Rapid pile forming device and pile forming method thereof

A pile forming and power device technology, applied in excavation, sheet pile walls, construction, etc., can solve the problems of high construction cost and low efficiency, and achieve the effect of improving construction quality, simple overall structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

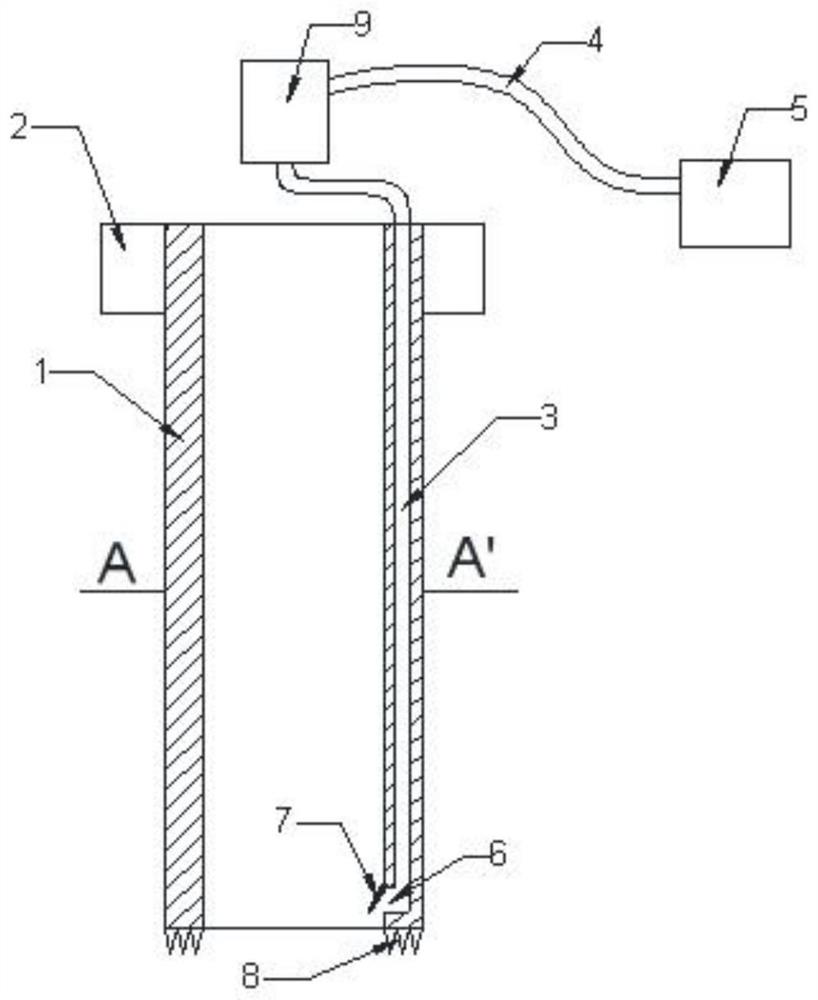

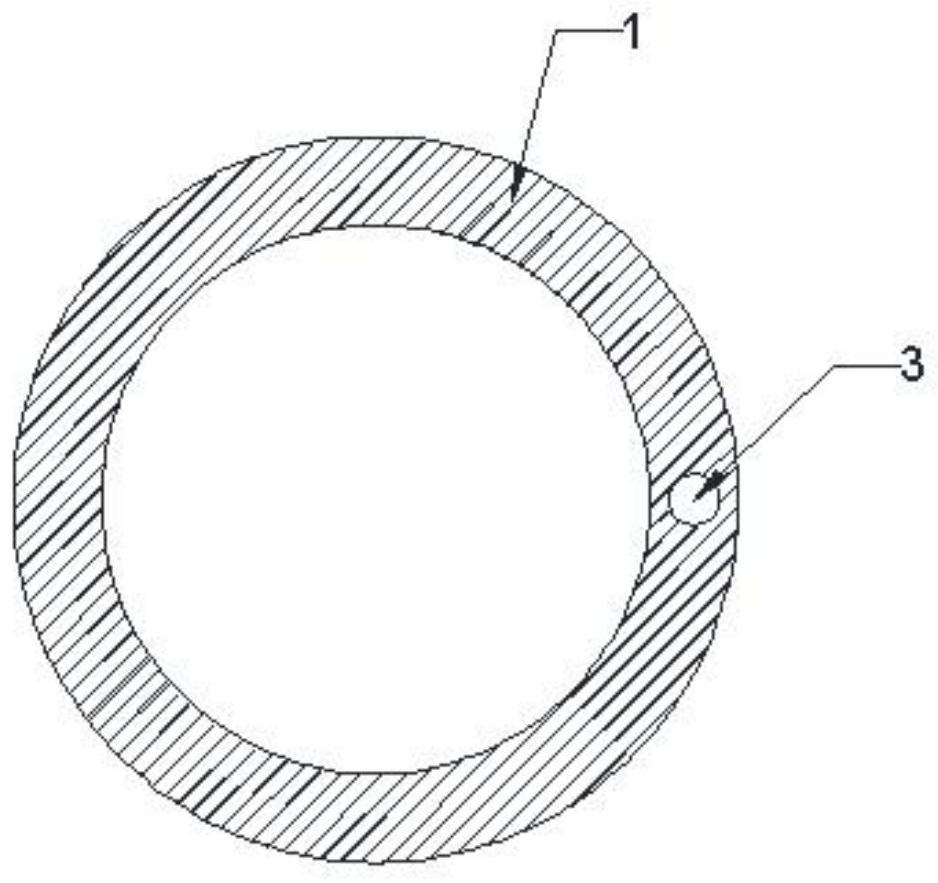

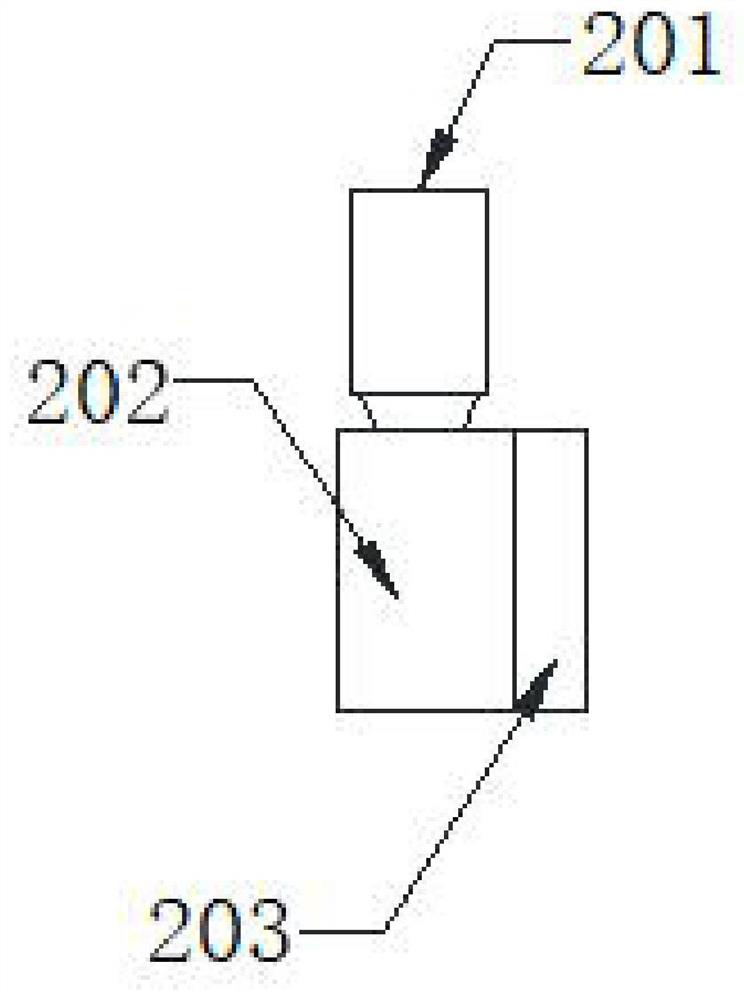

[0040] Specifically, the ventilation pipe 3 is built in parallel in the pipe wall of the ventilation sink 1, and the high-pressure airflow of the air compressor is introduced into the bottom inner wall of the ventilation sink 1 through the air pipe 3, and is released at the air outlet 6 of the inner wall. When the rapid pile forming device works, the power device 2 is activated, the power device 2 drives the ventilation sinker 1 to rotate, and a number of conical pins 8 are arranged on the lower surface of the ventilation sinker 1. When the ventilation sinker 1 descends, it encounters relatively hard When there are stones or hard soil, the conical pin 8 rotates with the ventilation immersion tube 1, which can break or loosen the harder stones or hard soil, so that the ventilation immersion tube 1 can sink into the soil more easily. When the ventilation immersion pipe 1 is sunk into the ground to a certain depth, the air compressor 5 is started, and the compressed air is filled ...

Embodiment 2

[0042] Specifically, the ventilation pipe 3 is built in parallel in the pipe wall of the ventilation sink 1, and the high-pressure airflow of the air compressor is introduced into the bottom inner wall of the ventilation sink 1 through the air pipe 3, and is released at the air outlet 6 of the inner wall. When the rapid pile forming device works, the power device 2 is activated, the power device 2 drives the ventilation sinker 1 to rotate, and a number of conical pins 8 are arranged on the lower surface of the ventilation sinker 1. When the ventilation sinker 1 descends, it encounters relatively hard When there are stones or hard soil, the conical pin 8 rotates with the ventilation immersion tube 1, which can break or loosen the harder stones or hard soil, so that the ventilation immersion tube 1 can sink into the soil more easily. When the ventilation immersion pipe 1 is sunk into the ground to a certain depth, the air compressor 5 is started, and the compressed air is filled ...

Embodiment 3

[0044] see Figure 4-Figure 6As shown, the ventilation pipe 3 can be solved by fixing the small-diameter steel pipe on the inner wall, the outer wall and the middle of the ventilation sink pipe 1 in parallel. If the ventilation tube 3 is arranged in the middle of the ventilation sink tube 1 , connecting blocks are arranged at intervals in the longitudinal direction to fix the ventilation tube 3 and the inner wall of the ventilation sink tube 1 . When the rapid piling device works, the power device 2 is activated, the power device 2 drives the ventilation sinker 1 to rotate, and a number of conical pins 8 are arranged on the lower surface of the ventilation sinker 1. When the ventilation sinker 1 descends, it encounters relatively hard When the rock or hard soil is hard, the conical pin 8 rotates with the ventilation immersion tube 1, which can break or loosen the harder stone or hard soil, so that the ventilation immersion tube 1 can sink into the soil more easily. When the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com