Cutting inserts and indexable insert cutting tools

A technology of cutting inserts and inserts, used in milling cutting inserts, manufacturing tools, milling cutters, etc., can solve problems such as wedge angle or clearance angle limitation, and achieve the effect of improving seating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

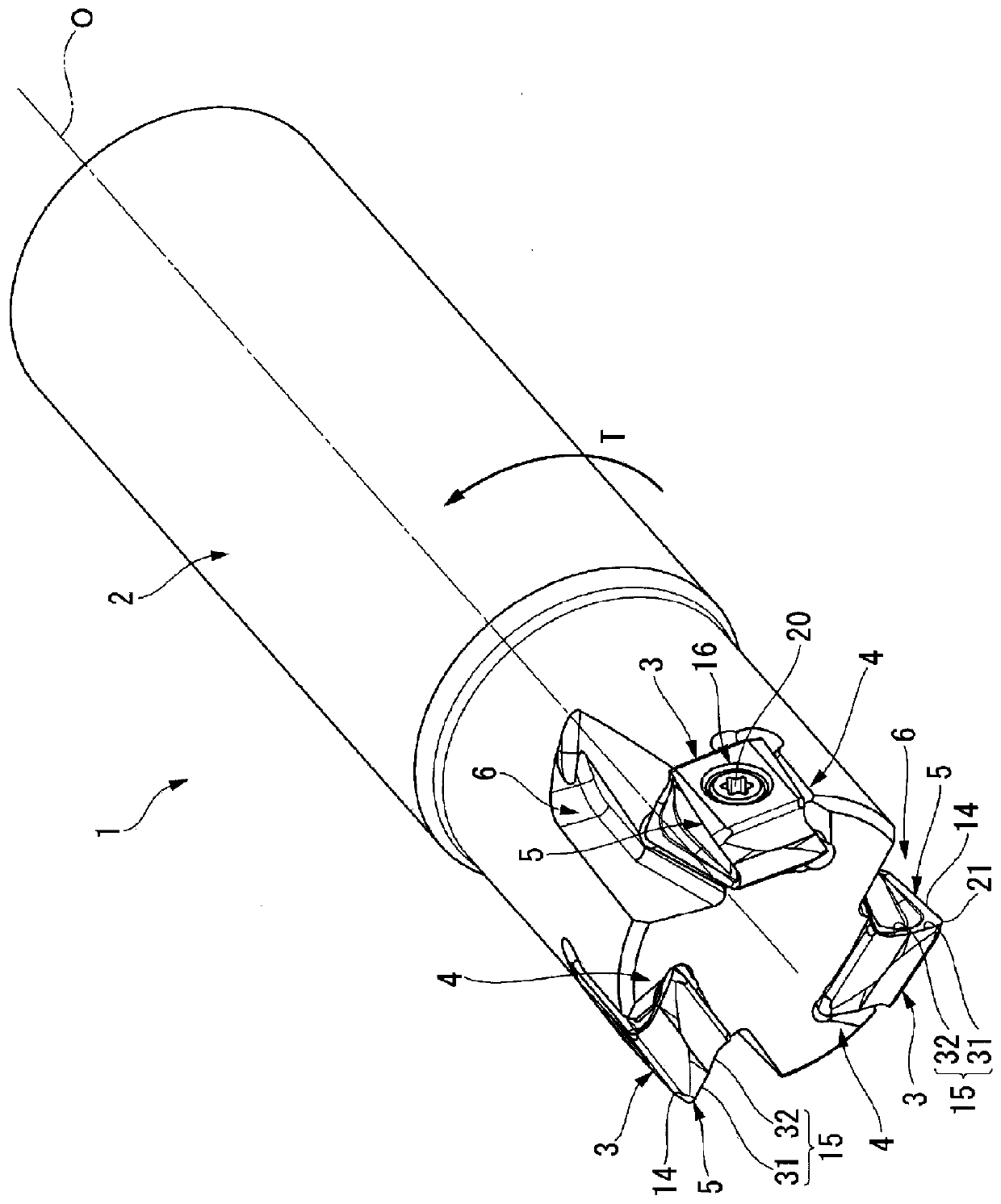

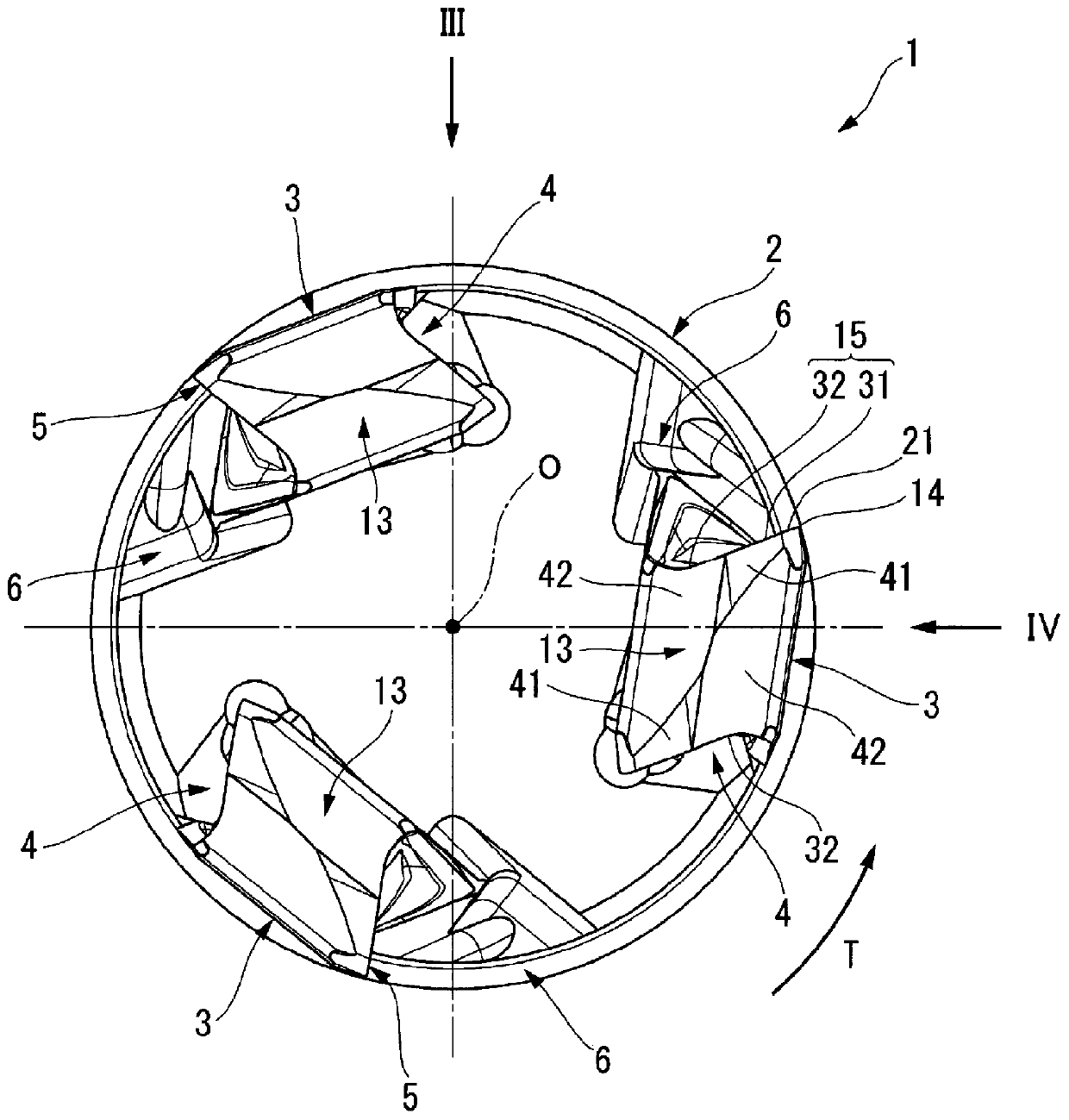

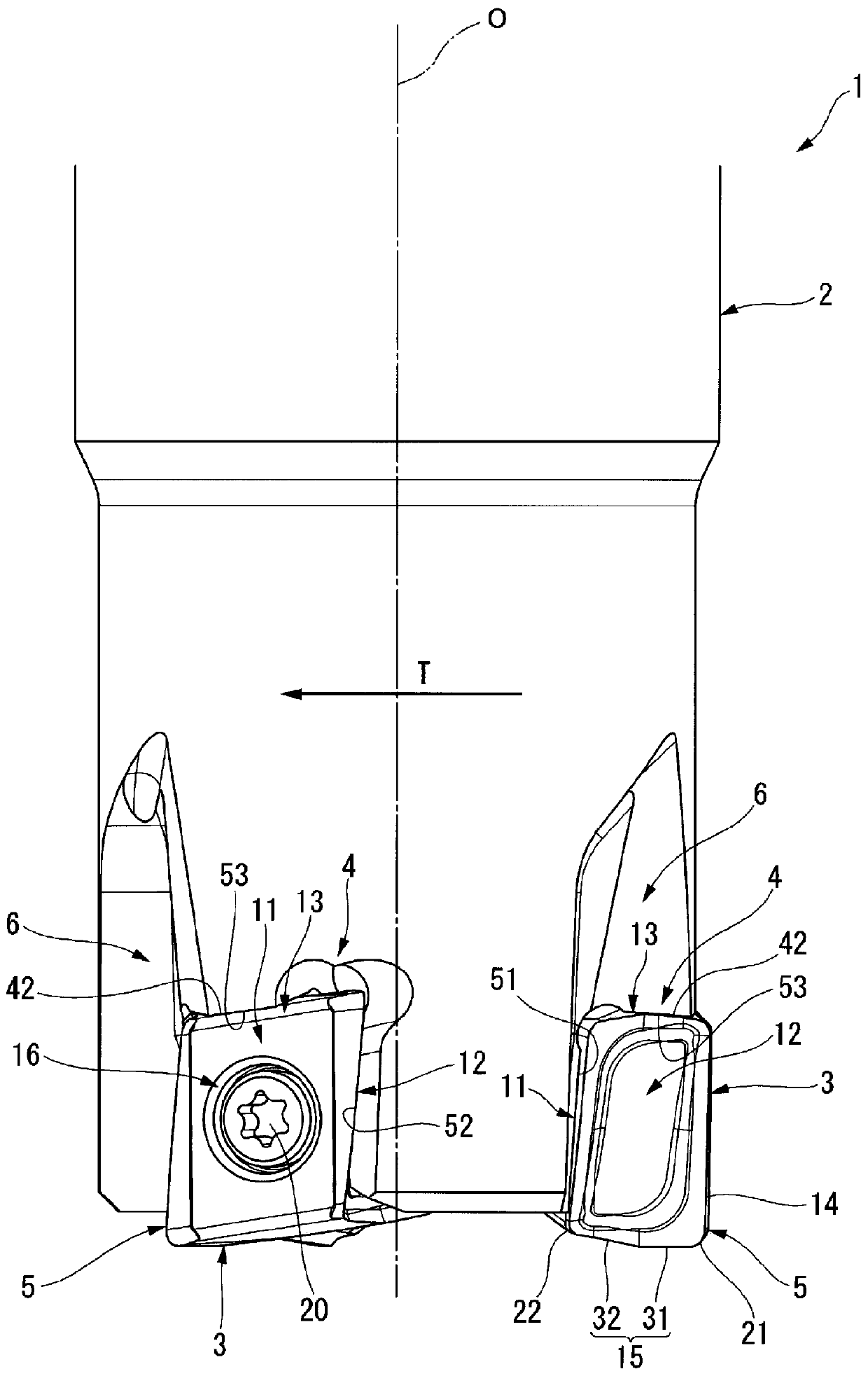

[0084] Below, refer to Figure 1 to Figure 16 , the indexable insert type cutting tool 1 and the cutting insert 3 according to the first embodiment will be described.

[0085] 〔Outline structure of indexable insert cutting tool〕

[0086] Such as Figure 1 to Figure 4 As shown, the indexable insert cutting tool 1 of this embodiment includes a tool body 2 formed of steel or the like, and a cutting insert 3 formed of a hard material such as cemented carbide. A concave insert mounting seat 4 is formed on the outer peripheral portion of the front end of the tool body 2 that rotates around the tool axis O. As shown in FIG. A cutting insert 3 having a cutting edge 5 is detachably attached to the insert mounting seat 4 .

[0087] Such as Figure 5 to Figure 8 As shown, the cutting insert 3 is a so-called vertical double-sided cutting insert. The cutting insert 3 has a rectangular plate shape, and is formed in a front-back and reverse-symmetric shape. The cutting insert 3 include...

no. 2 Embodiment approach >

[0205] Next, refer to Figure 17 and Figure 18 , the cutting insert 30 of the indexable insert cutting tool according to the second embodiment will be described.

[0206] Note that detailed descriptions of components that are the same as those in the aforementioned embodiment will be omitted, and only differences will be described below.

[0207] [Differences from the previous embodiment]

[0208] The indexable insert type cutting tool of this embodiment is the same as the tool body 2 of the indexable insert type cutting tool 1 described in the above-mentioned embodiment, but the cutting insert 30 is different. Specifically, in the cutting insert 30, the structure of the short side surface 13 is mainly different.

[0209] Such as Figure 17 and Figure 18 As shown, in the cutting insert 30 of the present embodiment, a pair of first minor cutting edges 31 extending from both end edges of the short side surface 13 in the insert long side axis C2 direction extend toward opp...

no. 3 Embodiment approach >

[0219] The cutting insert 130 of the indexable insert cutting tool according to the third embodiment of the present invention will be described. Figure 20 It is a cross-sectional view of an indexable insert tool to which the cutting insert 130 according to the third embodiment is mounted. and, Figure 21 yes Figure 20 Enlarged view of region XXI of .

[0220] Note that detailed descriptions of components that are the same as those in the aforementioned embodiment will be omitted, and only differences will be described below.

[0221]The indexable insert type cutting tool of this embodiment is the same as the tool body 2 of the indexable insert type cutting tool 1 described in the above-mentioned embodiment, but the cutting insert 130 is different. Specifically, the structure of the mounting hole 116 of the cutting insert 130 is different.

[0222] The cutting insert 130 of this embodiment is provided with the mounting hole 116 similarly to the first embodiment. The moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com