Method for improving microbial conversion concentration of 5-hydroxytryptophan

A technology for microbial transformation and hydroxytryptophan, which is applied in the fields of genetic engineering and biocatalysis, and can solve problems such as increasing costs and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Molecular Cloning

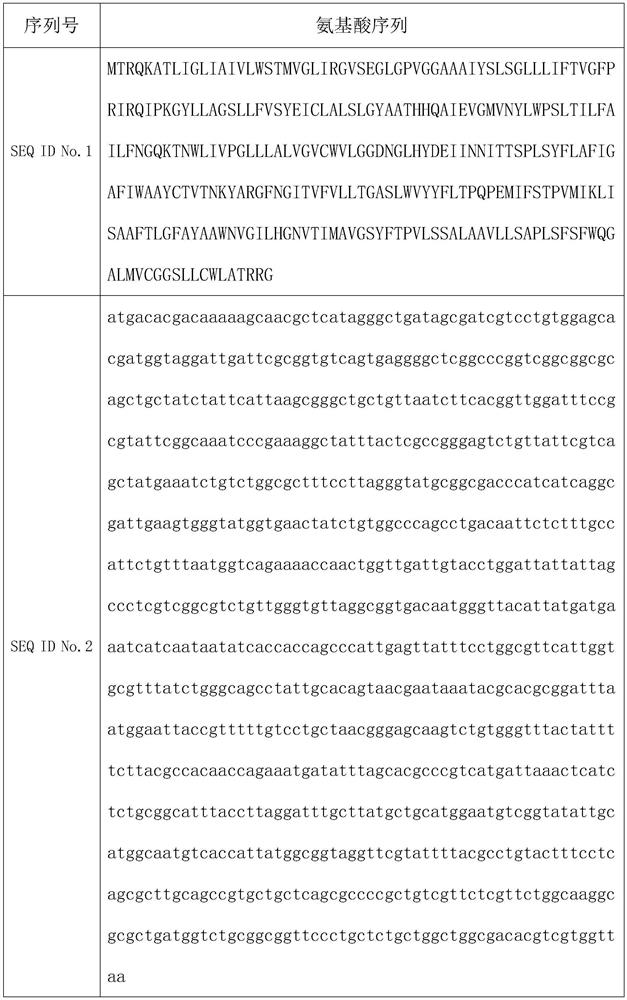

[0029] Design specific primer pairs to introduce the desired substitution at the corresponding base at the desired mutated amino acid position. Using the extracted Escherichia coli K12 wild-type MG1655 genomic DNA as a template, the coding SEQ ID No. 1 was amplified by PCR. The nucleic acid sequence of its coding region is shown in SEQ ID No.2.

[0030] The purified PCR product was digested with NdeI-KpnI, and then ligated with the pACYCDuet-1 vector digested at the same site using T4 ligase. The ligation product was transformed into E. coli BL21 (DE3) competent cells, spread on LB agar medium (containing 35 mg / L chloramphenicol), and single colonies were picked to LB liquid medium (containing 35 mg / L chloramphenicol) ), and the plasmid was extracted and sequenced to verify the correctness of the mutation. The extracted plasmids were stored at -80°C for later use.

Embodiment 2

[0031] Example 2: Experiment of promoting the production of 5-hydroxytryptophan in Escherichia coli by overexpressing the transporter encoded by SEQ ID No. 1

[0032] 5-Hydroxytryptophan encoding engineered bacterial tryptophan-5-hydroxylase (T5H), pterin-4α-methanolamine dehydratase (PCD) and dihydromonopterin reductase (DHMR) Production bacterial strain was prepared into chemically competent, then transformed into the plasmid constructed in Example 1, cultivated in the LB agar medium containing the chloramphenicol of 35mg / L, and selected single clone to LB liquid medium (containing 35mg / L). chloramphenicol), incubated at 37°C with shaking for 8h. Transfer 1 mL of culture to 250 mL of fresh TB liquid medium (containing 35 mg / L of chloramphenicol), incubate with shaking at 37°C until OD600 reaches about 5, and insert all the fermentation broth with 2.5 L of fermentation medium. 5L fermenter.

[0033] The fermenter medium formula is (ammonium sulfate 1g / L, dipotassium hydroge...

Embodiment 3

[0037] Example 3: Blank comparison experiment

[0038] The specific experimental procedure is the same as that in Example 2, the only difference is that the transferred plasmid is the pACYCDuet-1 empty plasmid.

[0039] The substrate conversion situation of Example 3 is shown in Table 2:

[0040] time / h Tryptophan g / L 5-Hydroxytryptophan g / L 24 0.96 3.99 27.5 1.57 5.22 31.2 1.13 6.56 35.3 1.25 7.9 37.3 1.28 8.01 40.8 1.68 8.16 43.5 2.07 8.19 48.7 3.01 8.41

[0041] Table 2

[0042]Combining the results of Examples 2 and 3, it can be clearly observed that after overexpressing the transporter, the production rate of 5-hydroxytryptophan can be maintained at a high level, while in the control experiment without overexpressing the transporter, The conversion of 5-hydroxytryptophan became slower and slower, and it stopped accumulating at about 8g / L. It can be seen that the transporter encoded by SEQ ID No. 1 can pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap