Steel plate grinding device for automobile machining and using method of steel plate grinding device

A steel plate and automobile technology, which is applied in the field of steel plate grinding devices for automobile processing, can solve the problems of severe vibration and operator injury, and achieve the effects of improving independence, comfort and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

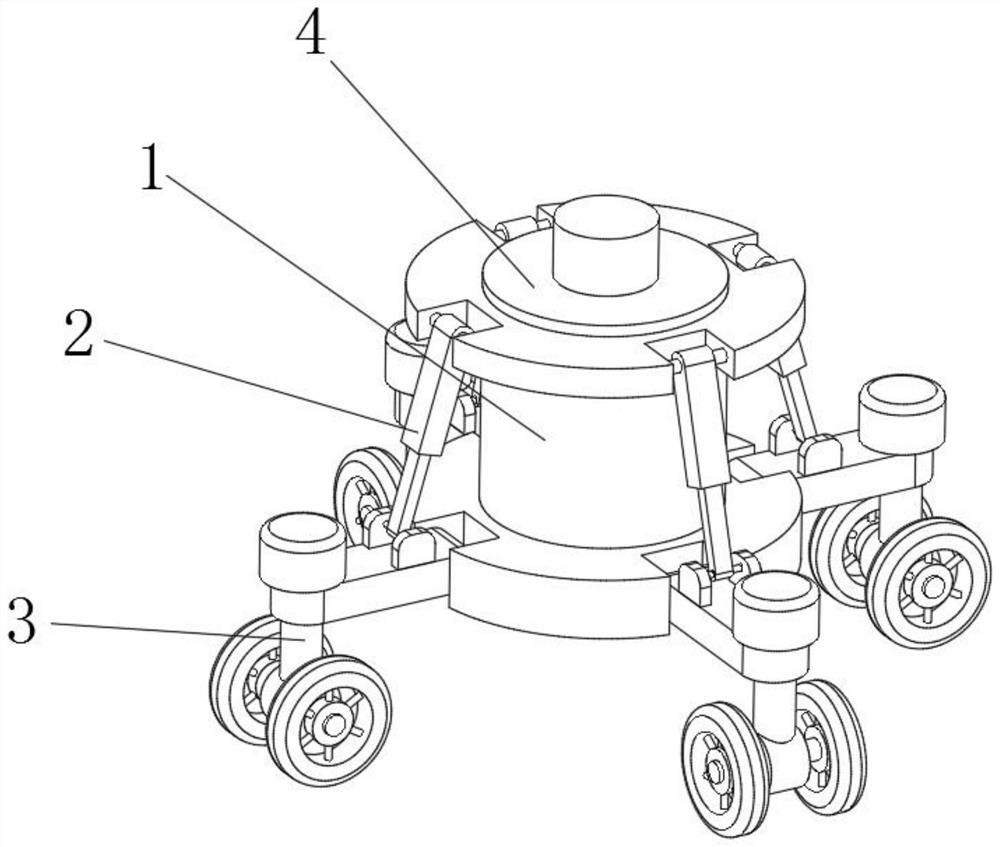

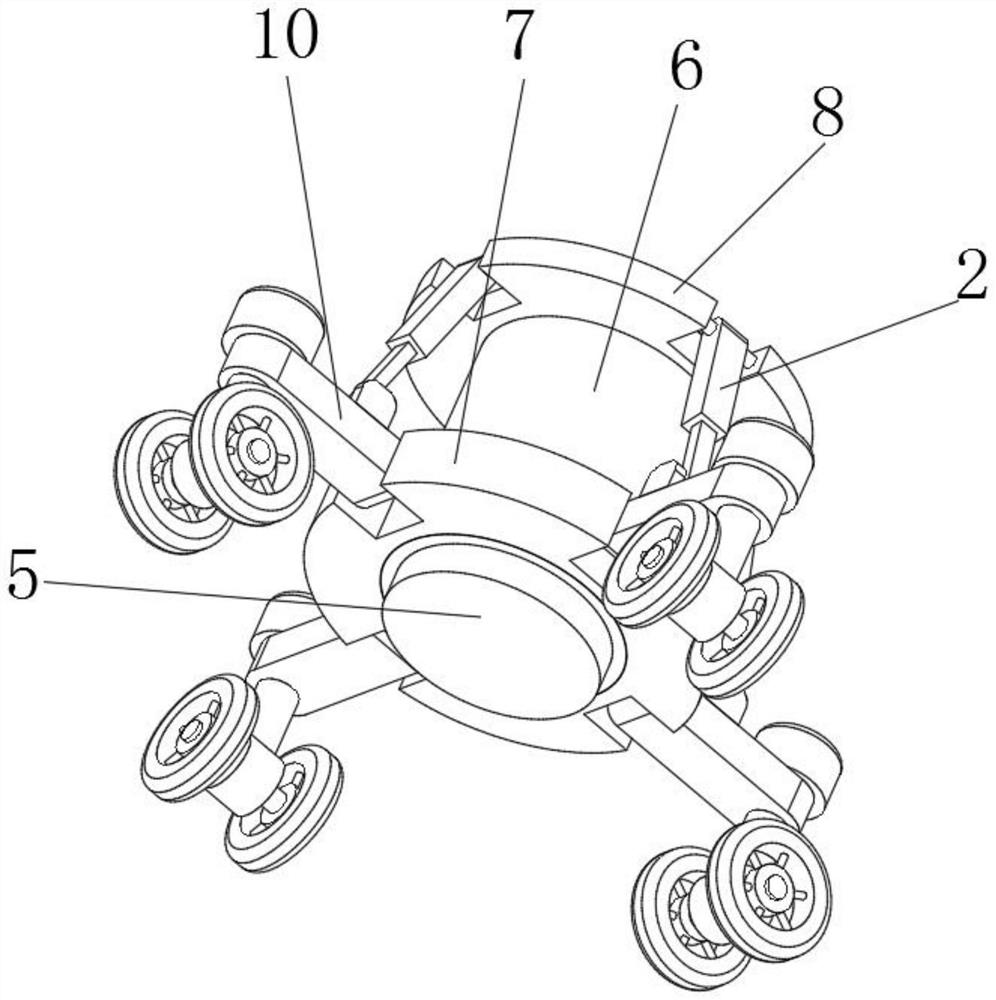

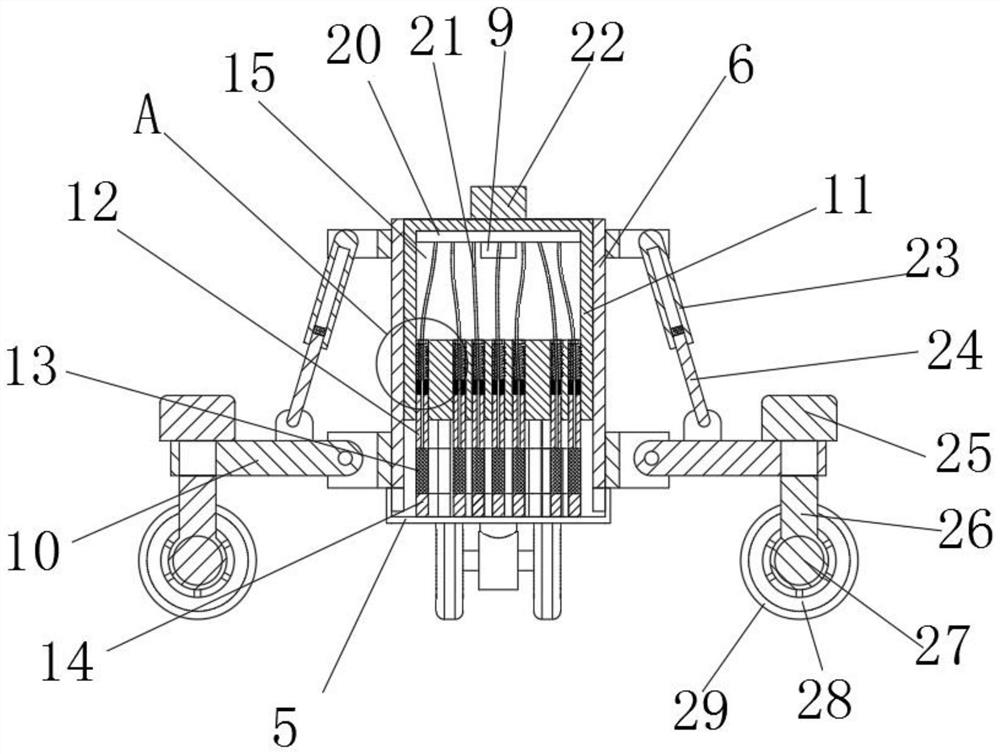

[0036] see Figure 1-5 , a steel plate grinding device for automobile processing, comprising a body 1, the bottom of the body 1 is provided with a plurality of adsorption and moving mechanisms 3, and a support mechanism 2 is provided between the plurality of adsorption and moving mechanisms 3 and the upper end of the body 1, and the bottom surface of the body 1 is provided. A grinding cloth 5 is fixedly installed in the center, the adsorption and moving mechanism 3 is set against the surface of the steel plate member, the body 1 presses the grinding cloth 5 against the surface of the steel plate member, and a vibration grinding mechanism 4 is arranged in the body 1. The upper ends of the cloth 5 abut against each other, and high-frequency vibration is generated on the contact surface of the steel plate member through the polishing cloth 5 .

[0037] In this embodiment, the polishing cloth 5 adopts the ultra-precision coating technology, and the selected micron or nano-scale ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com