Method and device for predicting drilling fluid leakage of fractured formation by using DFN

A drilling fluid and formation technology, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of reduced recovery rate, loss of drilling fluid, failure to reflect downhole fractured formation loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

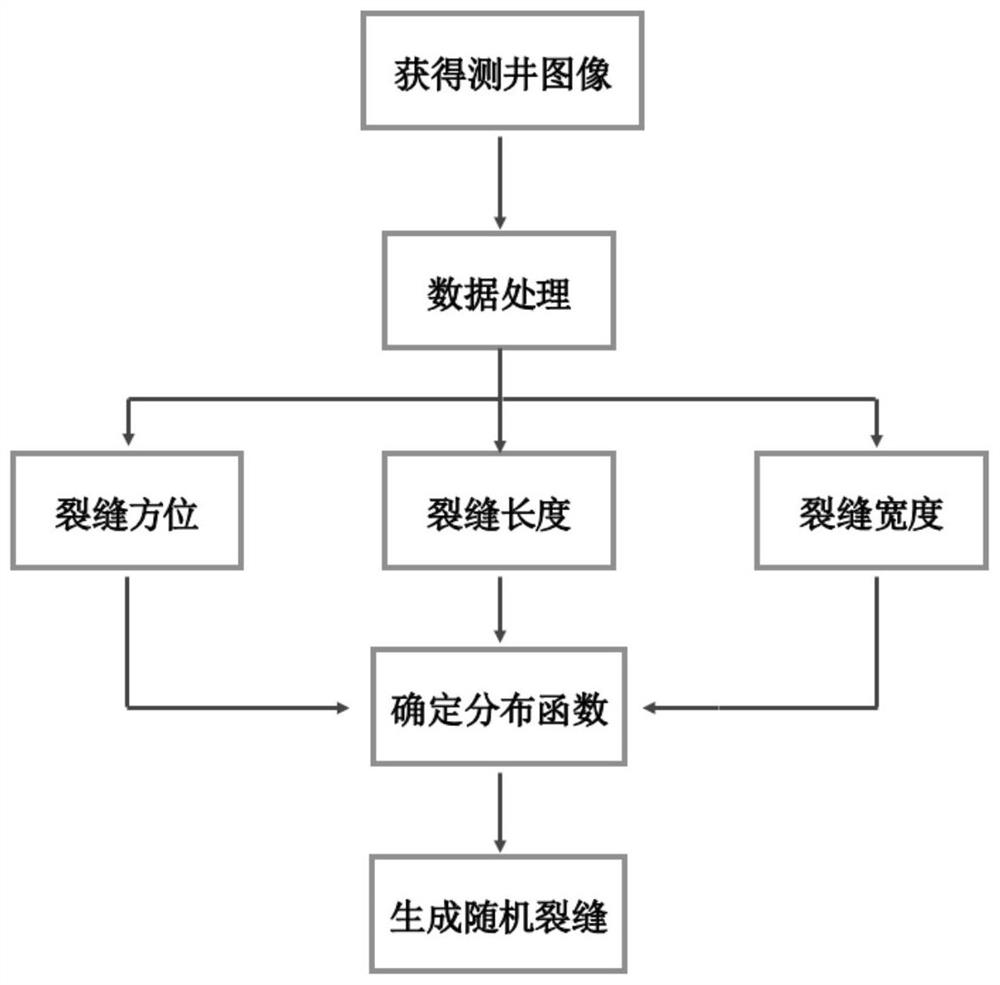

Method used

Image

Examples

Embodiment 1

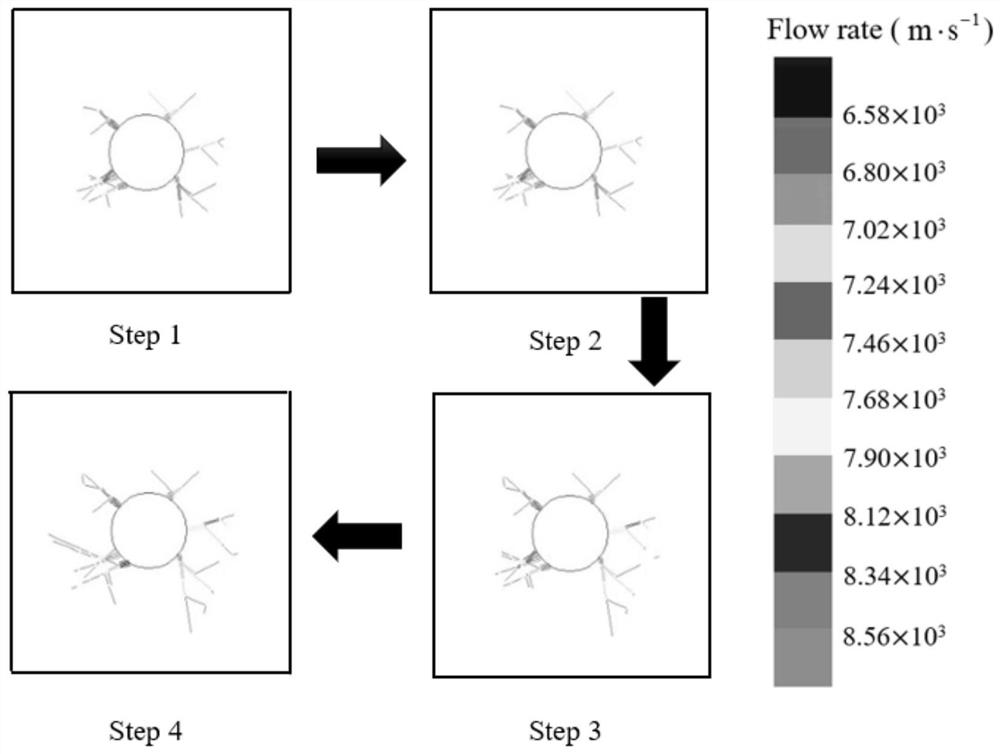

[0080] Mechanical parameters of rock: density is 2.2×10 3 kg / m 3 , the Young's modulus is 15GPa, the shear modulus is 7.72GPa, the internal friction angle is 32 degrees, and the cohesive force is 2MPa. The mechanical parameters of the crack: the shear stiffness is 2000GPa, the normal stiffness is 5000GPa, the joint friction angle is 32 degrees, the tensile strength is 5MPa, and the conductivity of the crack is 83.3Pa -1 ·sec -1 , the aperture at zero normal stress is 2.5×10 -4 m, the residual hydraulic aperture is 1.25×10 -4 m. Parameters of drilling fluid: density 1.1×10 - 3 kg / m 3 , the dynamic viscosity is 1×10 -3 Pa·sec, the cohesion was 0.1 MPa.

[0081] After a finite number of iterations, it can be seen (see image 3 and Figure 4 ), with the increase of the number of operation steps, the fluid flow rate and the fluid pressure in the fracture change dynamically, and the drilling fluid starts to leak along the wall of the fracture.

[0082] for image 3 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com