Novel tunnel liquid ammonia instant freezer

A technology of quick freezer and liquid ammonia, which is applied to lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve the problems of long freezing time, slow conveying speed of conveyor belt, low production efficiency, etc. High efficiency and good freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

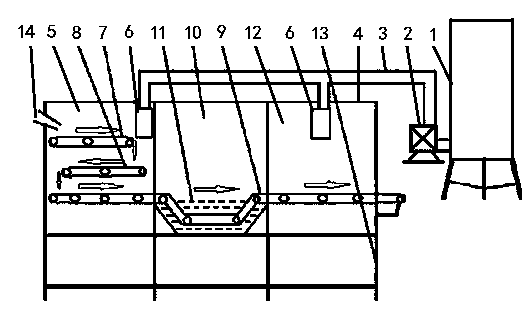

[0011] like figure 1 As shown, a novel tunnel liquid ammonia quick freezing machine is characterized in that it is composed of a liquid ammonia storage tank 1, a refrigeration compressor 2, a liquid ammonia delivery pipe 3, a quick freezing machine 4, a freezing chamber 5, an evaporator 6, and a freezing conveyor belt armor 7 , Freezing conveyor belt B 8, conveyor belt 9, ice coat room 10, ice pool 11, ice-solid chamber 12, quick-freezing machine support 13, quick-freezing machine feed port 14 composition. The liquid ammonia storage tank 1 is made of a steel plate with a thickness of 0.8 cm, 6 m in height and 2.5 m in diameter. The liquid ammonia storage tank 1 has a double-layer structure of an inner tank and an outer tank. 3 with a diameter of 10 cm, the refrigeration compressor 2 transports liquid ammonia to the evaporator 6 of the freezing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com