High-speed electromagnetic valve of high-pressure common-rail oil injector capable of realizing multiple-injection stability

A high-speed solenoid valve and high-pressure common rail technology, applied in fuel injection devices, fuel injection control, electrical control, etc., can solve problems such as rebound and incomplete seating, and achieve improved fuel injection stability, stable closing, and improved seating stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024]下面结合附图举例对本发明做更详细地描述:

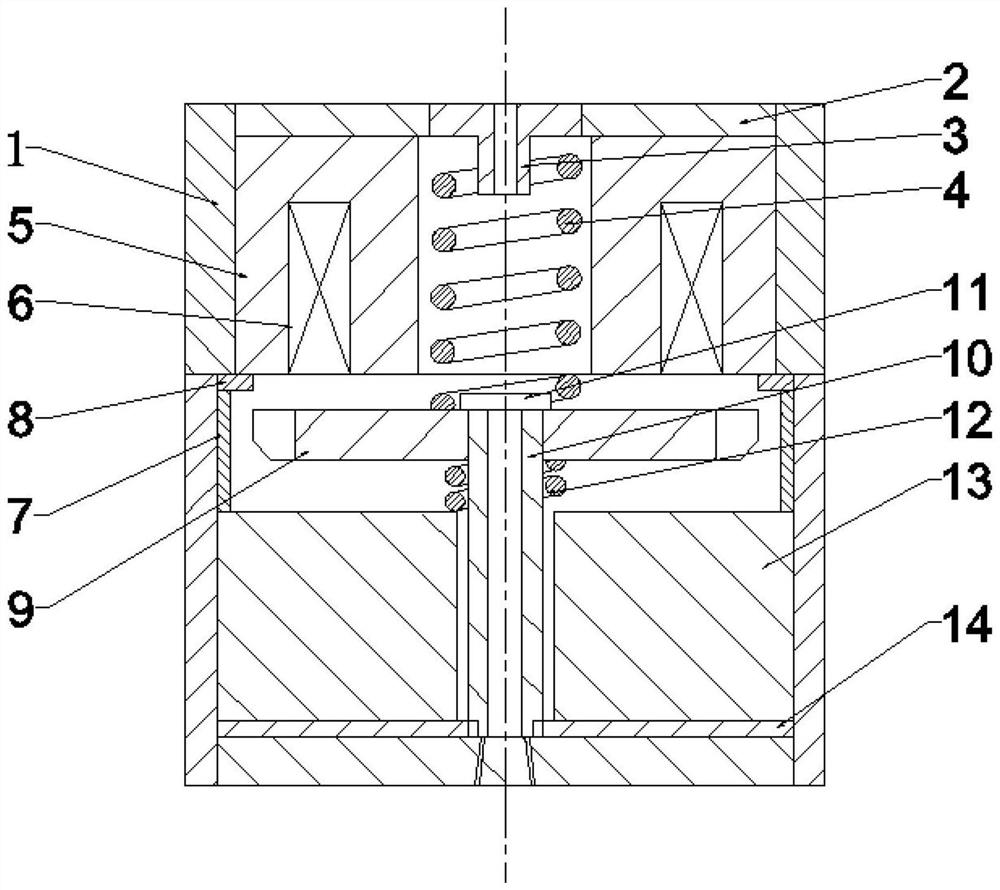

[0025]图1为本发明的结构示意图,包括壳体1、紧固螺母2、电磁阀复位弹簧座3、电磁阀复位弹簧4、铁芯5、线圈6、固定垫片7、缓冲调节垫片8、衔铁9、衔铁阀杆10、阀杆紧固螺母11、缓冲弹簧12、阀座13、缓冲调节环带14,铁芯5凹槽中安装有线圈6,中间通孔里安装有电磁阀复位弹簧4,电磁阀复位弹簧4一端固定在电磁阀复位弹簧座3上,另一端被衔铁9上端顶住,衔铁阀杆10上端与衔铁9通过衔铁紧固螺母11连接,衔铁阀杆10中间开有回油油路,缓冲弹簧12套在衔铁阀杆10上端,置于衔铁9与阀座13中间,衔铁9外缘设有四个弧形切面,所述缓冲调节垫片8设在固定垫片7与铁芯5之间,所述阀杆10下端外缘设有四个垂直切面,所述阀座13开有通孔,通孔内径大于阀杆10外径,阀座13下方设有缓冲调节环带14。缓冲调节垫片8内径小于固定垫片7内径,大于衔铁9外径,与衔铁9外缘形成0.004-0.006mm的上升节流阻尼间隙15,缓冲调节环带14内径大于阀杆10外径,与阀杆10下端外缘形成0.005-0.007mm的落座节流阻尼间隙16。缓冲调节垫片8下端高度低于衔铁9的最大位移处,缓冲调节垫片8下端高度位于衔铁9上升总行程的80%处,缓冲调节环带14上端高度高于阀杆10下端的初始位置,缓冲调节环带14上端高度位于衔铁9落座总行程的80%处。

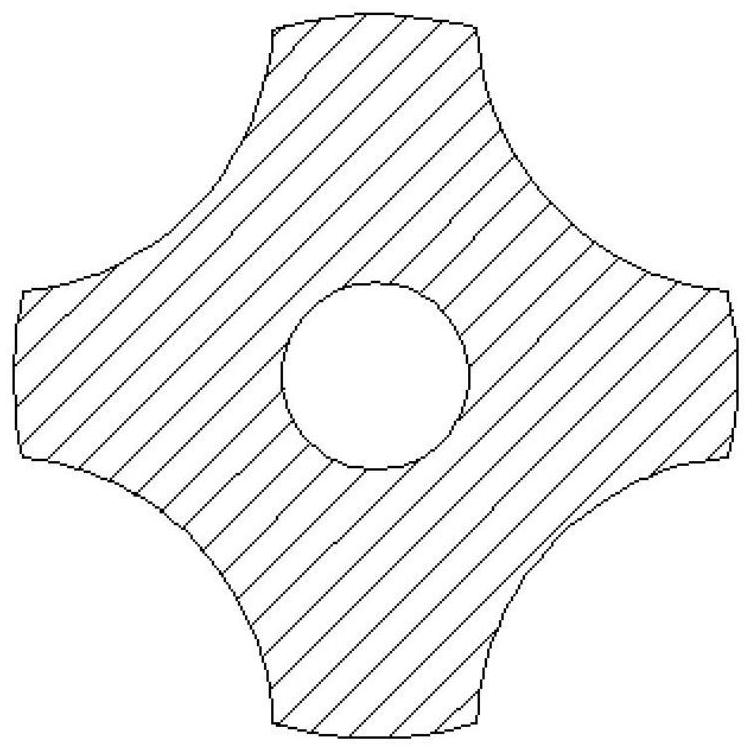

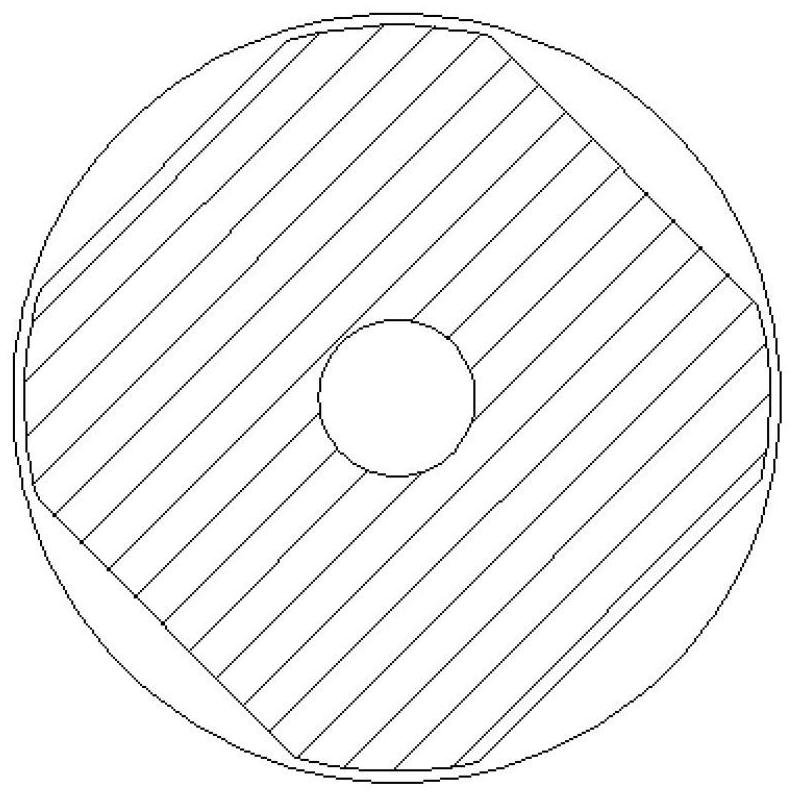

[0026]结合图2-5,本发明的工作原理为,当电磁阀的线圈6不通电时,电磁阀复位弹簧4处于压缩状态,对衔铁9产生一个向下的弹簧力,缓冲弹簧12同样处于压缩状态,对衔铁9产生一个向上的弹簧力,但电磁阀复位弹簧4的弹簧力大于缓冲弹簧12的弹簧力,因此衔铁9在合力的作用下保持在初始位置。当电磁阀的线圈6通电时,同铁芯5和衔铁9形成磁回路,对衔铁9产生电磁力,衔铁9带动衔铁阀杆10一起向上运动,回油油路开启,低压燃油通过衔铁阀杆通孔和衔铁阀杆10外侧泄走。当衔铁9向上运动至与缓冲调节垫片8下端高度齐平时,衔铁9外缘与缓冲调节垫片8产生节流阻尼效应,燃油流通面积骤然缩小至如图4中阴影所示,导致衔铁9上、下两部分的燃油流通面积迅速减小,燃油不能快速通过并受到挤压,这部分燃油压力急剧上升,对衔铁9上升产生阻力,使衔铁9的上升速度下降,降低衔铁9与铁芯5的碰撞,削弱衔铁9碰撞后的反弹,实现高速电磁阀稳定打开。当电磁...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com