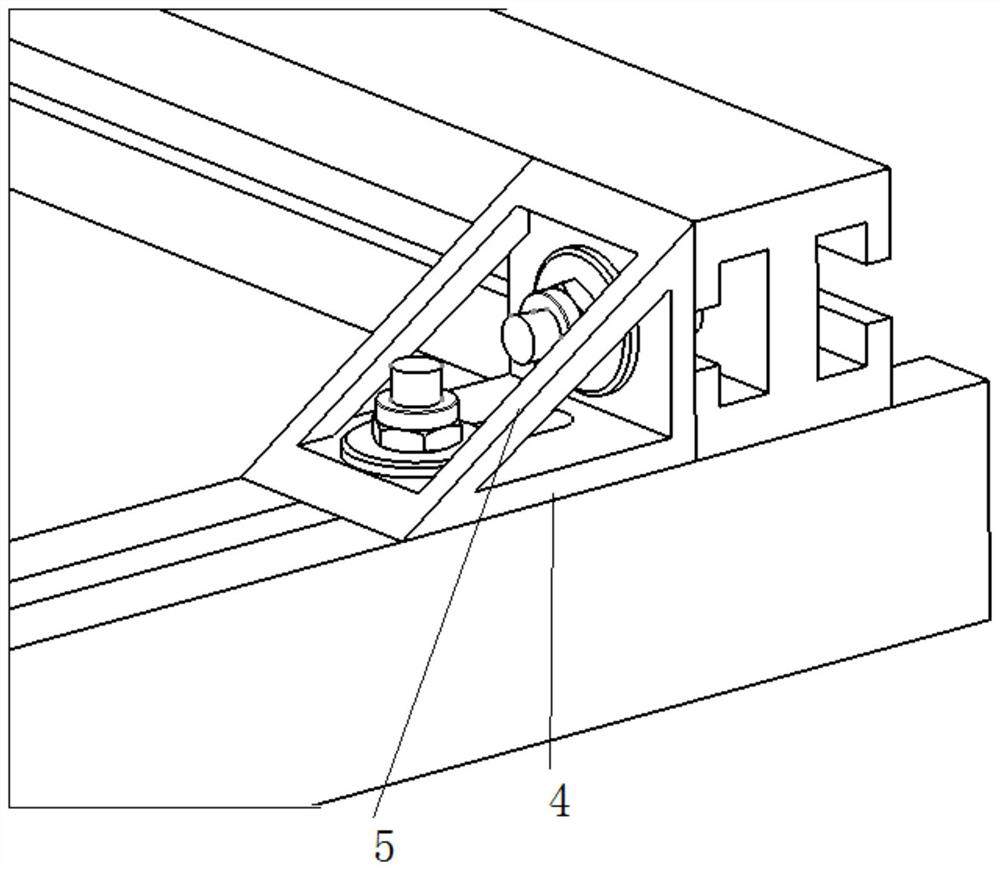

Method used

Image

Examples

Embodiment Construction

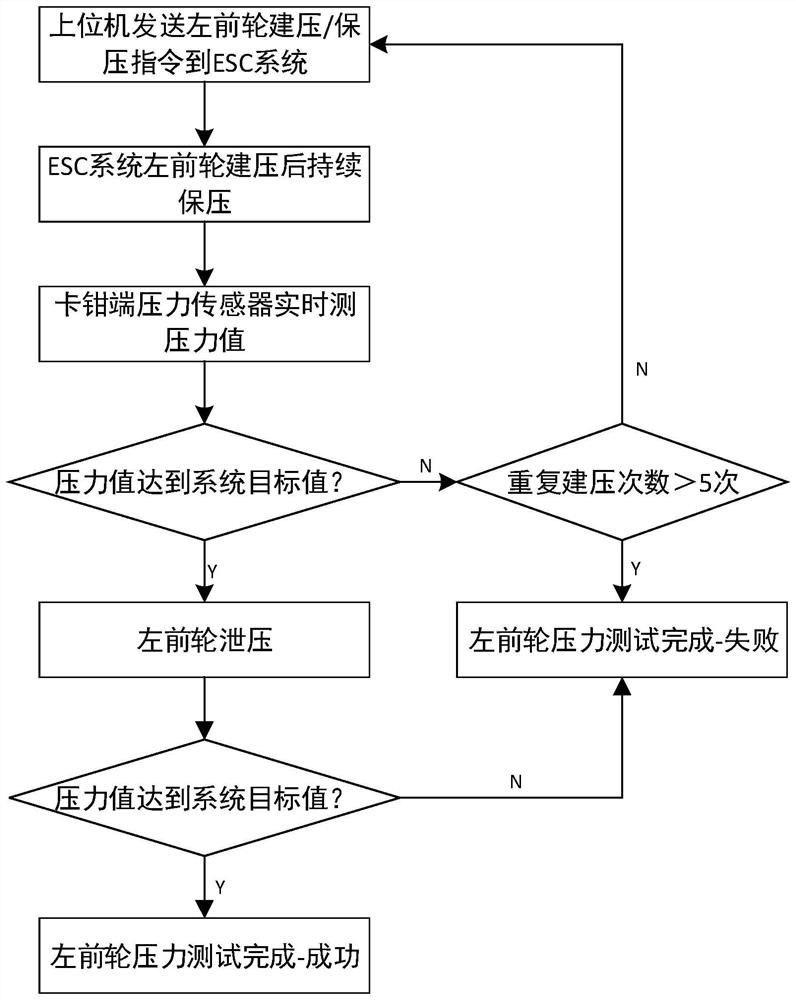

[0025] If the locked target pressure is reached within this pressure buildup cycle, the system will continue to enter the pressure hold phase within the command interval time. When the upper computer sends a pressure release command, the ESC system closes the liquid inlet valve and opens the liquid outlet valve according to the process, and the pressure in the ESC system is quickly released.

[0026] The pressure sensor feeds back the system pressure value in real time. After a fixed time after the pressure relief command is issued, if the pressure drops below the threshold value, the pressure relief is completed, otherwise the pressure relief fails.

[0027] After all the above processes are completed, the ESC system pressure building capability test link is completed. In the follow-up, complete the system pressure building ability test of other rounds in the order of left front-right front-left rear-right rear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com