Black master batch and preparation method thereof

A black masterbatch, a special technology, applied in the field of plastic modification, can solve the problems of decreased customer acceptance, reduced product performance, product decomposition, etc., to improve product quality, increase output and production capacity, and shorten uniformity and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

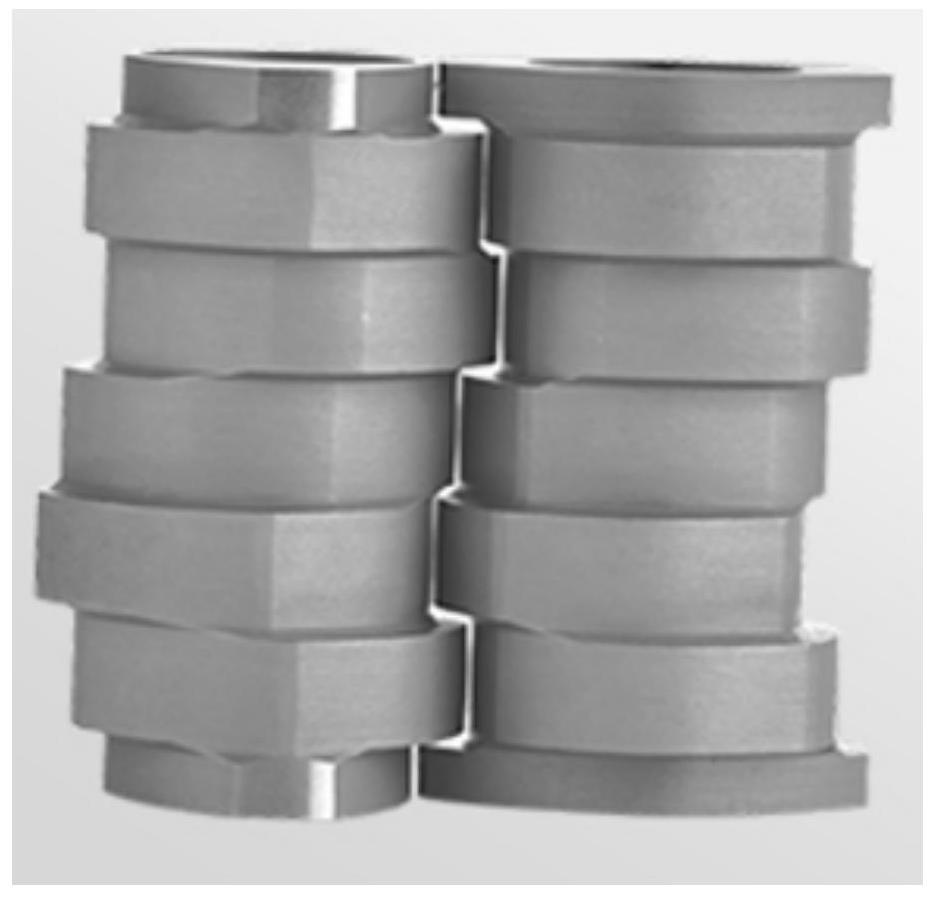

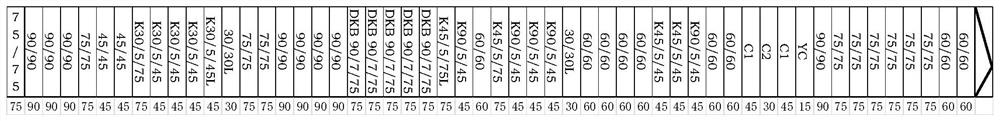

Image

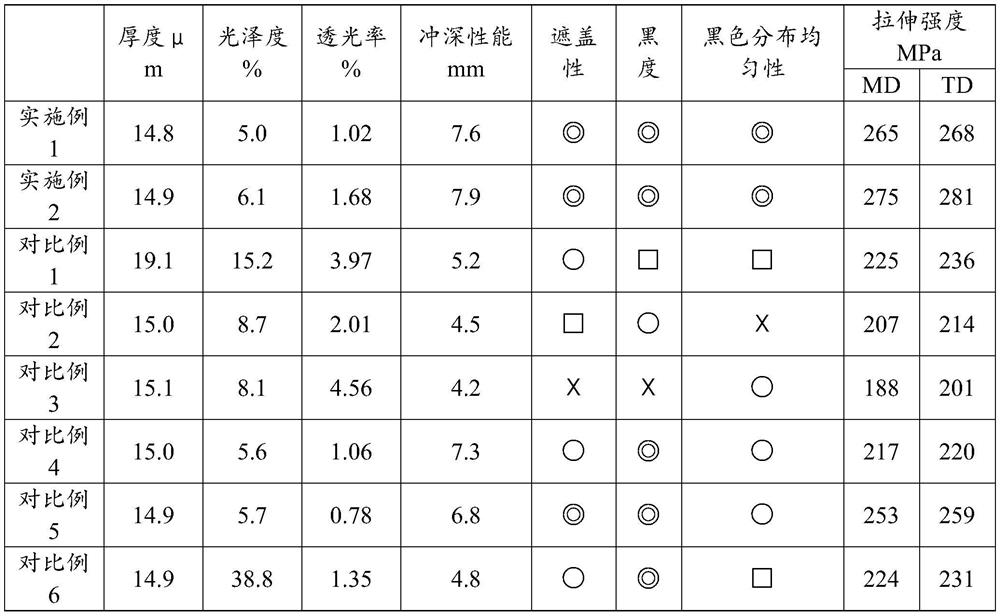

Examples

Embodiment 1

[0054] The matte black polyamide film for a lithium ion battery in this embodiment includes a three-layer film structure, which are a matte black polyamide upper surface layer, a polyamide middle layer and a black polyamide lower surface layer in order from top to bottom. In parts by mass, the upper surface layer includes 5 parts of black masterbatch, 10 parts of toughening agent, 5 parts of matte agent, 2 parts of additives, and 78 parts of polyamide; the middle layer is 100 parts of polyamide amide; the lower layer includes 5 parts of black masterbatch, 10 parts of toughener, 2 parts of additives, and 83 parts of polyamide.

[0055] In this embodiment, the additive is selected from a mixture of three kinds of lubricants, opening agents and antioxidants in a ratio of 1:2:1; the lubricant is selected from erucamide; the antioxidant is selected from antioxidant 1098, antioxidant A mixture of three kinds of oxygen agent 168 and antioxidant SEED in a ratio of 2:1:2; the opening a...

Embodiment 2

[0075] The matte black polyamide film for lithium ion batteries in this embodiment has a three-layer film structure, and from top to bottom are the matte black polyamide upper surface layer, the polyamide middle layer and the black polyamide lower layer in order. In parts by mass, the upper surface layer includes 3 parts of black masterbatch, 10 parts of toughening agent, 3 parts of matte agent, 2 parts of additive, 82 parts of polyamide; the middle layer is 100 parts of polyamide amide; the lower layer includes 3 parts of black masterbatch, 10 parts of toughener, 2 parts of additives, 85 parts of polyamide.

[0076] In this embodiment, the additive is selected from a mixture of three kinds of lubricants, opening agents and antioxidants in a ratio of 1:2:1; the lubricant is selected from erucamide; the antioxidant is selected from antioxidant 1098, antioxidant A mixture of three kinds of oxygen agent 168 and antioxidant SEED in a ratio of 2:1:2; the opening agent is selected f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com