Transducer array element forming device for controlling pre-tightening force and operation method

A molding device and transducer technology, applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of fixed frequency of array elements that cannot be modified, long time required for glue curing, and decreased preload consistency. Achieve the effect of improving product consistency and qualification rate, convenient arrangement, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

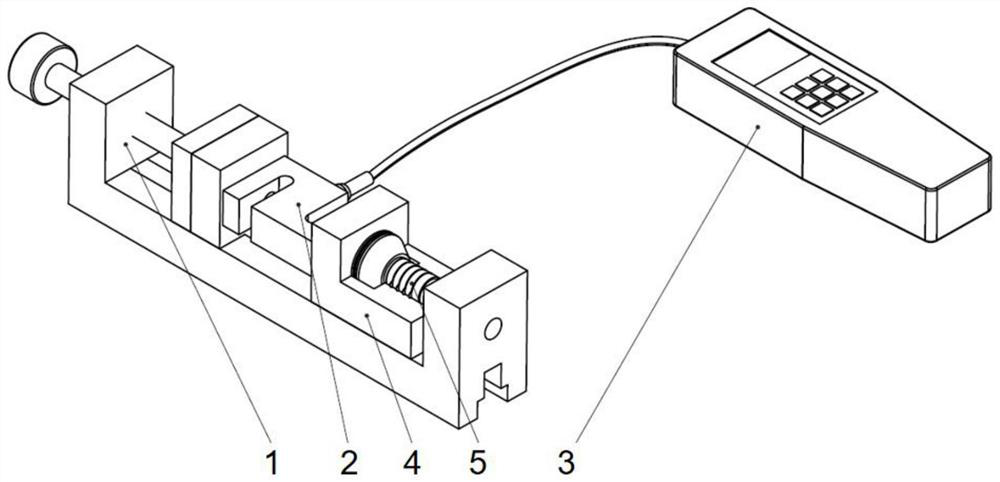

[0053] like figure 1 As shown, this embodiment includes: a main body support 1, a thrust gauge sensor 2, a thrust gauge controller 3, an array element mounting base 4, and a transducer longitudinal array element 5; the main body support 1 is installed with a thrust gauge sensor 2 and an array element Mounting base 4, thrust gauge sensor 2 is connected to thrust gauge controller 3, one end of thrust gauge sensor 2 is connected to array element mounting base 4, the other end is pushed along the axial direction by thrust rod 7, and the longitudinal array element 5 of the transducer is installed on the array element. On the installation base 4, the transducer longitudinal array element 5 is installed between the array element installation base 4 and the main body bracket 1. When the thrust rod 7 exerts a thrust on the thrust gauge sensor 2 and the array element installation base 4, the transducer is longitudinally driven. The array element 5 applies a pre-tightening force, and the...

Embodiment 2

[0058] Example 2 is a preferred example of Example 1.

[0059] like figure 1 As shown, this embodiment mainly includes three parts: a main body bracket 1 , a thrust gauge controller 3 , and an array element installation base 4 . When in use, a pre-tightening force is applied to the longitudinal array element 5 of the transducer through the thrust rod 7, and the frequency of the array element is controlled by monitoring the thrust displayed by the thrust gauge controller 3.

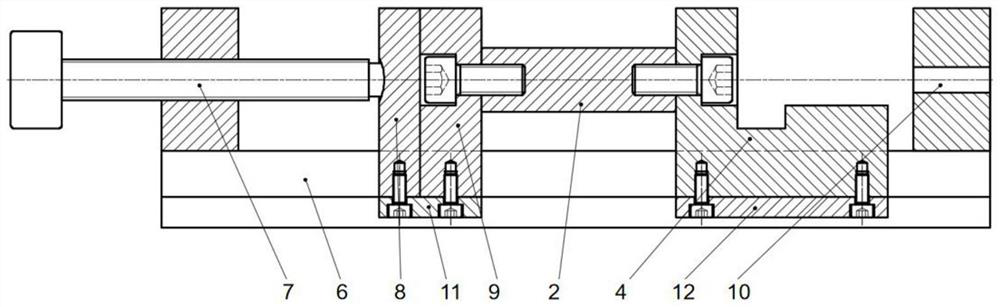

[0060] like figure 2 As shown, in this embodiment, the main body bracket 1 is about 350mm x 56mm x 90mm in length, width and height, and the material is stainless steel. The main body bracket 1 mainly includes: a guide base 6, a thrust rod 7, a thrust baffle 8, a sensor fixing plate 9, The first limiting plate 11 and the second limiting plate 12 . The thrust baffle 8 and the sensor fixing plate 9 are fixed by four M4 screws, and the thrust rod 7 has a thickness of M16×4, which passes through the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com