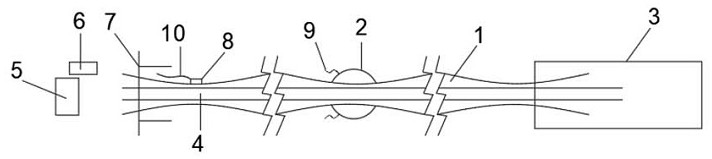

Anchor cable recovery device and method based on hot melting structure

A technology for recovering devices and anchor cables, which is applied in foundation structure testing, foundation structure engineering, earthwork drilling and mining, etc. It can solve the problems of inability to effectively monitor real-time changes in anchoring force, poor application effect of hot-melt anchorage, and increased anchorage. problems such as anchoring force, to achieve the effect of rapid maintenance and replacement, low production cost, and enhanced anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

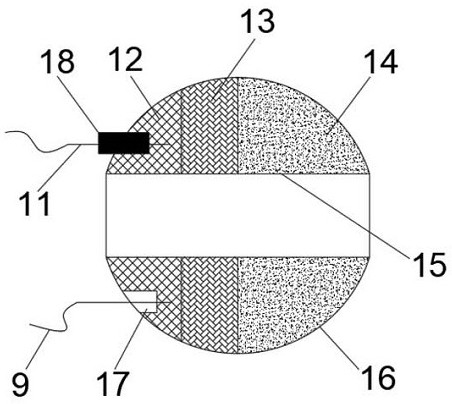

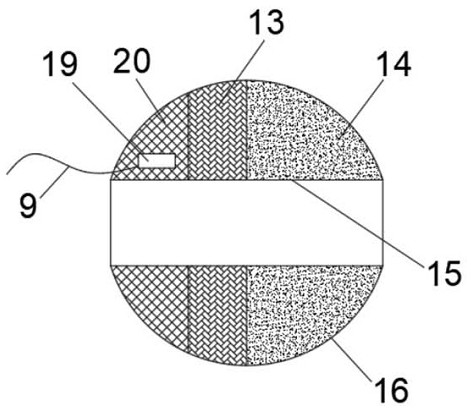

[0046] According to a preferred embodiment, with the constant attenuation of the anchoring force of the anchor cable bundle 1, the risks corresponding to different anchoring force variation intervals are different, and the corresponding grouting amounts are also different. Preferably, for different anchoring force variation intervals, the sampling periods of the strain sensors 8 are different, and the corresponding preset strain amplitudes are also different. Specifically, the engineer can set different anchoring force variation intervals for the anchor cable bundle 1 according to the requirements of the anchoring project, and set different preset strain amplitudes for each anchoring force variation interval, so that with the change of the anchoring force, The monitoring frequency of the anchor cable bundle 1 by the strain sensor 8 is adjusted in time, thereby improving the timeliness of monitoring the anchoring force of the anchor cable bundle 1 .

[0047] In particular, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com