The method to ensure the reliable grounding of the closed jet fuse in the overhaul state

A technology for overhauling state and fuse, applied in the field of safety appliances, can solve the problems of difficulty in ensuring safe operating distance, hidden dangers to the personal safety of on-site operators, etc., and achieves low cost of transformation, simplified on-site operating procedures and steps, and concise technical solutions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

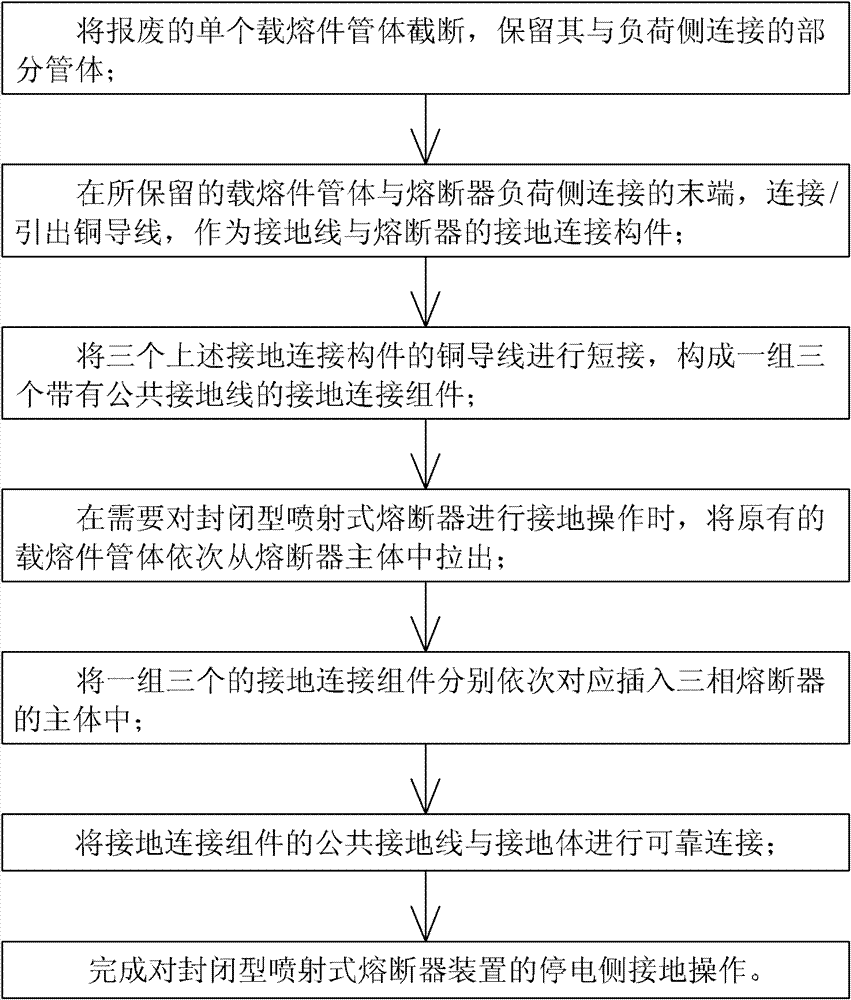

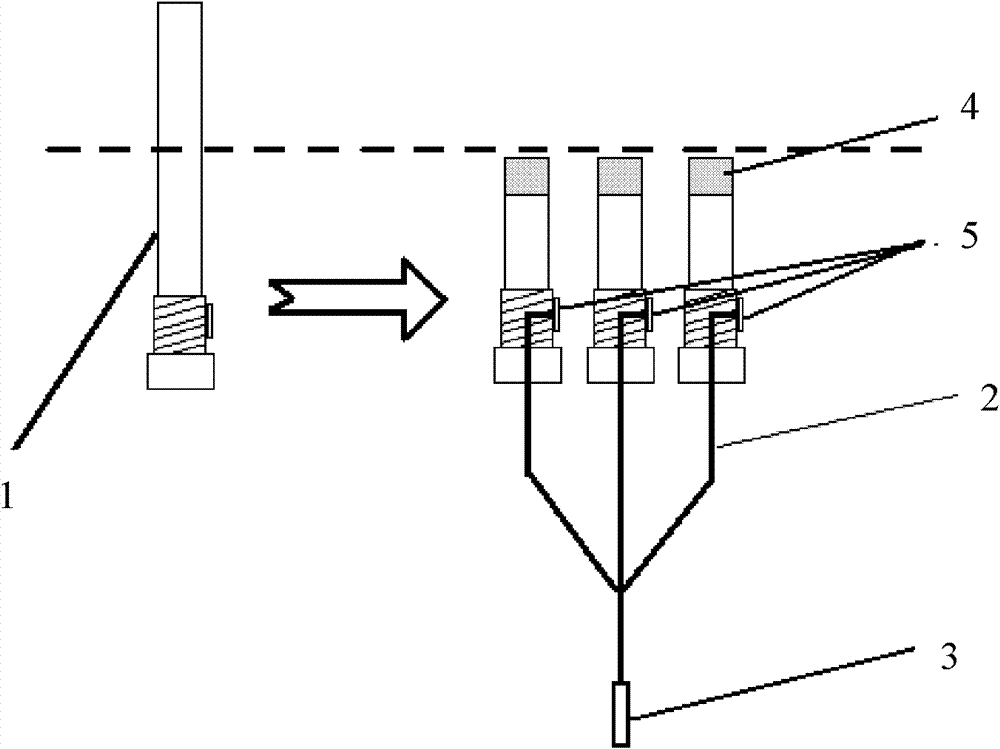

[0036] figure 1 In this method, this grounding method includes at least the following steps:

[0037] A. Cut off the scrapped single fuse-carrying part tube body, and keep part of the tube body connected to the load side;

[0038] B. At the end of the connection between the retained fuse body and the load side of the fuse, connect / lead out the copper wire as the ground connection member between the ground wire and the fuse;

[0039] C. Short-circuit the copper wires of the three above-mentioned grounding connection components to form a group of three grounding connection components with a common grounding wire;

[0040] D. When it is necessary to perform grounding operation on the closed jet fuse, pull out the original fuse body from the main body of the fuse in sequence;

[0041] E. Insert a group of three ground connection components into the main body of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com