Assembling device for installing torsion rod spring

A technology for assembling devices and torsion bar springs, which is applied to vehicle springs, elastic suspensions, transportation and packaging, etc., and can solve problems such as difficulty in using pressure equipment, devices, smooth installation of interference, and failure of torsion bar springs. Achieve the effect of ensuring mass production requirements, light weight and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

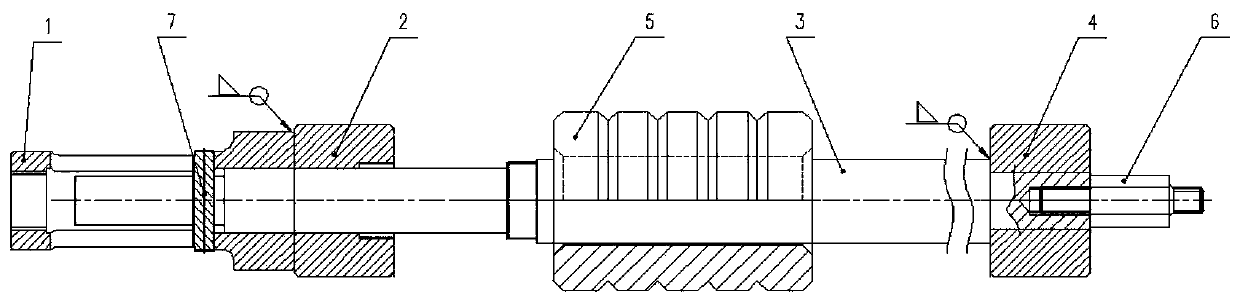

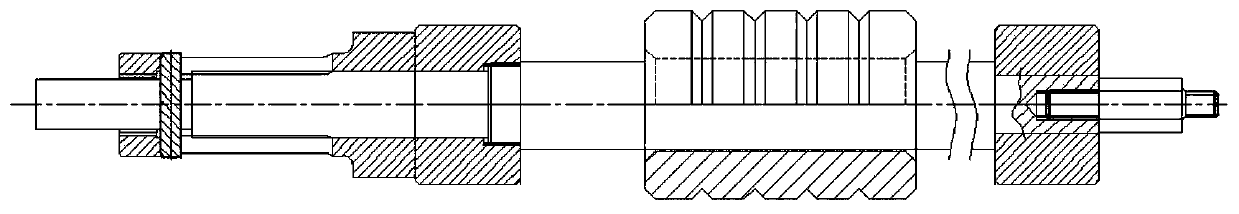

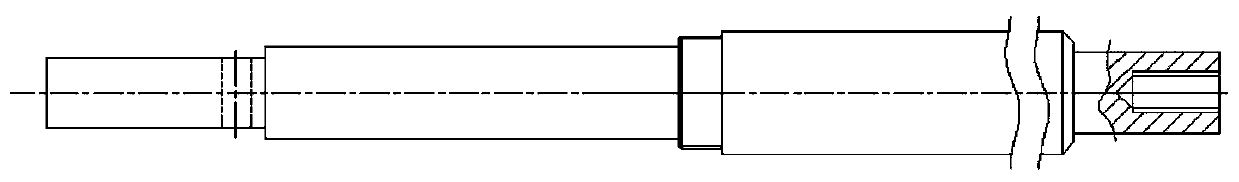

[0029] This embodiment proposes an assembly device for torsion bar spring installation, its structure is as follows figure 1 and 2 Shown, comprise the main bar 3 (structure such as image 3 shown), the threaded sleeve 2 connected and positioned with the main rod 3, the positioning block 4 positioned with the car body spline fixed position, and the spline head 1 positioned with the spline (structure such as Figure 4 shown) and bolt head 6 (structure as Figure 5 Shown), the positioning pin 7 of the positioning tool state and the force tool knocking hammer 5.

[0030] Wherein, the spline head 1 and the threaded sleeve 2 are welded together, the main rod 3 passes through the middle of the threaded sleeve 2, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com