Self-adaptive differential mechanism facilitating stabilization of vehicle body

A body stabilization and differential technology, which is applied in the direction of differential transmission, vehicle components, transmissions, etc., can solve the problem of limited support for tilting and bending functions of the body, limited adaptation range of the differential, and inability to flexibly adapt to motor vehicles Drive types and other issues, to achieve the effect of high adaptability, easy maintenance, and low cost of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

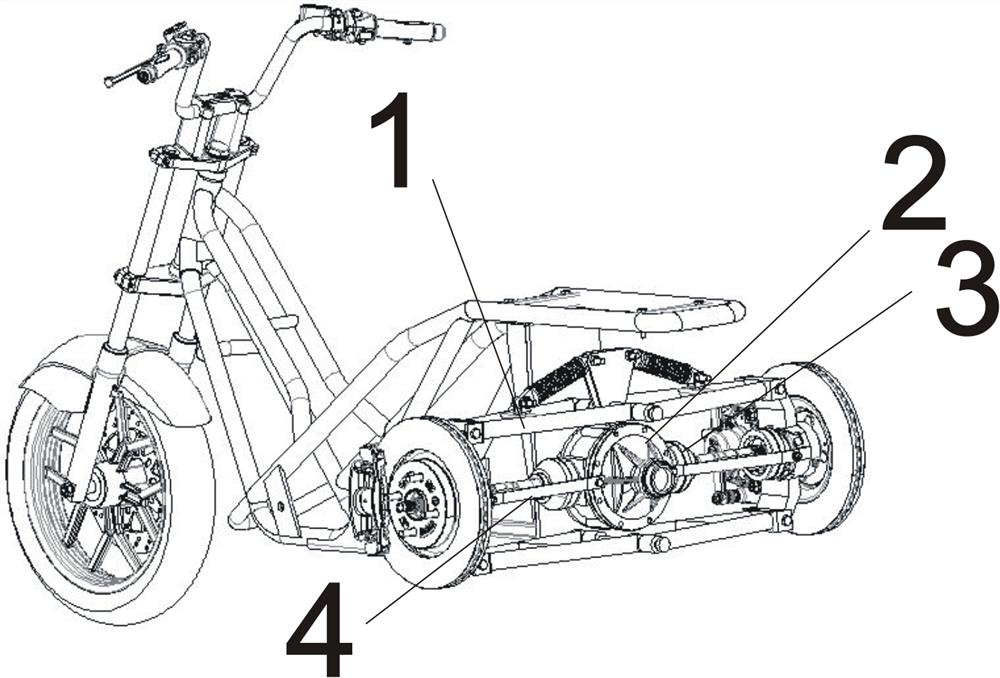

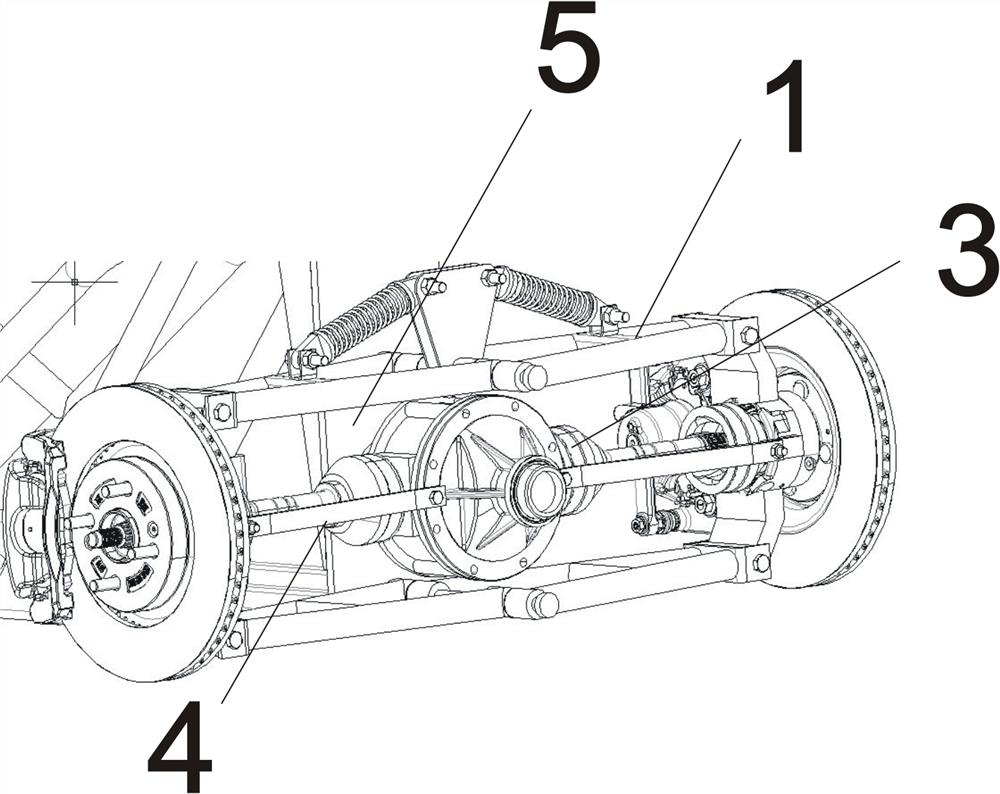

[0026] refer to figure 1 , figure 2 , image 3 , the self-adaptive differential that is beneficial to the stability of the vehicle body according to the present invention comprises a main body of the differential 2, and the shell part of the differential 2 is symmetrical front and back, that is, the front shell and the rear shell are symmetrical;

[0027] The front shell and the rear shell are vertically symmetrical and left-right symmetrical;

[0028] The differential gear 2 is rotatably arranged on the vehicle frame.

[0029] Further, the vehicle frame is provided with a fixed plate 5, and the differential gear 2 is rotatably connected to the fixed plate 5 through the fixed plate 5 and the bearing seat or the rotating sleeve.

[0030] Further, the differential 2 is power-connected to the running wheels through a constant velocity universal joint 3;

[0031] The wheel hubs on both sides of the motor vehicle are respectively hingedly arranged on the axle through the conne...

Embodiment 2

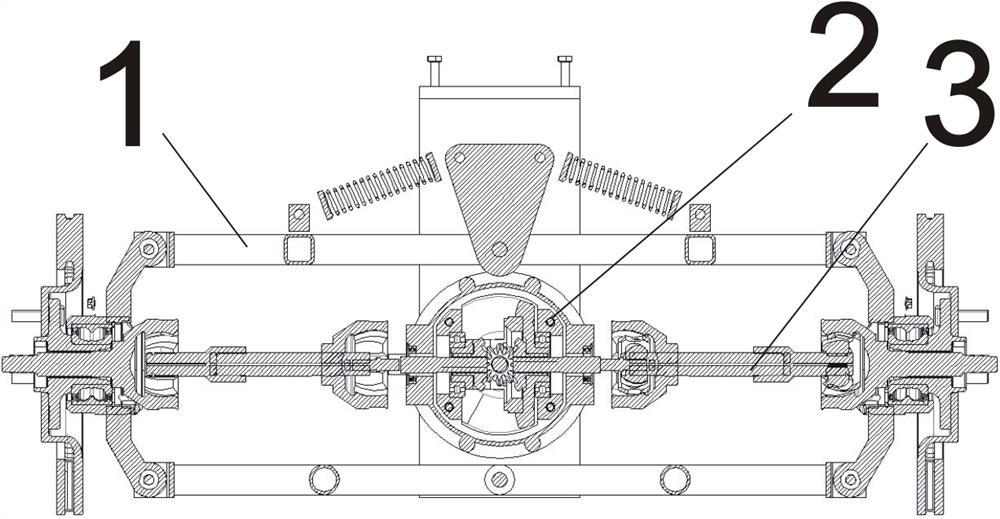

[0037] refer to Figure 4 , Figure 5 , the self-adaptive differential that is beneficial to the stability of the vehicle body according to the present invention comprises a main body of the differential 2, and the shell part of the differential 2 is symmetrical front and back, that is, the front shell and the rear shell are symmetrical;

[0038] The front shell and the rear shell are vertically symmetrical and left-right symmetrical;

[0039] The differential gear 2 is rotatably arranged on the vehicle frame.

[0040] Further, the vehicle frame is provided with a fixed plate 5, and the differential gear 2 is rotatably connected to the fixed plate 5 through the fixed plate 5 and the bearing seat or the rotating sleeve.

[0041] Further, the differential 2 is fixedly connected to the half shaft tube 6, and the half shaft tube 6 is connected to the wheel hub through the half shaft.

[0042] That is to say, the rotatable differential 2 is directly connected to the wheel hub th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com