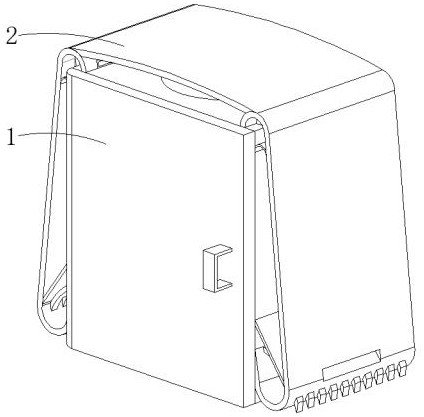

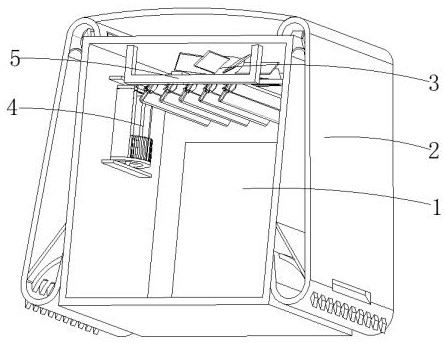

Hydraulic lubrication control cabinet

A hydraulic lubrication and control cabinet technology, applied in the field of control cabinets, can solve problems such as gravel collision, damage to the structure of the hydraulic lubrication control cabinet, and affect the working stability of the hydraulic lubrication control cabinet, so as to improve stability and speed up air circulation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

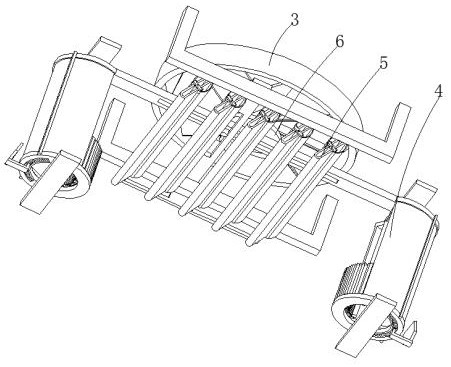

[0029] During the use of the control cabinet main body 1, the cooling fan group 3 will dissipate heat to the electrical components in the control cabinet main body 1. The back-shaped plate 46 cooperates so that the convex column of the convex post plate 46 drives the Y-shaped interference rod 45 to slide back and forth along the fixed frame 41 through the back-shaped plate 6, and the Y-shaped interference rod 45 pushes the circular V-groove dust-proof net 43 along the circle. The rod 42 rotates, thereby achieving the purpose of the dynamic rotation of the circular V-groove dust-proof net 43, thereby avoiding the problem that dust adheres to it and affects its heat dissipation effect; at the same time, through the setting of the cleaning scraper 48, the cleaning scraper 48 scrape off the dust attached to the outer wall of the circular V-groove dust-proof net 43, thereby achieving the purpose of cleaning the outer wall of the circular V-groove dust-proof net 43.

[0030] At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com