Gas leakage prevention device for gas cylinder carrying

An anti-leakage and gas cylinder technology, applied in the field of handling, can solve problems such as hidden safety hazards and cannot be detected in real time, and achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

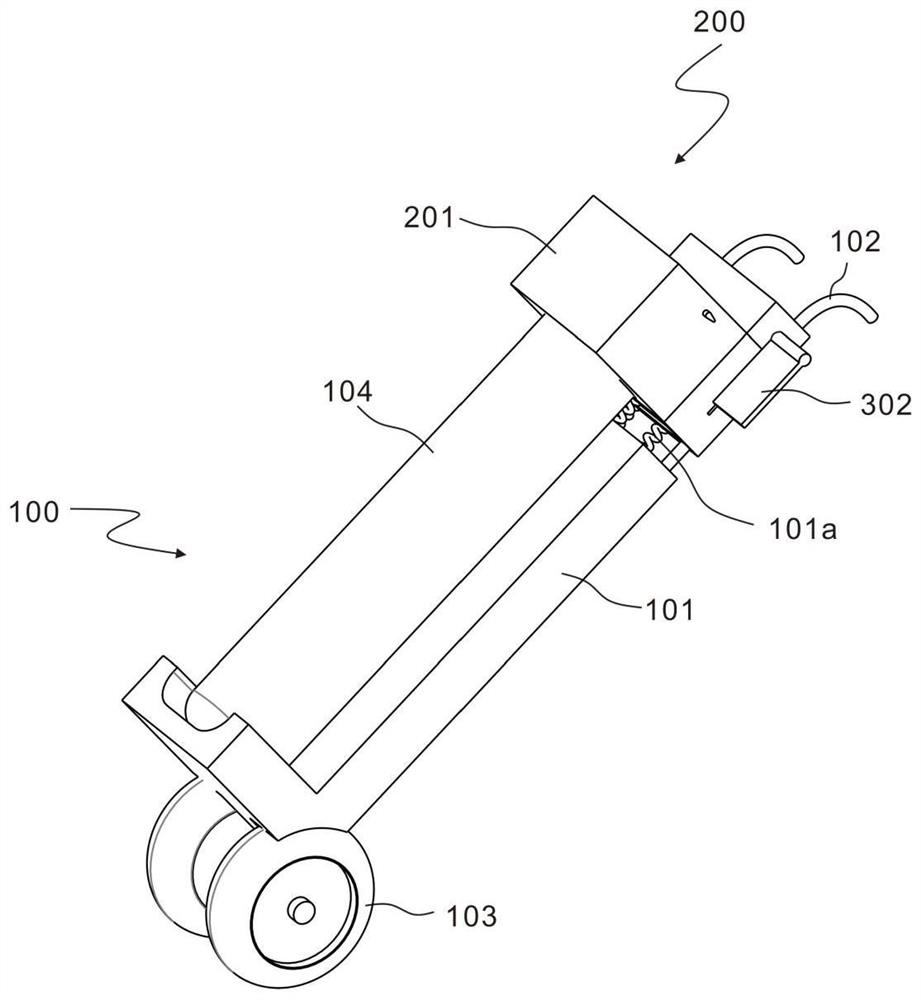

[0032] refer to Figure 1 to Figure 6 , which is the first embodiment of the present invention. This embodiment provides a leak-proof device for handling gas cylinders, including a transport unit 100, and the transport unit 100 includes a transport frame 101, a handle bar 102, a universal wheel 103 and a gas cylinder 104, The gas cylinder 104 is placed on the transport rack 101, one end of the grip rod 102 is embedded in the transport rack 101, the universal wheel 103 is arranged at the bottom of the transport rack 101, the gas cylinder 104 is placed on the transport rack 101, hold the grip rod 102, The bottle 104 is transported to the designated location, and;

[0033] Sealing unit 200, the sealing unit 200 includes a fixing block 201, a sealing cavity A disposed inside the fixing block 201, a card and assembly 202 and a driving assembly 203, the top of the gas cylinder 104 is embedded in the sealing cavity A, and the card and assembly 202 are arranged in the sealing cavity ...

Embodiment 2

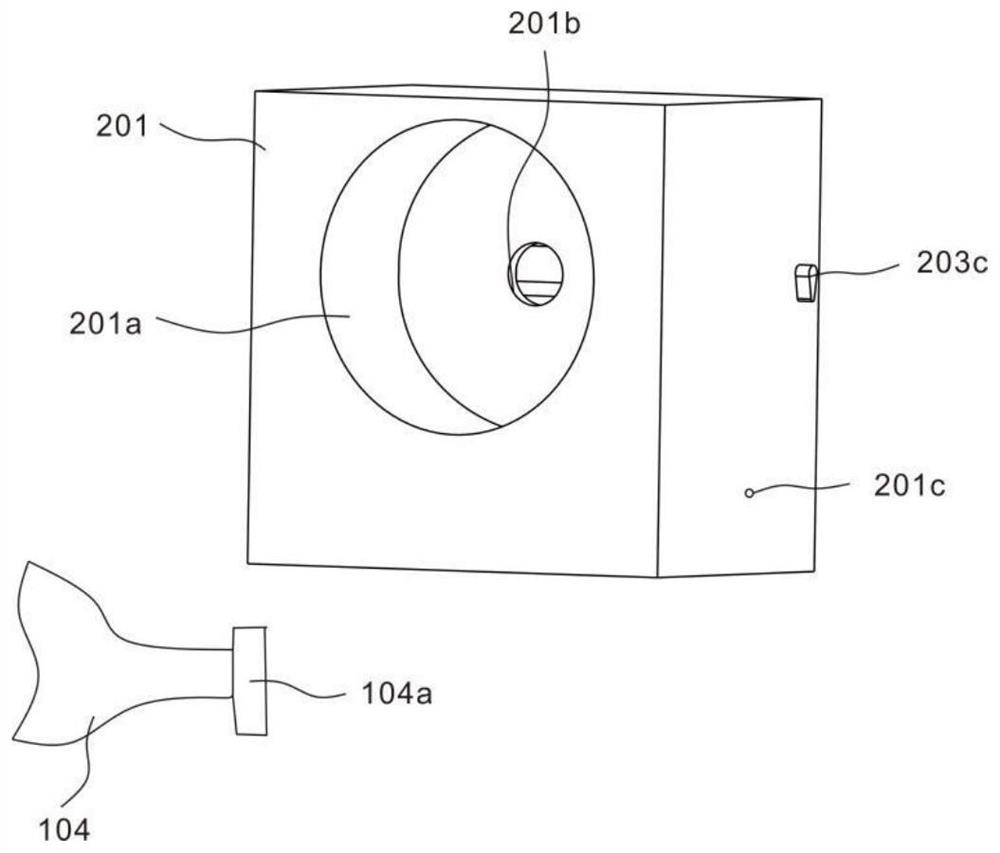

[0036] refer to Figure 2 to Figure 4 and Figure 8 , is the second embodiment of the present invention. This embodiment is based on the previous embodiment. The fixing block 201 is provided with a groove 201a and an air hole 201b. In the groove 201a and communicate with the sealing cavity A, the gas cylinder 104 is provided with a valve port 104a, the gas cylinder 104 is embedded in the groove 201a, the valve port 104a is embedded in the air hole 201b, and the groove 201a is set to fit the shape of the air hole 201b, so that the gas cylinder 104 and the fixing block 201 can be tightly combined to prevent the gas in the gas cylinder 104 from leaking into the air to cause pollution and harm. The valve port 104a is the most likely location for gas leakage, and is arranged in the air hole 201b. On the one hand, the valve port 104a can be For protection, to prevent the valve port 104a from being collided during transportation to cause gas leakage, on the one hand, the gas leaked ...

Embodiment 3

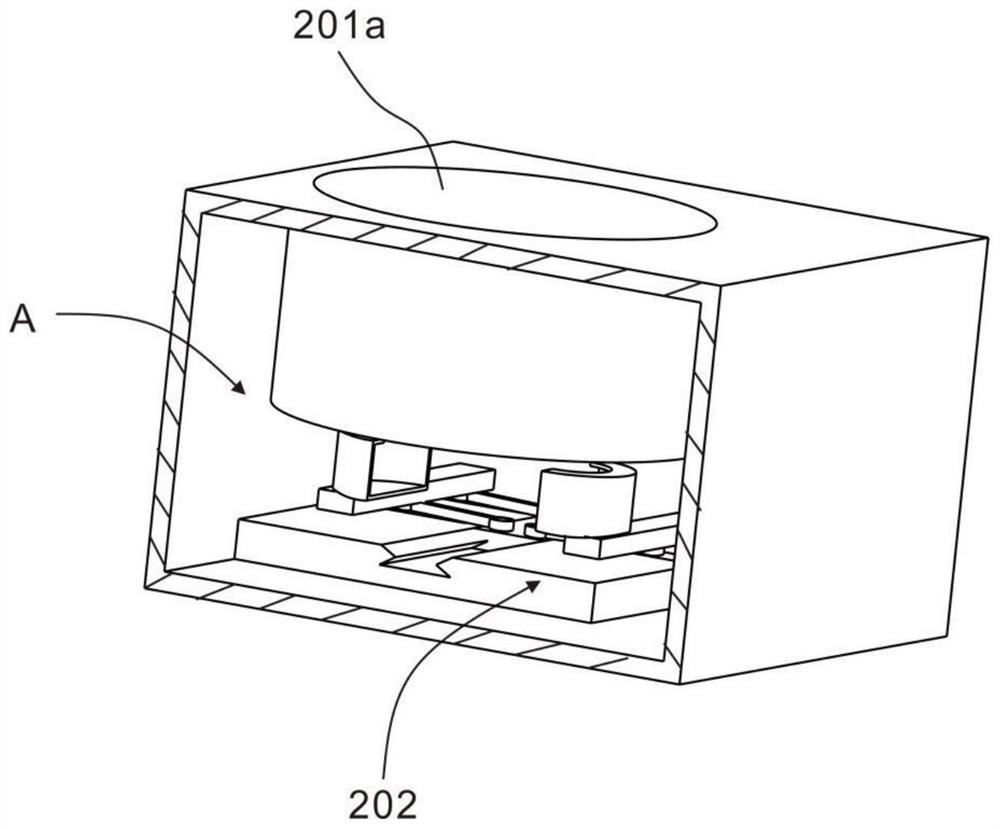

[0041] refer to Figure 5 to Figure 8 , which is the third embodiment of the present invention. This embodiment is based on the previous embodiment. The track tube 203a is provided with a track 203a-1, the rotation column 203b is provided with a track column 203b-1, and the track column 203b-1 is embedded in the track 203a. In -1, when the rotating column 203b rotates, the orbital column 203b-1 will move in the direction of the rotating column 203b, and the orbital column 203b-1 is limited to move within the orbit 203a-1, so the orbital tube 203a will be moved. Move forward.

[0042] The air pressure push plate 301 is provided with a push column 301a and a first spring 301b. The first spring 301b is sleeved on the push column 301a. The increase of the air pressure in the air pressure chamber B will cause the air pressure push plate 301 to be squeezed, and the first spring 301b will be compressed. When compressed, the pushing column 301a will pass through the air pressure cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com