Full-automatic needling device and using method thereof

An acupuncture device and fully automatic technology, applied in acupuncture machines, measuring devices, optical devices, etc., can solve the problems of troublesome manual operation, poor quality of finished products, low degree of automatic control, etc., and achieve simple and convenient installation and disassembly, and improve Acupuncture quality, effect of improving acupuncture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

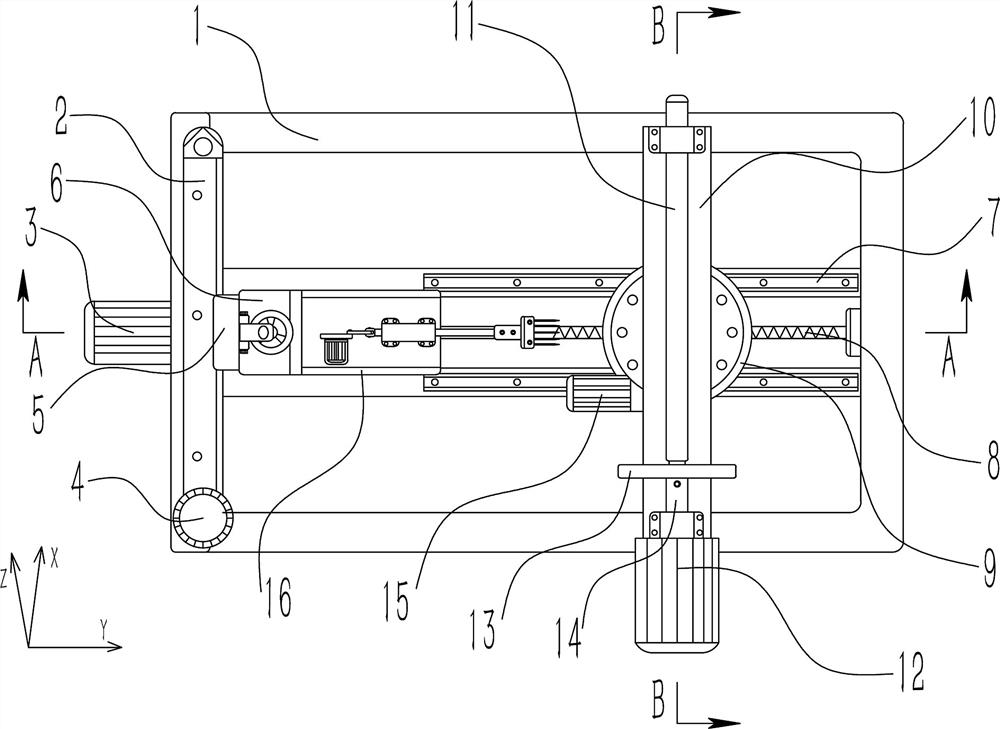

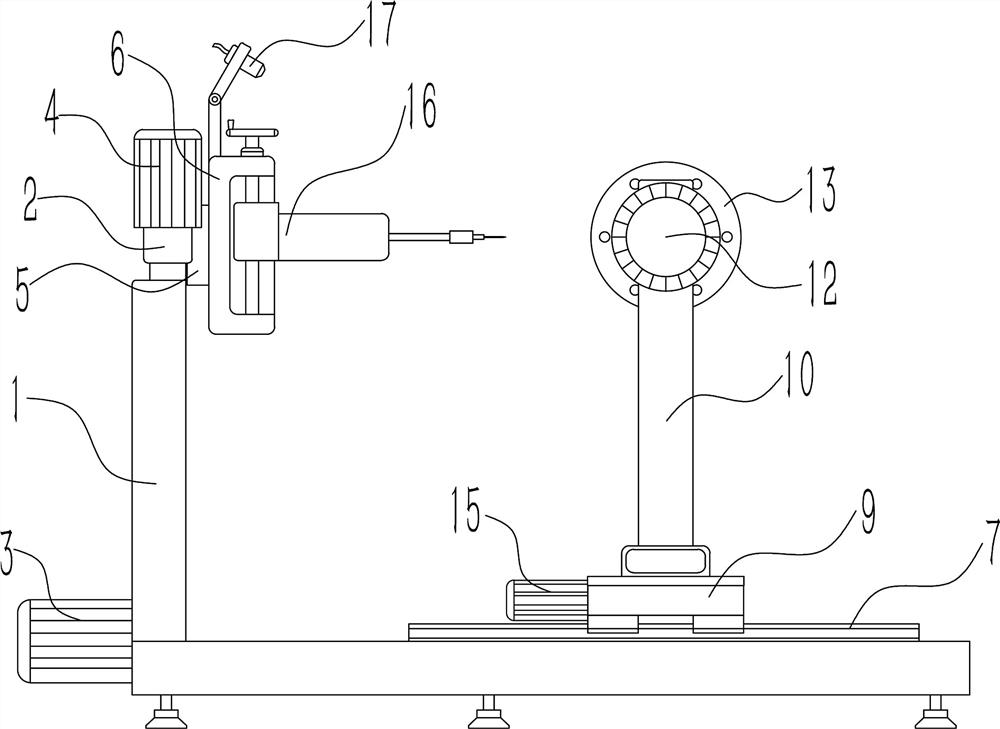

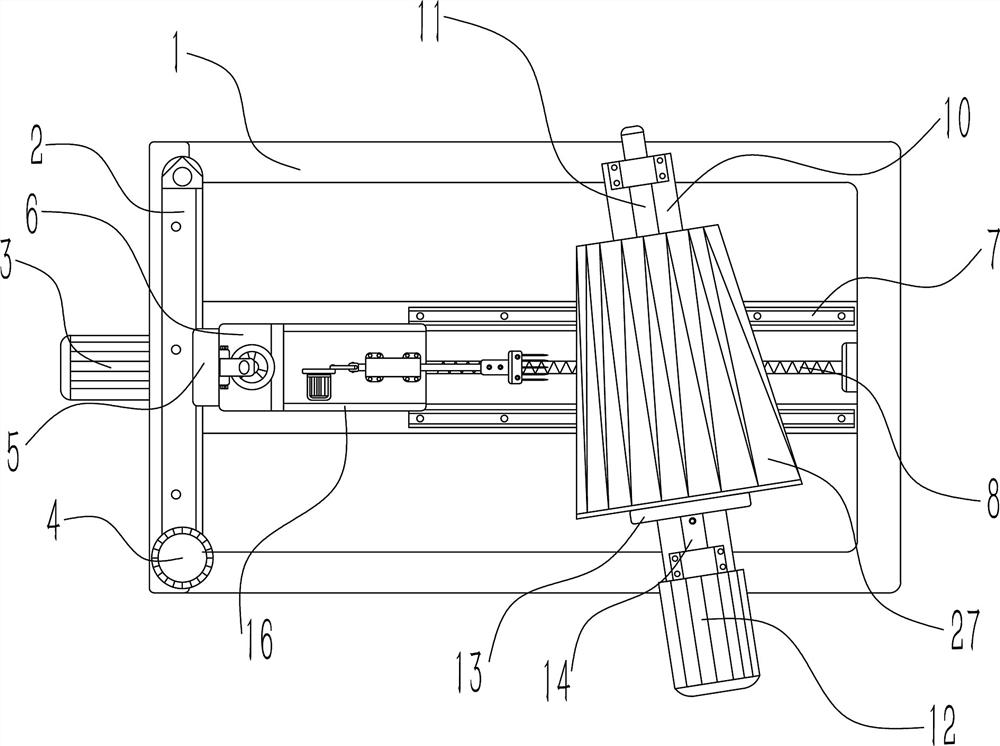

[0039] like Figures 1~7 As shown, a fully automatic acupuncture device and a method for using the same include a support frame 1, one side of the support frame 1 is provided with a C-shaped frame 6 that moves in the X-axis direction, and the C-shaped frame 6 is provided with a Z-axis direction. The moving acupuncture drive box 16, the other side of the support frame 1 is provided with an electric turntable 9 that moves in the Y-axis direction, the electric turntable 9 is provided with a rotating turret 10, and the end of the turret 10 is provided with a rotating and detachable rotating shaft 11. With this structure, the wooden mold 27 is fixed on the rotating shaft 11, and the turret 10 is rotated and adjusted according to the external contour of the wooden mold 27, so that the acupuncture drive box 16 is perpendicular to the wooden mold 27, and the acupuncture drive box 16 is adjusted on the C-shaped frame 6 Thereby, the needles in the acupuncture drive box 16 are horizonta...

Embodiment 2

[0052] like Figures 1~7 As shown, in conjunction with Embodiment 1, it is further explained: sliding and separating the rotating shaft 11 and the main shaft 14, the wooden mold 27 is sleeved on the rotating shaft 11, the end of the rotating shaft 11 is fixedly connected with the main shaft 14 through a pin shaft, and the end of the wooden mold 27 is fixed with bolts. The plate 13 is fixedly connected; the hand wheel 602 is manually driven, thereby driving the needle 21 to move on the Z axis, so that the axis of the needle 21 and the wooden mold 27 are on the same horizontal plane; the electric turntable 9 rotates to adjust the turret 10 and the wooden mold 27 to Make the outer surface of one side of the wooden mold 27 perpendicular to the thorn needle 21; adjust the thorn needle 21 and the wooden mold 27 for zero position determination, and simultaneously scan the external contour of the wooden mold 27 by the image detection analyzer 17; A layer of felt, the third motor 12 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com