Spot welding nugget quality prediction method and equipment based on multi-factor mapping model

A quality prediction and mapping model technology, applied in character and pattern recognition, data processing applications, instruments, etc., can solve problems such as difficulty in finding information, lack of data processing and analysis capabilities, and difficulty in effectively utilizing information, and achieves high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

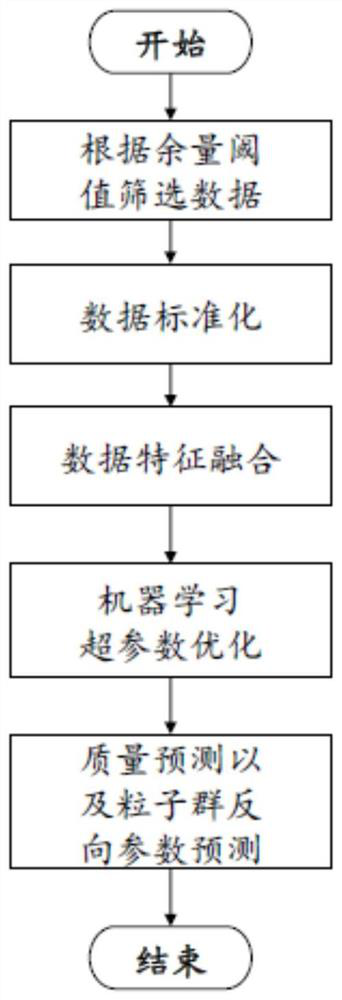

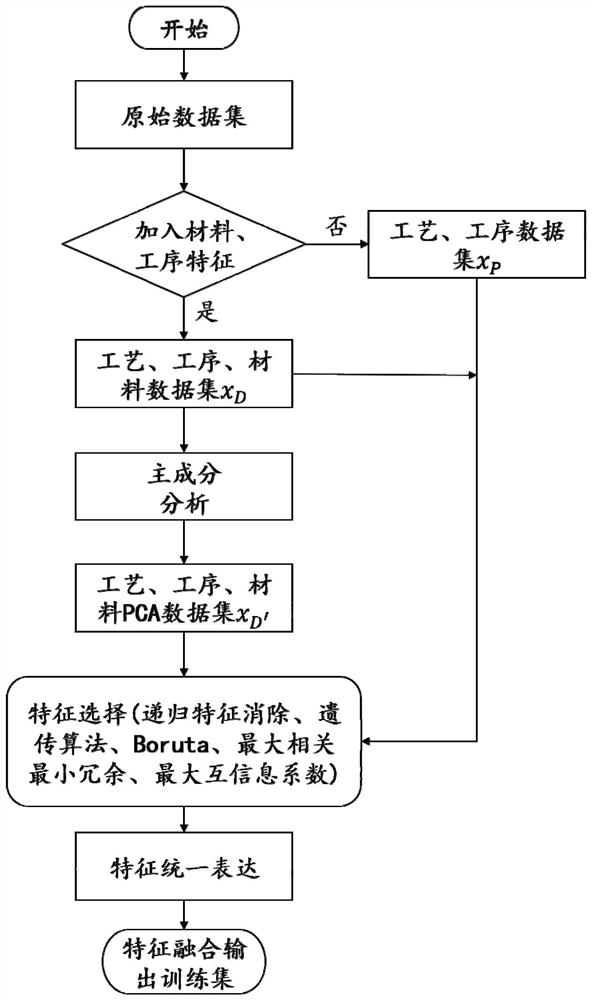

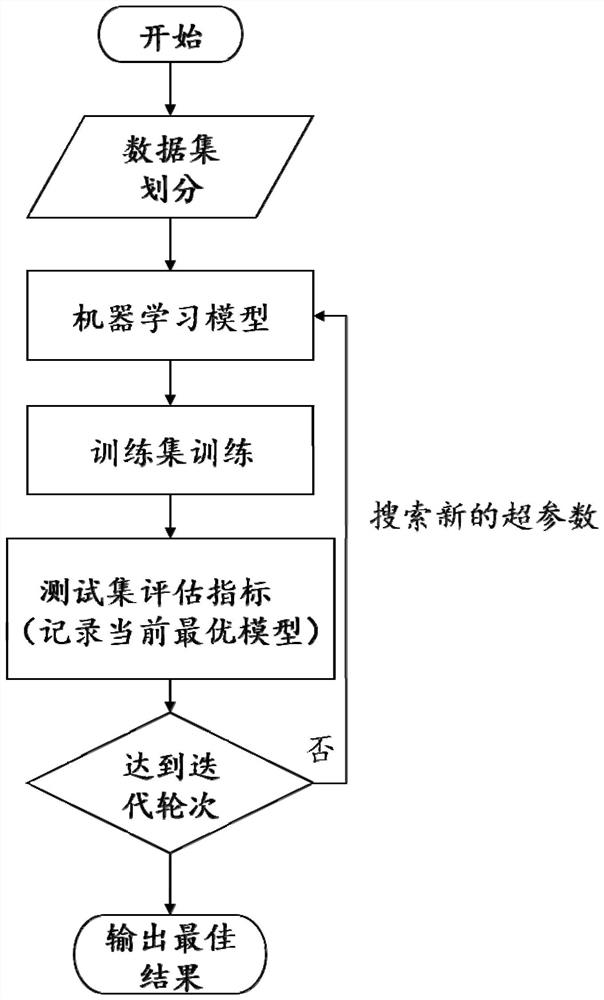

[0039] Example one, as figure 1 As shown, the present embodiment discloses a method for predicting the quality of spot welding nuggets based on a multi-factor mapping model. The main steps include:

[0040] Step 1: Raw data screening.

[0041] According to the design requirements of different parts, the margin threshold T of different combinations of welding materials is determined, and the values that do not meet the margin threshold T in the original data of body-in-white welding are filtered to obtain the original data set.

[0042] At present, in actual production, it is determined that the nugget larger than the designed nugget diameter is the result of meeting the performance requirements of all aspects of the body-in-white. Because the pass rate of the spot welding nugget is guaranteed, the production margin is usually increased, such as increasing the welding current. , prolong the welding time, etc.

[0043] Although an excessively large margin nugget can meet the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap