Wind tunnel testing device for wind load of arc-shaped conductor

A technology of arc-shaped wire and testing device, which is applied in the direction of measuring device, machine/structural component testing, aerodynamic test, etc. Height and other issues, to meet different test requirements, the effect of precise angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

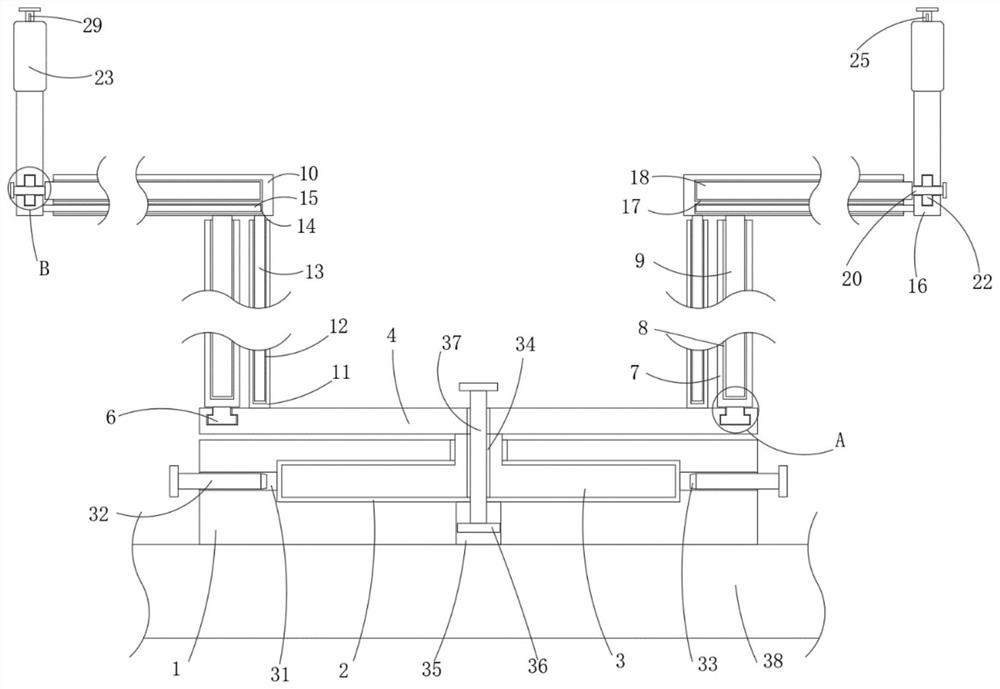

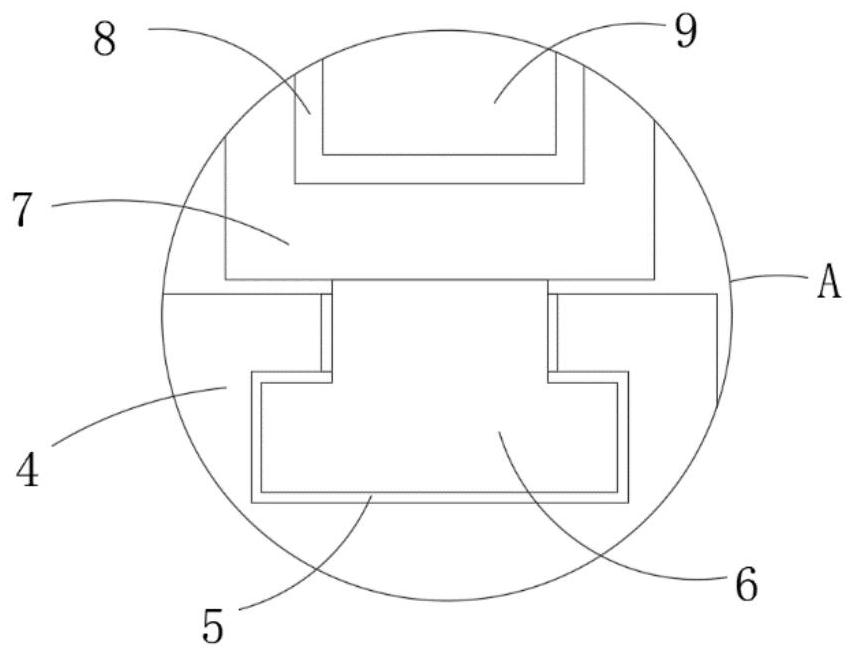

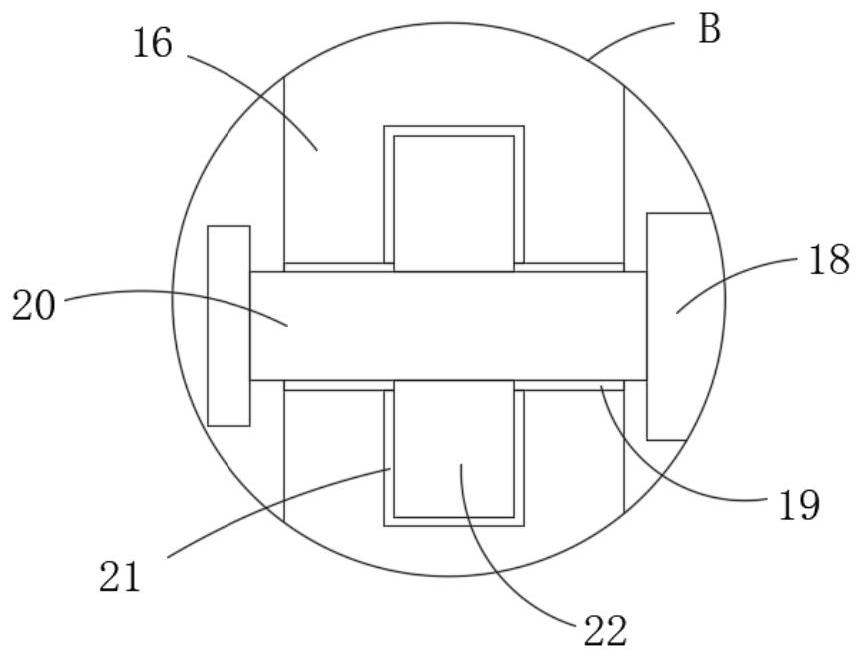

[0019] refer to Figure 1-4 , a wind tunnel test device for wind load of arc-shaped conductors, comprising a base 1 fixedly connected to the ground 38, a rotating port 2 is provided on the upper end surface of the base 1, and a rotating disk 3 is rotatably connected in the rotating port 2. 2 is set in a T shape, the shape of the rotating disk 3 is set to match the rotating port 2, and the T-shaped setting enables the rotating disk 3 to rotate stably in the rotating port 2 without detachment, which can make the subsequent wind tunnel test. More stable, the inner wall of the rotating port 2 is provided with a plurality of threaded holes 31 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com