Fan impeller dismounting device

A fan impeller and impeller technology, applied in the field of fan impeller removal device, can solve the problems of affecting work efficiency, long heating time of the hub, cumbersome operation of grasping the horse and fixing the impeller, etc., so as to improve work efficiency and facilitate the installation and disassembly of tools Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

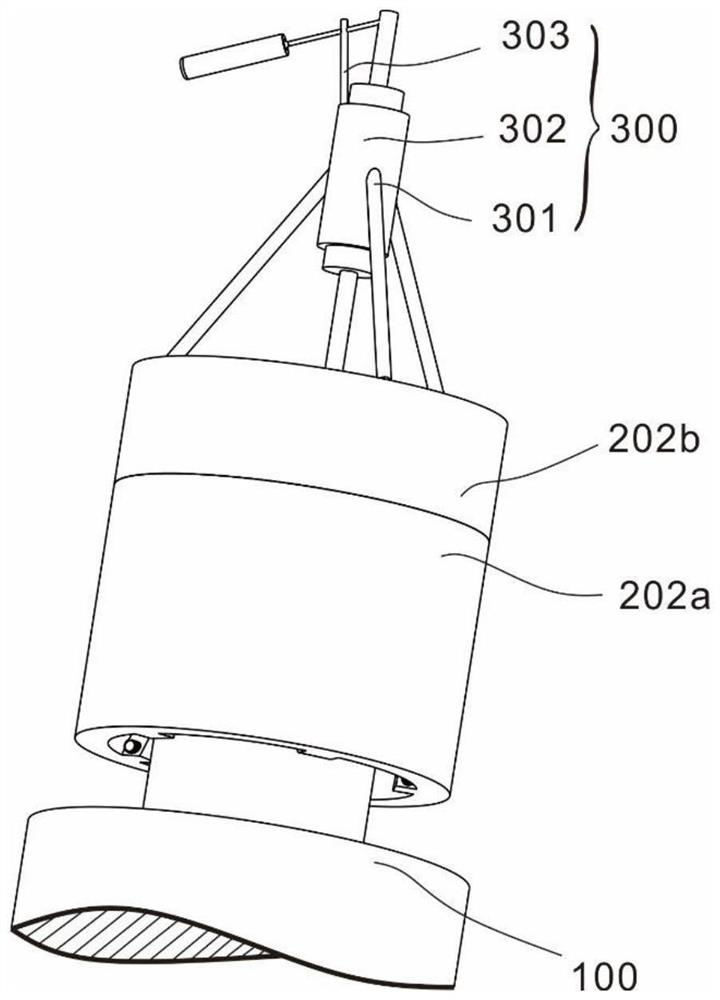

[0027] This embodiment provides a connecting tool for removing the impeller of a shaft-mounted fan, such as Figure 1 to Figure 3 ,

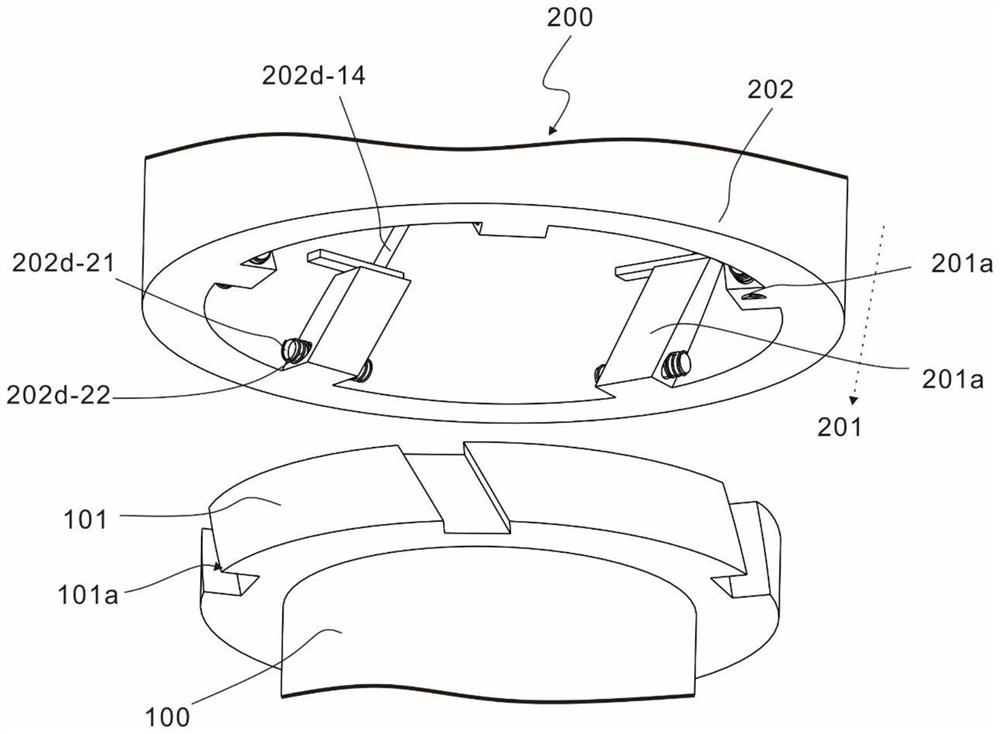

[0028] The device includes an impeller 100, the impeller 100 includes a first connecting piece 101, the first connecting piece 101 is annular, and the first connecting piece 101 is fixed on the upper end of the impeller 100; the connecting piece 200, the connecting piece 200 includes a second connecting member 201 and a rotating assembly 202, the second connecting member 201 is disposed at the lower end of the rotating assembly 202, and the second connecting member 201 is connected with the first connecting member 101; and, the push rod assembly 300, so The push rod assembly 300 is fixed on the rotating assembly 202 .

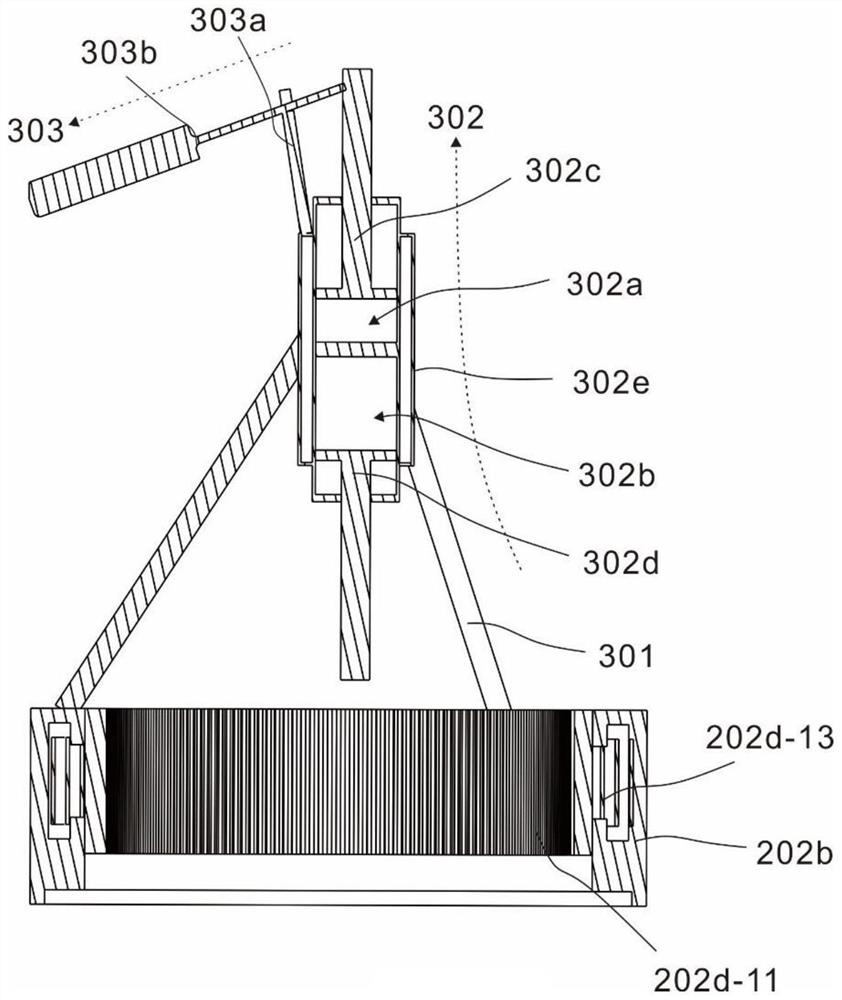

[0029] The push rod assembly 300 includes a fixed bracket 301 and a pressing mechanism 302 , one side of the fixed bracket 301 is fixedly connected to the side wall of the pressing mechanism 302 , and the other end of the fixed ...

Embodiment 2

[0042] This embodiment provides a connecting tool for removing the impeller of a shaft-mounted fan, such as Figure 1 to Figure 6 On the basis of Embodiment 1, this embodiment is different from Embodiment 1 in that:

[0043] The rotating assembly 202 includes a first drum 202a, a second drum 202b, a one-way mechanism 202c and a locking mechanism 202d. The first drum 202a and the second drum 202b are placed coaxially, and the second drum 202b is located in the first drum. The upper end of the drum 202a is rotatably connected to the first drum 202a, the second connecting piece 201 is arranged on the inner wall of the first drum 202a, the one-way mechanism 202c and the locking mechanism 202d are provided at the connection between the second drum 202b and the first drum 202a. Inside the second drum 202b and the first drum 202a.

[0044] A one-way mechanism 202c is provided at the connection between the second drum 202b and the first drum 202a, so that the relative movement betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com