High-altitude support-free segmented butt joint installation method for section steel beams

A technology of butt joint installation without brackets, which is applied in the processing of building materials, construction, and building construction. It can solve the problems of time-consuming, uneconomical, and exceeding the capacity of lifting equipment when erecting brackets, so as to shorten the installation time and ensure safety. High reliability and reduced usage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] 1. Determine the segment size of the steel beam

[0046] The segment size of the steel beam is determined according to the actual situation on site, and priority is given to the bending resistance of the upper steel column (that is, the position close to the upper part when the steel column is placed vertically), the capacity of on-site lifting equipment, and site problems. Generally, it is divided into three sections, namely the cantilevered steel beam section on the left and right sides and the empty steel beam section in the middle. The section length of the steel beam follows the principle of indwelling construction joints, and the section position is set within 1 / 3 of the span on both sides of the steel beam.

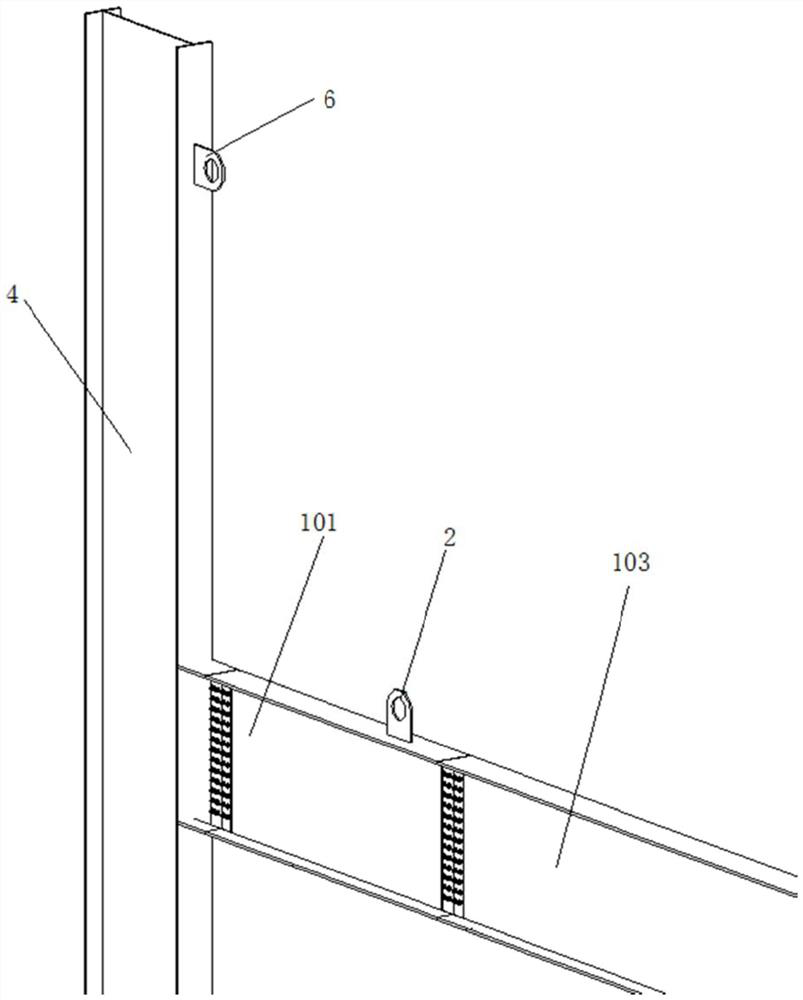

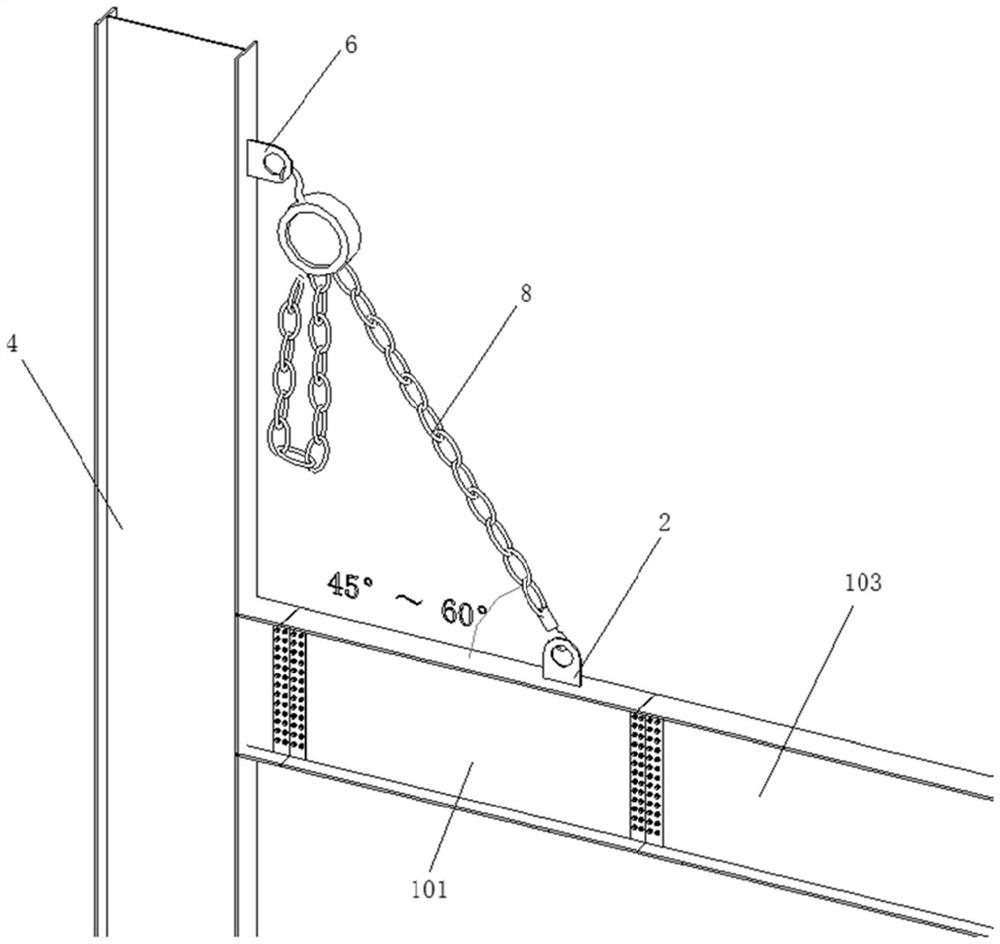

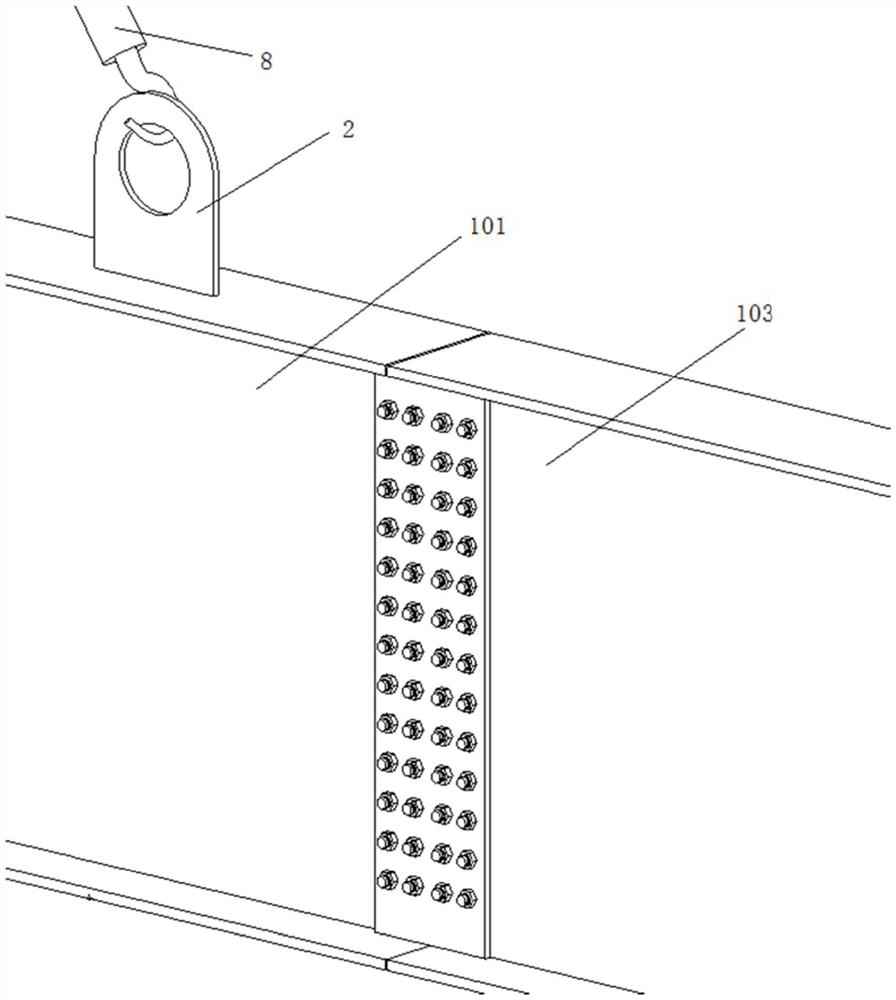

[0047] 2. Set the hanging point (that is, the position of the lifting ring)

[0048] The cable used in this embodiment is a chain hoist, and the hanging point of the chain hoist needs to be set on the upper steel column and the free end of the cantilevered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com