Electric valve

A technology of electric valve and valve shaft, applied in the direction of lift valve, valve details, valve device, etc., to reduce leakage, improve durability, and improve seating stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

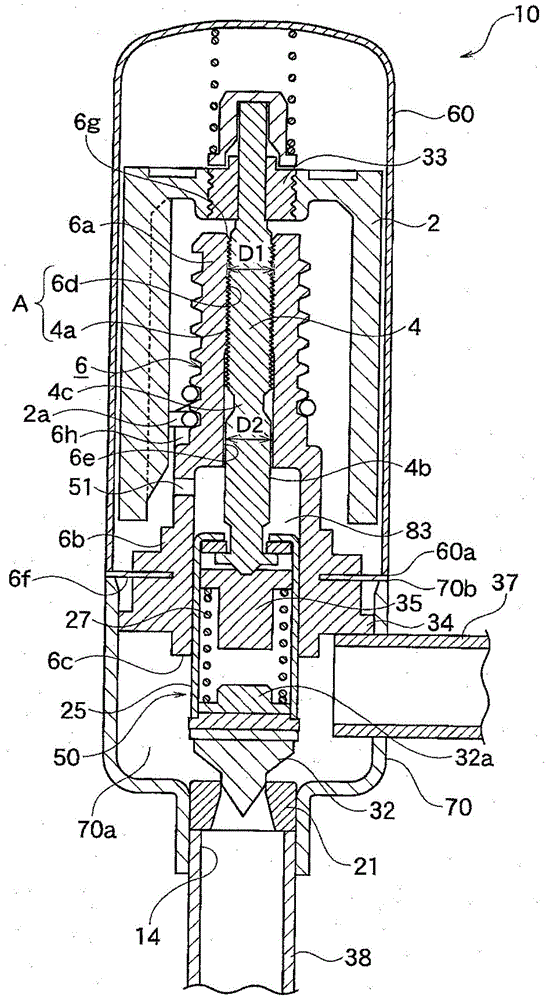

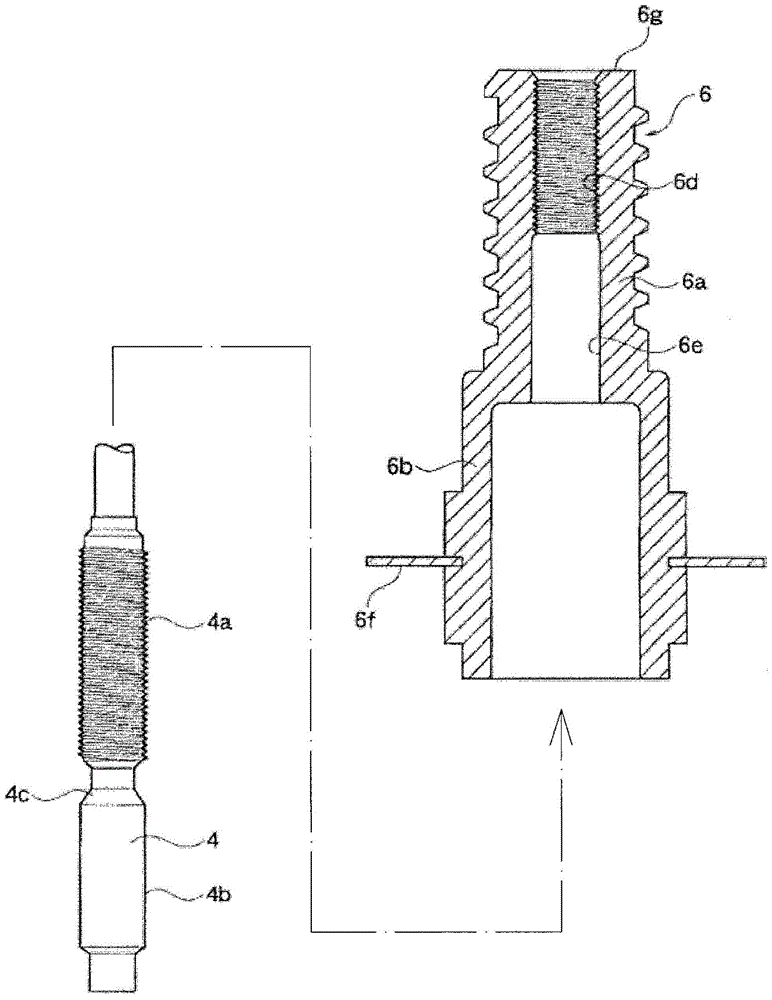

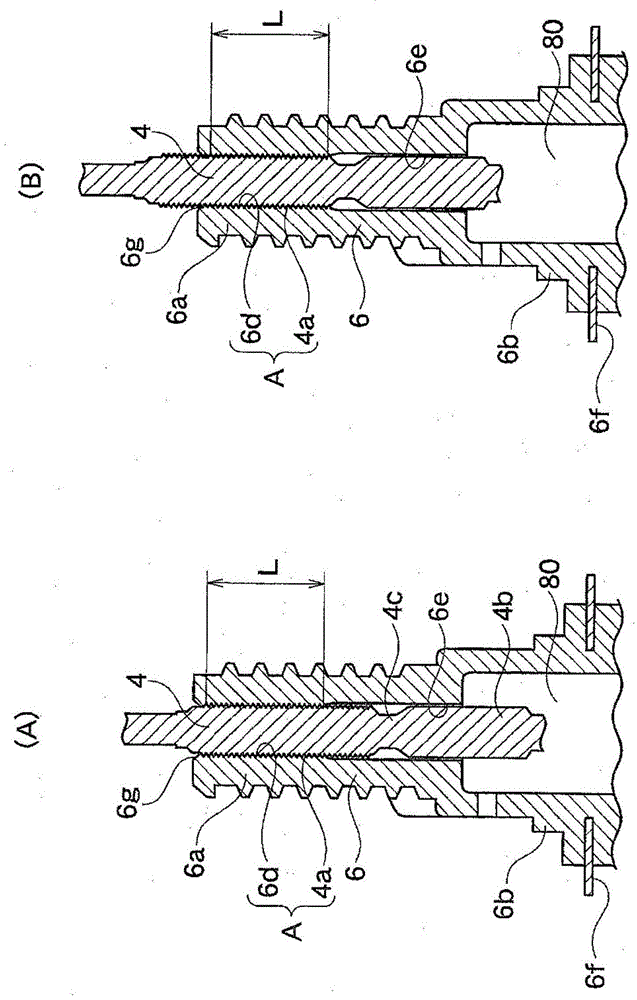

[0063] figure 1 It is a cross-sectional view showing an electric valve according to a preferred embodiment of the present invention, figure 2 yes means figure 1 A schematic diagram of the assembly form of the valve shaft and the valve shaft bracket in the electric valve shown.

[0064] In addition, in this specification, "upper" or "lower" means figure 1 specified by the state.

[0065] In this electric valve 10 , a valve chamber forming member 70 is integrally connected by welding to the lower end portion on the opening side of a cylindrical cup-shaped case 60 made of a non-magnetic material.

[0066] In the valve chamber 70 a of the valve chamber forming member 70 , the first joint 38 is connected downward (axially), the second joint 37 is connected to the side, and the input and output ports of the valve chamber forming member 70 connected to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com