Novel waste catalyst cleaning and ball-milling process

A technology of waste catalysts and cleaning balls, applied in inorganic chemistry, tungsten compounds, cleaning methods and appliances, etc., can solve the problems of waste of resources, pollution of the environment, etc., and achieve the effect of reducing waste, reducing pollution, and avoiding direct burying of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0068] Example 1:

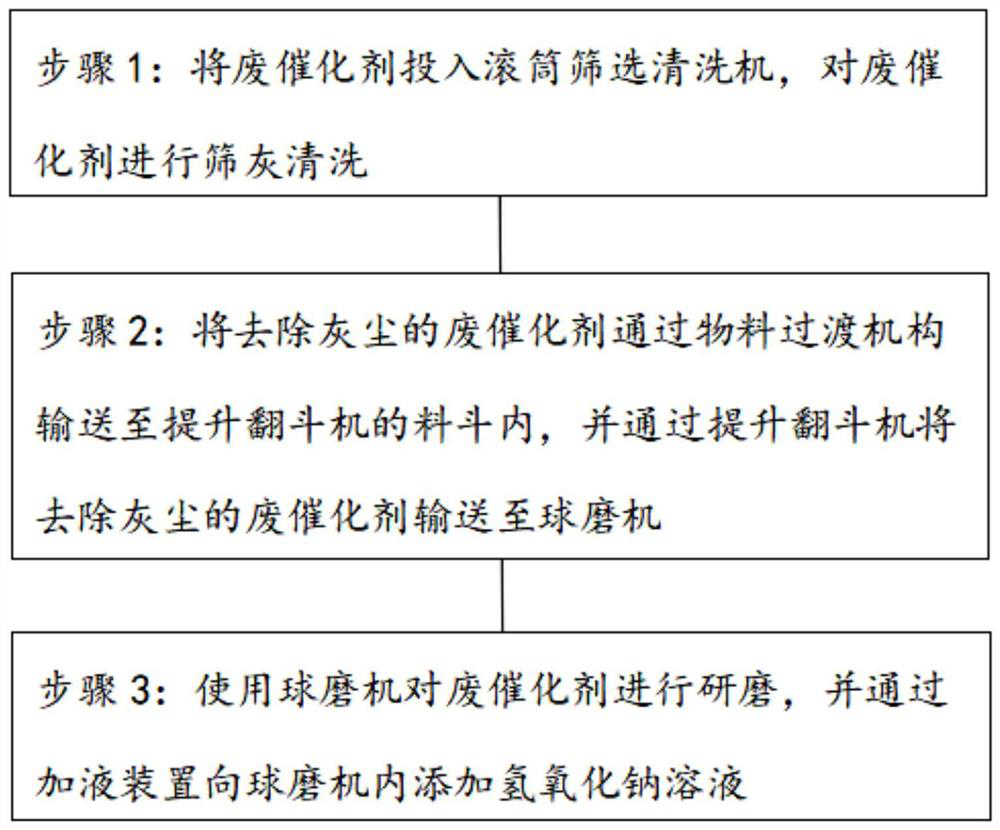

[0069] The embodiment of the present invention provides a novel waste catalyst cleaning ball milling process, such as Figure 1-Figure 9 shown, including the following steps:

[0070] Step 1: put the waste catalyst into the drum screening and cleaning machine 1, and screen the waste catalyst for ash cleaning;

[0071] Step 2: The waste catalyst for removing dust is transported to the bucket 4 of the lifting tipper 3 through the material transition mechanism 2, and the waste catalyst for removing dust is transported to the ball mill 5 through the lifting tipper 3;

[0072] Step 3: Use the ball mill 5 to grind the spent catalyst, and add sodium hydroxide solution to the ball mill 5 through the liquid addition device 6 .

[0073] The working principle and beneficial effects of the above technical solutions are as follows: first, the waste catalyst is put into the drum screening and cleaning machine 1, and the waste catalyst is screened and cleaned, and then ...

Example Embodiment

[0074] Example 2

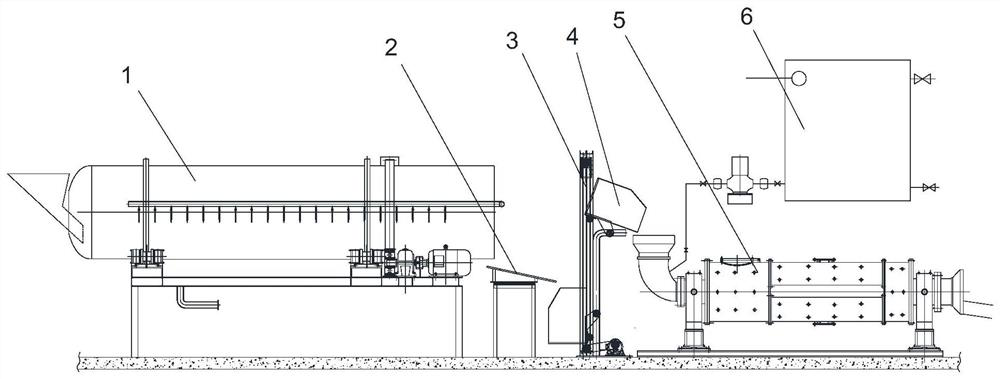

[0075] On the basis of the above Example 1, as Figure 2-Figure 7 As shown, in the step 1, the drum screening and cleaning machine 1 includes:

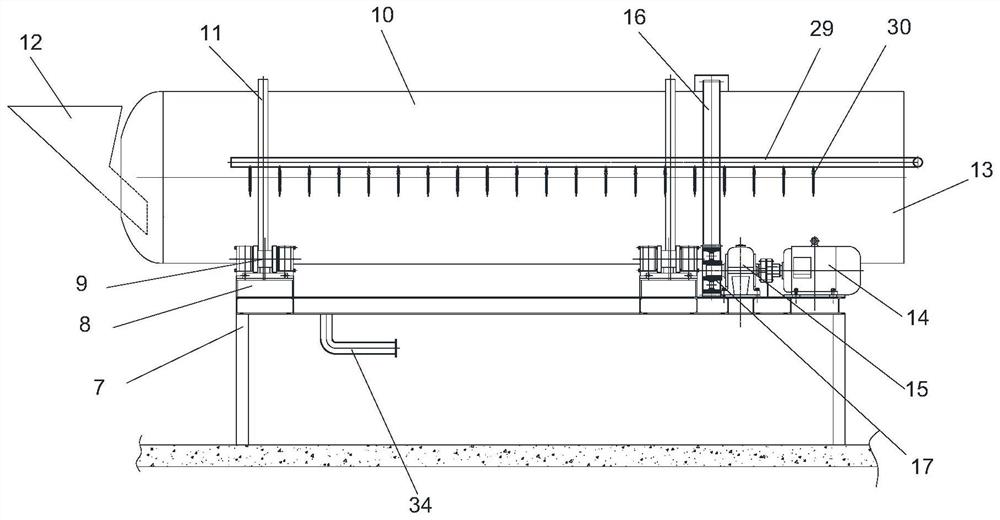

[0076] The first base 7, the upper surface of the first base 7 is fixedly provided with two sets of support mechanisms, the support mechanism includes a support seat 8 and a supporting wheel 9 that are symmetrically arranged in the front and rear, the bottom surface of the support seat 8 and the first base 7 The upper surface is fixedly connected, the supporting wheel 9 is rotatably arranged in the support base 8, and the left and right sides of the supporting wheel 9 are provided with limit plates;

[0077] The trommel screen body 10, the trommel screen body 10 is arranged above the support base 8, the outer circumference of the trommel screen body 10 is provided with a fixing ring 11, and the inner ring of the fixing ring 11 is fixedly connected with the outer wall of the trommel screen body 10, The outer circum...

Example Embodiment

[0100] Example 3

[0101] On the basis of Example 2, as Figure 8 As shown, a guiding device is also arranged in the lifting dumper 3, and the guiding device includes:

[0102] a first sliding rod 74, the first sliding rod 74 is vertically arranged, and the upper end of the first sliding rod 74 penetrates the horizontal plate 44, extends above the horizontal plate 44, and is slidably connected with the horizontal plate 44;

[0103]a buffer block 75, the buffer block 75 is arranged on the lower end of the first sliding rod 74, and the upper end of the buffer block 75 is fixedly connected with the lower end of the first sliding rod 74;

[0104] Two swinging plates 76, the two swinging plates 76 are symmetrically arranged on the front and rear sides of the first sliding rod 74, and one end of the swinging plate 76 is hingedly connected to the lower surface of the transverse plate 44;

[0105] A connecting rod 77, the connecting rod 77 is arranged between the buffer block 75 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com