Automatic welding equipment for header welding

An automatic welding and header technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that it is difficult to ensure that the welding gun is caught in time, slow down the work efficiency of workers, and troublesome disassembly, etc., to improve Effects of practicality and creativity, increased practicality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

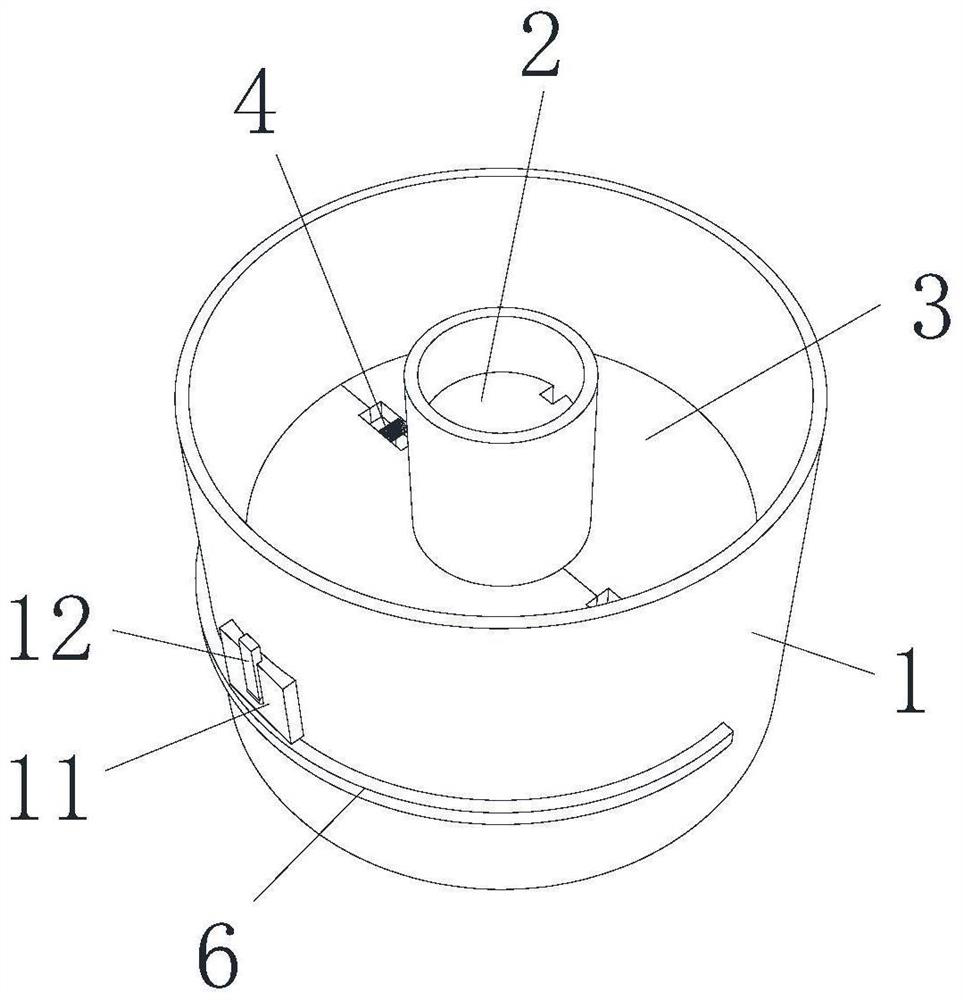

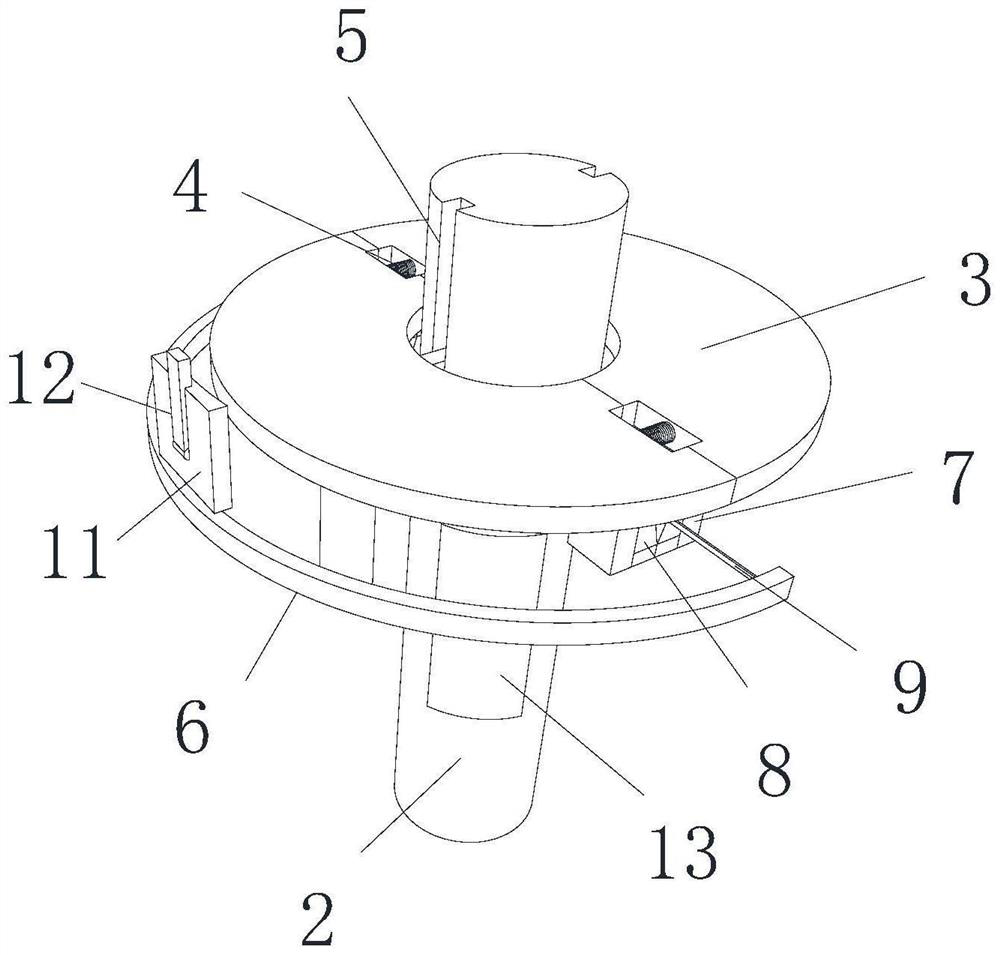

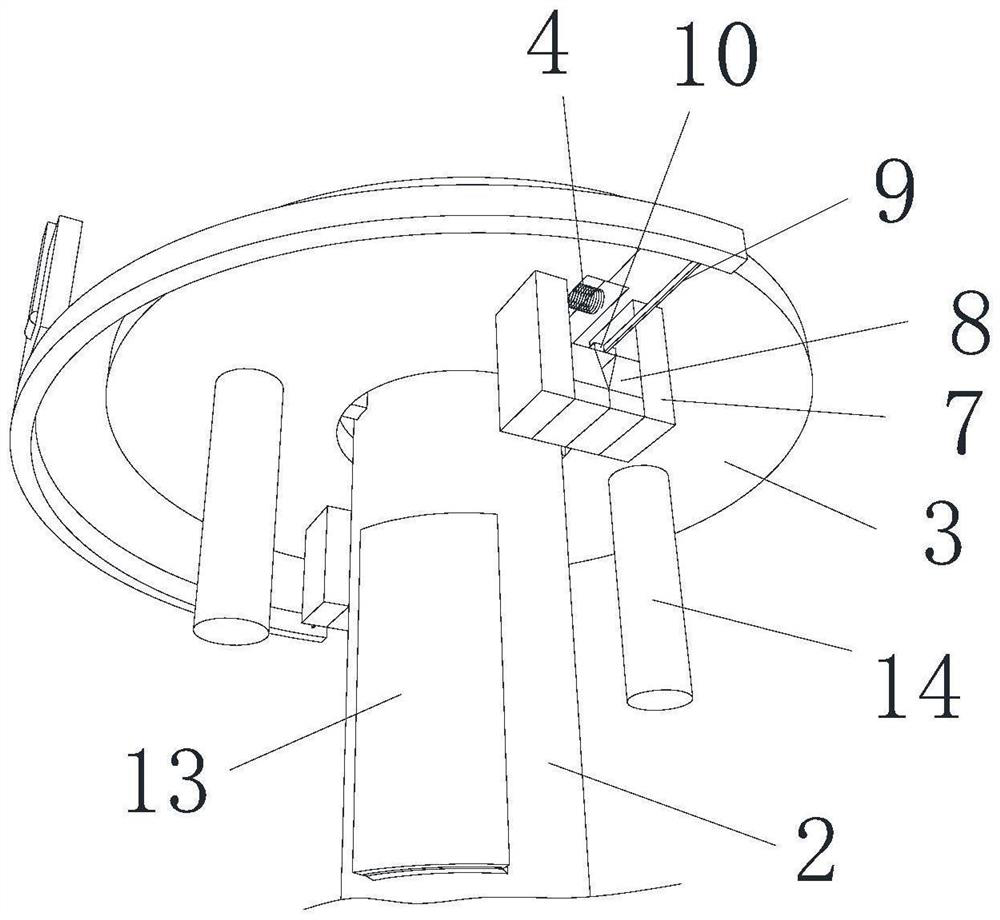

[0030] Embodiment 1: A kind of automatic welding equipment for header welding, such as Figure 1-Figure 3As shown, including a manipulator 1, the manipulator 1 is a hollow circular ring, the inner cavity of the manipulator 1 is inserted with a welding gun 2, the hollow part of the manipulator 1 is provided with a fixing device, and the fixing device includes a fixed splint 3, and the number of the fixed splints 3 is Two, the two fixed splints 3 are symmetrically arranged in the manipulator 1, and the two fixed splints 3 form a circular ring that matches the shape of the welding gun 2, and the bottoms of the two fixed splints 3 are fixedly installed with support columns for support. 14. The other end of the support column 14 is in contact with the bottom surface of the inner cavity of the manipulator 1. The side wall of the manipulator 1 is provided with a disengagement device, and the disengagement device includes a deceleration plate 13 for deceleration. It is located at the ...

Embodiment 2

[0032] Embodiment 2: A kind of automatic welding equipment for header welding, such as Figure 1-Figure 3 As shown, including a manipulator 1, the manipulator 1 is a hollow circular ring, the inner cavity of the manipulator 1 is inserted with a welding gun 2, the hollow part of the manipulator 1 is provided with a fixing device, and the fixing device includes a fixed splint 3, and the number of the fixed splints 3 is Two, the two fixed splints 3 are symmetrically arranged in the manipulator 1, and the two fixed splints 3 form a circular ring that matches the shape of the welding gun 2, and the bottoms of the two fixed splints 3 are fixedly installed with support columns for support. 14. The other end of the support column 14 is in contact with the bottom surface of the inner cavity of the manipulator 1. The side wall of the manipulator 1 is provided with a disengagement device, and the disengagement device includes a deceleration plate 13 for deceleration. It is located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com