Redundant leftover material cutting-off equipment for folding machine and operation method of redundant leftover material cutting-off equipment

An operation method and technology of a folding machine, applied in metal processing and other directions, can solve the problems of paper collapse, affecting the integrity of paper, and inaccurate paper stacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

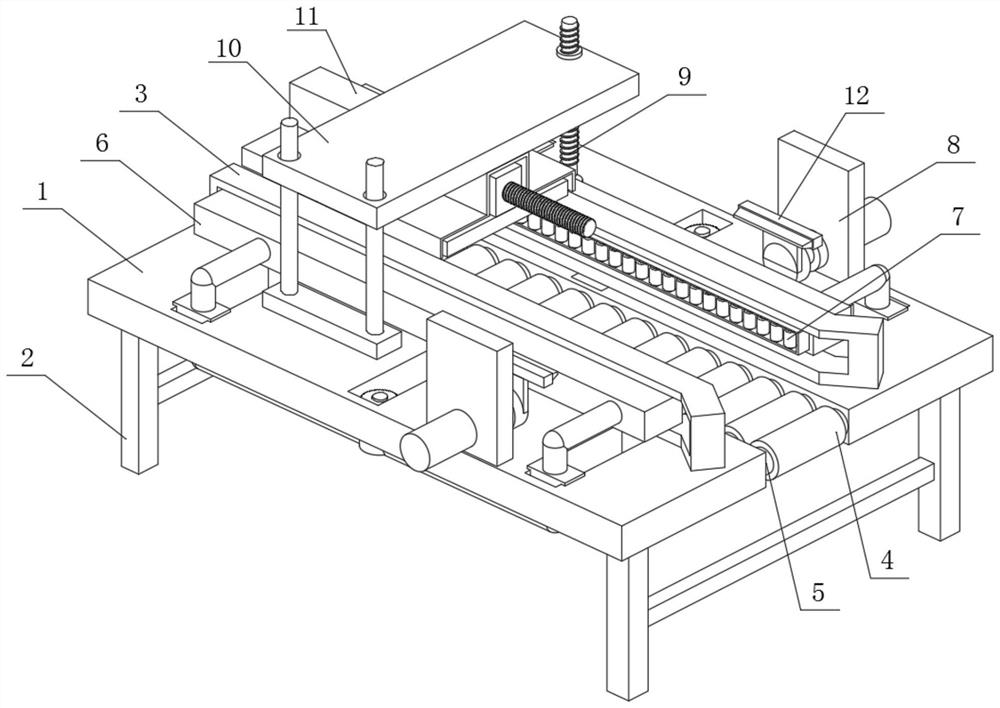

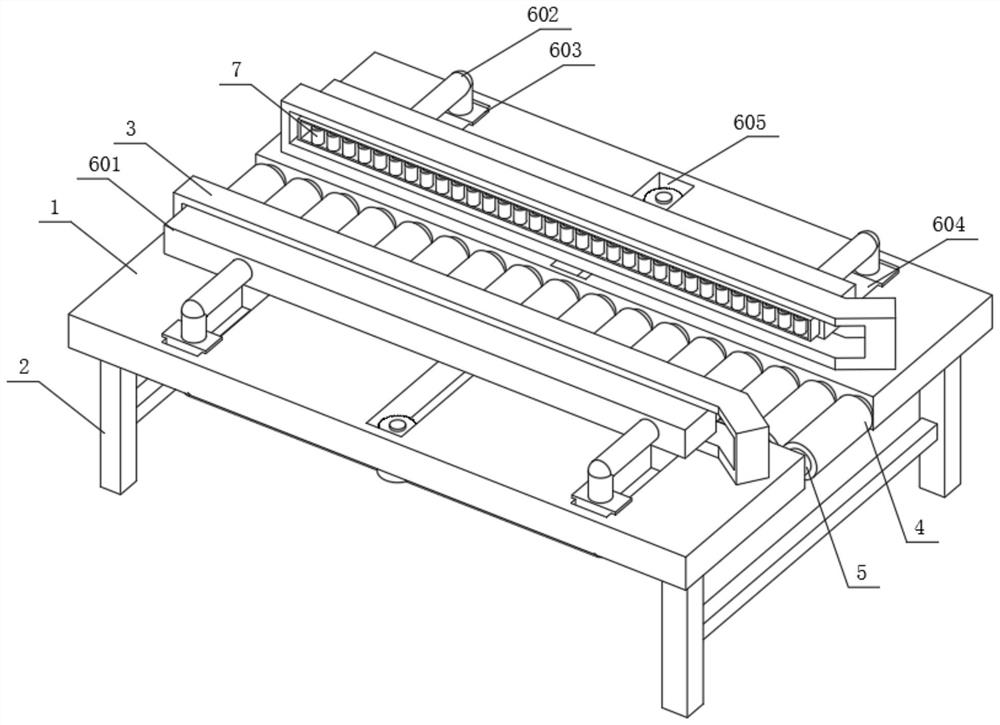

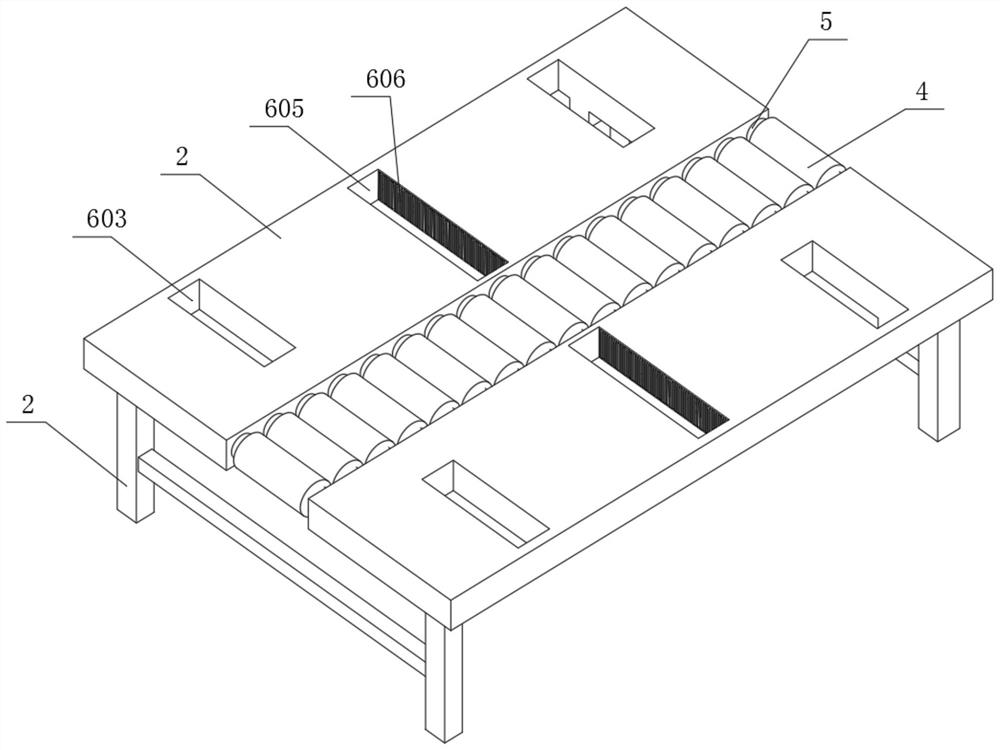

[0037] In order to further understand the content, features and effects of the present invention, the following embodiments are exemplified and described in detail below with the accompanying drawings.

[0038] The structure of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] like Figure 1 to Figure 8As shown in the figure, a redundant corner material cutting device for a folding machine and an operation method thereof include a work board 1, a support leg 2 is fixedly connected to the lower surface of the work board 1, an opening is arranged in the middle of the work board 1, and a fixed connection between the openings is provided. A number of evenly distributed rotating shafts 5, each rotating shaft 5 is rotatably installed with a drum 4, the upper surface of the work plate 1 is fixedly connected with limit plates 3 located on both sides of the drum 4, and clamping assemblies 6 are installed in the limit plates 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com