Splicing type anti-collision barrel

An anti-collision and connecting block technology, which is applied to roads, buildings, road safety devices, etc., can solve the problems that the anti-collision bucket cannot be quickly spliced, and the anti-collision bucket cannot be used for iron towers, etc., and achieves rapid splicing and stable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

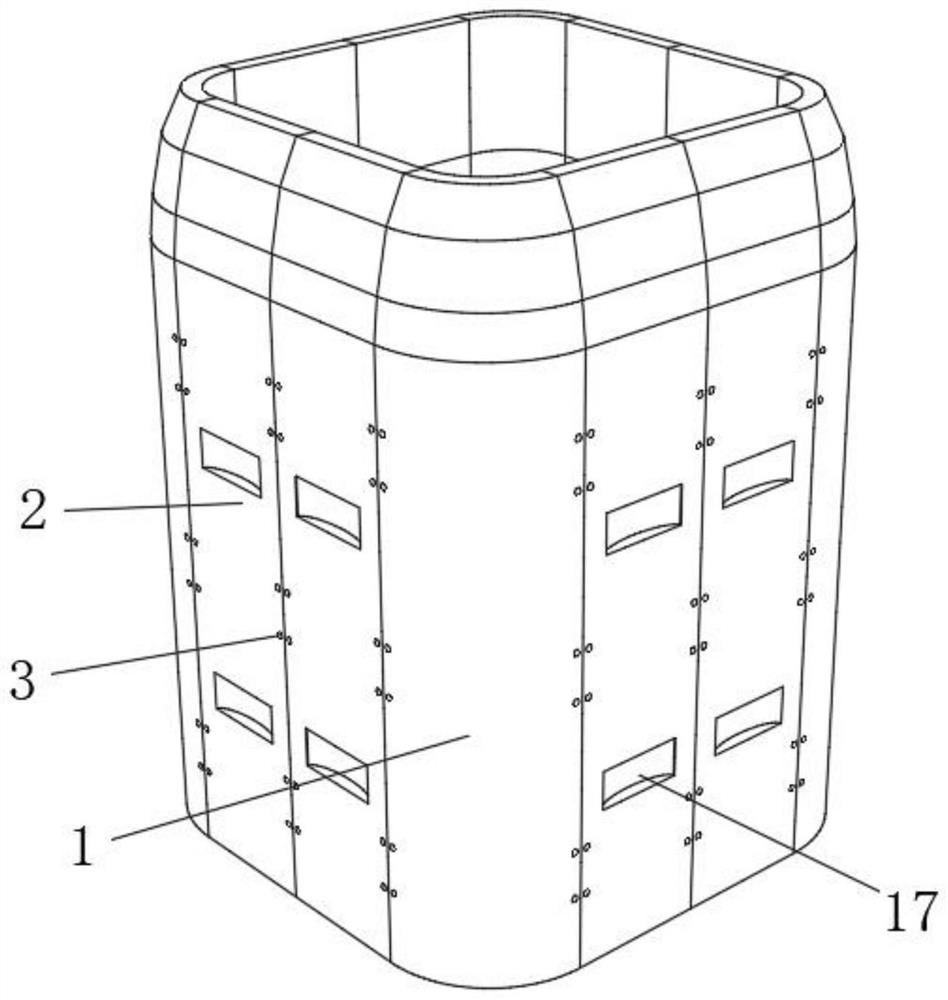

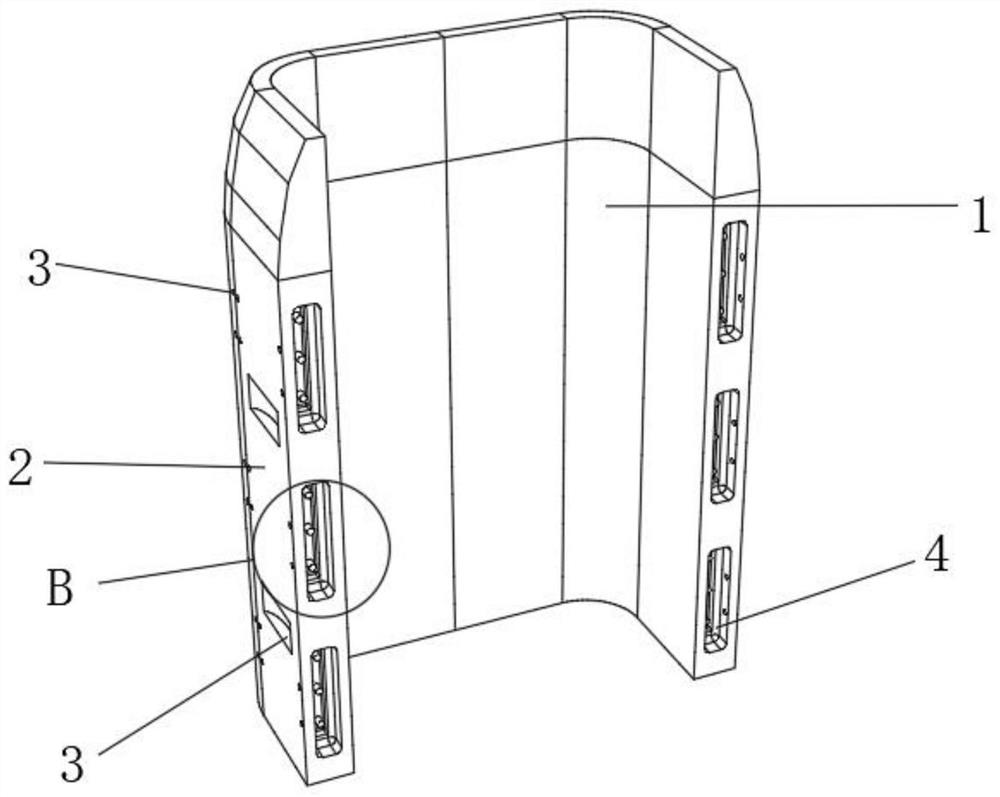

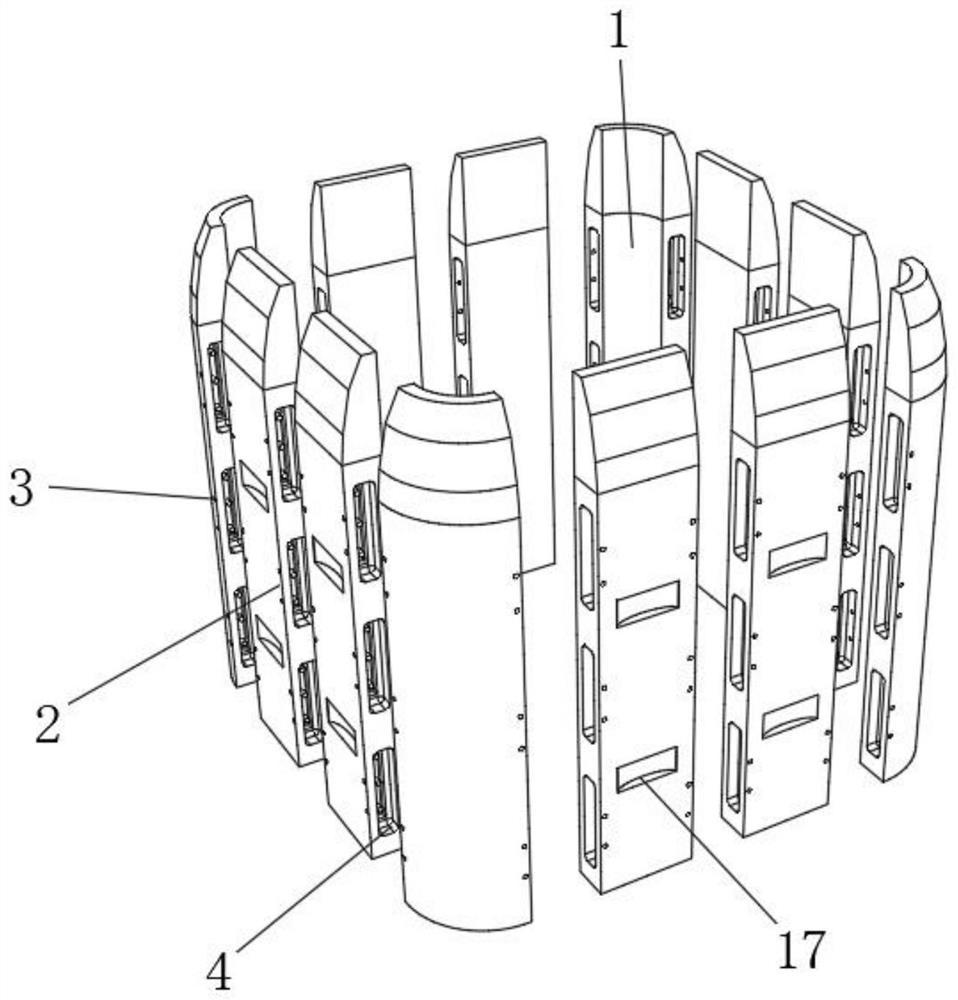

[0026] like Figure 1-6 As shown, the embodiment of the present invention provides a spliced anti-collision bucket, including an anti-collision gusset 1 and an anti-collision plate 2, the anti-collision gusset 1 is designed with an outer circle and an inner square, and between the anti-collision gusset 1 They are all connected by the connecting block 5, and the anti-collision bag corner plate 1 and the anti-collision plate 2 are connected by the connecting block 5. The connecting block 5 is arranged inside the connecting port 4, and the connecting port 4 is all set on the anti-collision bag corner plate 1. The connecting end with the anti-collision plate 2, the inner and outer sides of the connection port 4 are provided with evenly distributed card slots 13, and the outer sides of the anti-collision plate 2 are provided with evenly distributed climbing grooves 17. The anti-collision bucket is set to be square, and through the cooperation of the connection block 5 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com