Pile sinking device for precast pile construction

A technology of prefabricated piles and sinking piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that prefabricated piles cannot be guaranteed to sink quickly and vertically into the ground, and lack of prefabricated pile guiding mechanisms, etc., and achieve simple structure and easy use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

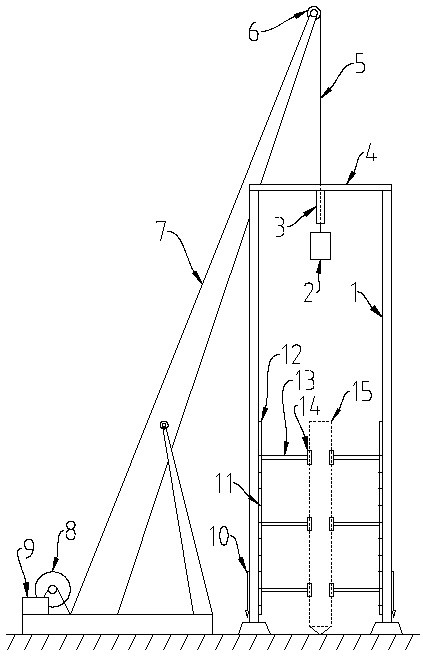

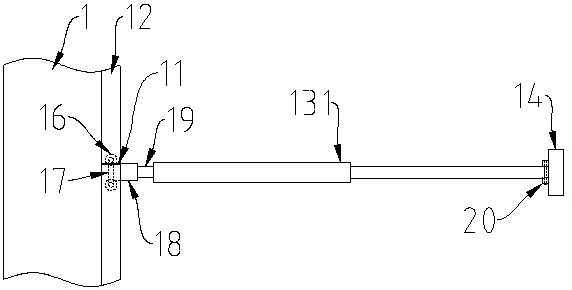

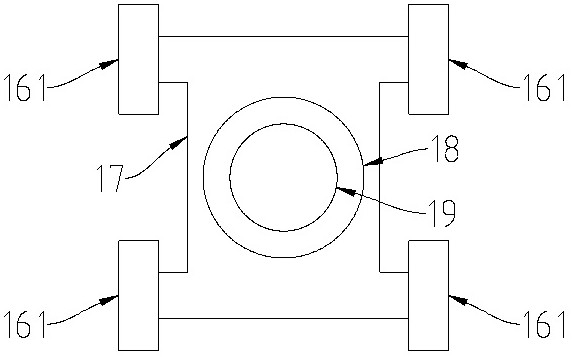

[0022] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the present invention provides a pile driving device for prefabricated pile construction, comprising three vertical piles 1 arranged in an equilateral triangle, and a vertical indicator 10 is provided on the outer side of the lower part of the pile To facilitate the vertical adjustment and indication of the pile 1.

[0024] During specific implementation, a support adjustment structure can be arranged at the bottom or around the pile 1, such as a plurality of retractable support rods surrounding the pile 1 and the lower ends are fixed relative to the ground, to help support the pile 1 to stand upright on the ground more stably, and at the same time It is convenient to adjust the pile 1 in the vertical direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com