Method for determining bearing capacity of in-service offshore platform crane

A technology for offshore platforms and cranes, applied in instrumentation, geometric CAD, design optimization/simulation, etc., can solve problems such as rod corrosion, scrap, increase production costs, etc., and achieve the effect of eliminating modeling errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

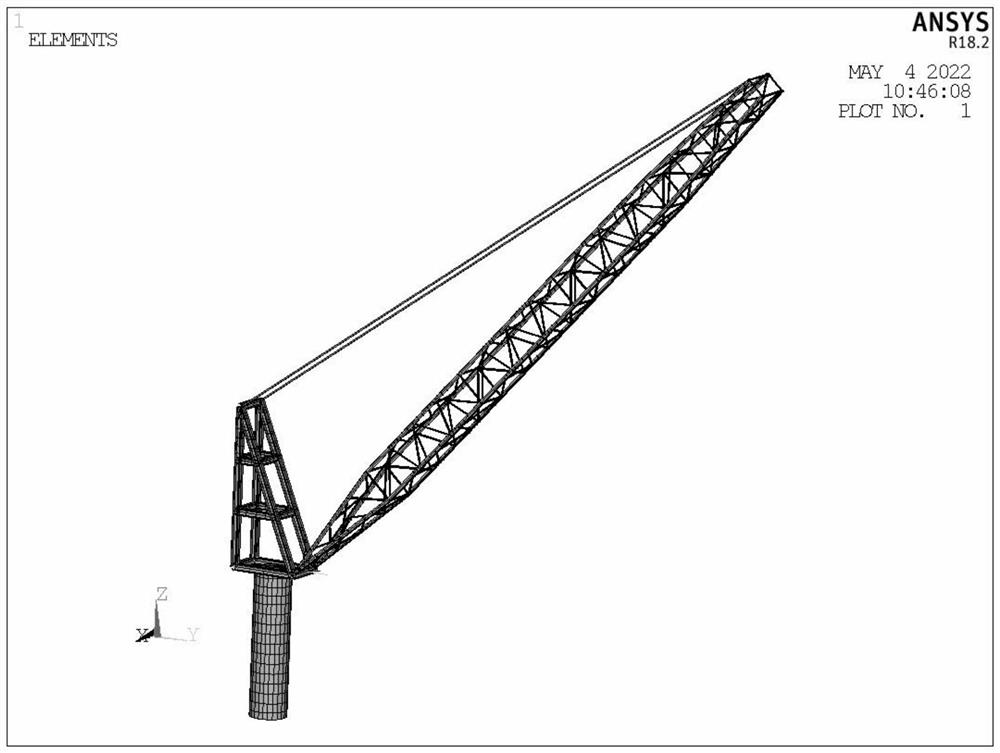

[0050] The present invention will be further described below in conjunction with the accompanying drawings:

[0051] First, the specific parameters of the crane in this embodiment are given, the maximum carrying capacity of the crane is 150kN, and the boom of the crane is divided into five sections.

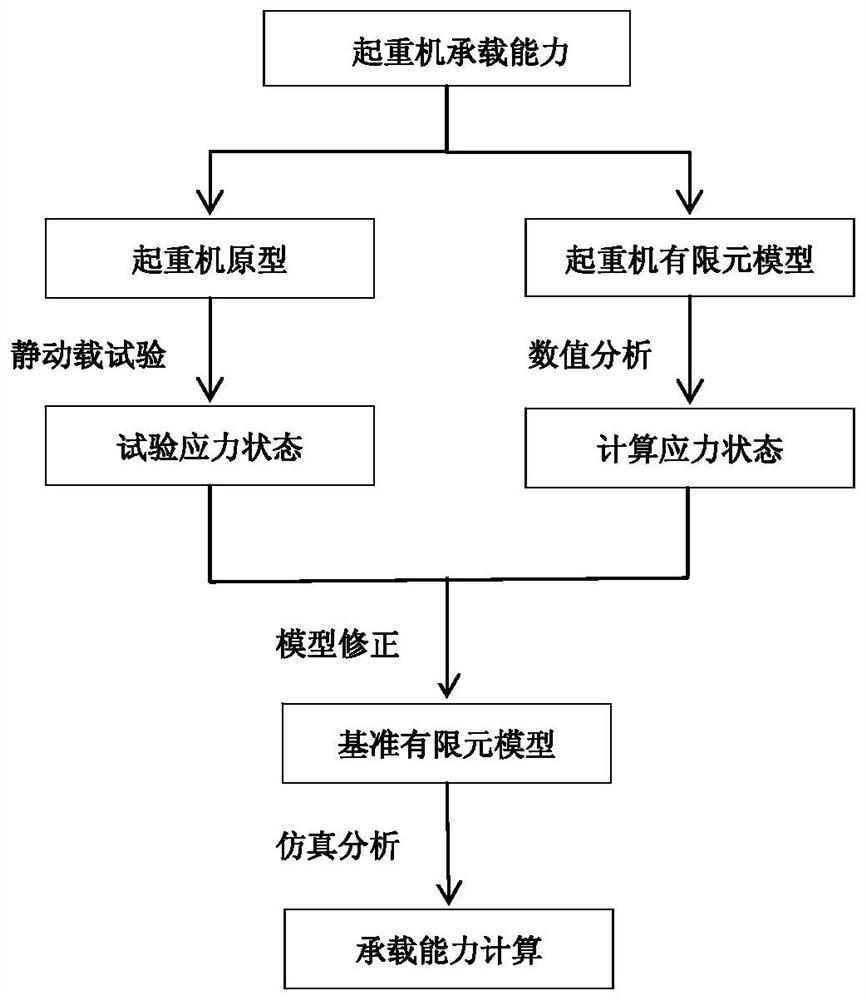

[0052] The described method for determining the bearing capacity of an in-service offshore platform crane includes the following steps:

[0053] The first step is to carry out the overall structure static and dynamic load strain test on the target offshore platform crane;

[0054] This step is carried out according to the following path:

[0055] Carry out local bearing capacity test of the offshore platform crane to be tested, and collect the stress data of the boom lifting from 50° to 60°, 70° and 80° when it is empty and from 50° to 60° and 70° when it is loaded. ° and 80° stress data, the load is realized by hanging the water bag on the main hook of the crane. After collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com