Anthocyanin-rich grape Ale beer and brewing method thereof

A grape ale and anthocyanin technology, applied in the field of beer brewing, can solve the problems of limited brewing technology and fruit raw material cost, and achieve the effects of increasing layering and complexity, novel style, and a wide range of drinkable people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

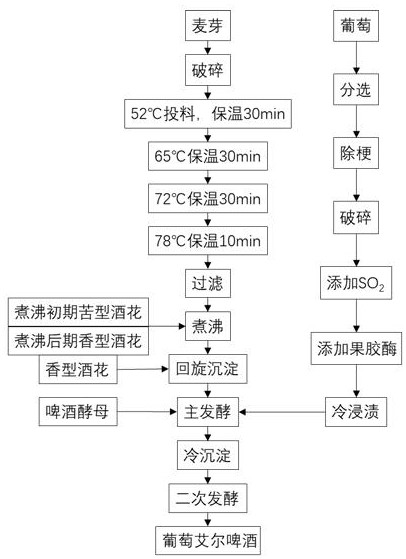

Image

Examples

Embodiment 1

[0026] An anthocyanin-rich grape ale includes the following ingredients: 43.4 parts of pale ale malt, 44 parts of pilsner malt, 10 parts of caramel pilsner malt, and 8 parts of pale crystal malt.

[0027] A kind of brewing method steps of grape ale beer rich in anthocyanins are:

[0028] (1) The raw material and water are incubated at 52°C for 30min, then heated to 65°C for 30min, then heated to 72°C and incubated for 20min, finally heated to 78°C and incubated for 10min for saccharification, after the saccharification is completed, filter and boil, after boiling, 20~ Add 9% of the total mass of hops for 30min, add 45.5% of the total mass of hops 15min before the end of boiling, and then cyclone precipitation for 20min, add 45.5% of the hops of the total mass of flavor hops during the cyclotron precipitation for 10min; the sugar content is 15° P's original wort;

[0029] (2) inserting brewer's yeast into the original wort obtained in step (1), and fermenting for 3 days at 18°...

Embodiment 2

[0036] An anthocyanin-rich grape ale includes the following ingredients: 40 parts pale ale malt, 40 parts pilsner malt, 5 parts caramel pilsner malt, and 5 parts pale crystal malt.

[0037] A kind of brewing method steps of grape ale beer rich in anthocyanins are:

[0038] (1) The raw material and water were incubated at 52°C for 26min, then heated to 63°C for 30min, then heated to 70°C for 18min, finally heated to 78°C and incubated for 10min for saccharification, after the saccharification was completed, filter and boil, add 30min after boiling Bitter hops with a total mass of 9% of the total hops, add 45.5% of the total hop mass of aroma hops 15min before the end of boiling, and then cyclone precipitation for 20min, add 45.5% of the total hop mass of flavor hops during the cyclotron precipitation for 10min, to obtain a sugar content of 13. °P raw wort;

[0039] (2) inserting brewer's yeast into the original wort obtained in step (1), and fermenting for 3 days at 19°C;

[...

Embodiment 3

[0046] An anthocyanin-rich grape ale includes the following ingredients: 45 parts pale ale malt, 45 parts pilsner malt, 10 parts caramel pilsner malt, and 10 parts pale crystal malt.

[0047] A kind of brewing method steps of grape ale beer rich in anthocyanins are:

[0048] (1) The raw material and water were kept at 50°C for 25min, then heated to 63°C for 23min, then heated to 72°C for 17min, finally heated to 78°C and kept for 10min to perform saccharification, after the saccharification was completed, filter and boil, add 30min after boiling Bitter hops with a total mass of 9% of the total hops, add 45.5% of the total hop mass of aroma hops 15min before the end of boiling, and then cyclone precipitation for 20min, add 45.5% of the total hop mass of the aroma hops during the cyclotron precipitation for 10min; the obtained sugar content is 15 °P raw wort;

[0049] (2) inserting brewer's yeast into the original wort prepared in step (1), and fermenting for 2 to 3 days at 18 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap