Feeding mechanism for machined teeth

A technology of tooth processing and feeding, applied in the field of feeding mechanism to be processed by teeth, can solve the problems of high labor intensity, heavy weight, low processing efficiency of passive bevel gears, etc., and achieve the effect of reducing energy, stable transportation, and ensuring follow-up. normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

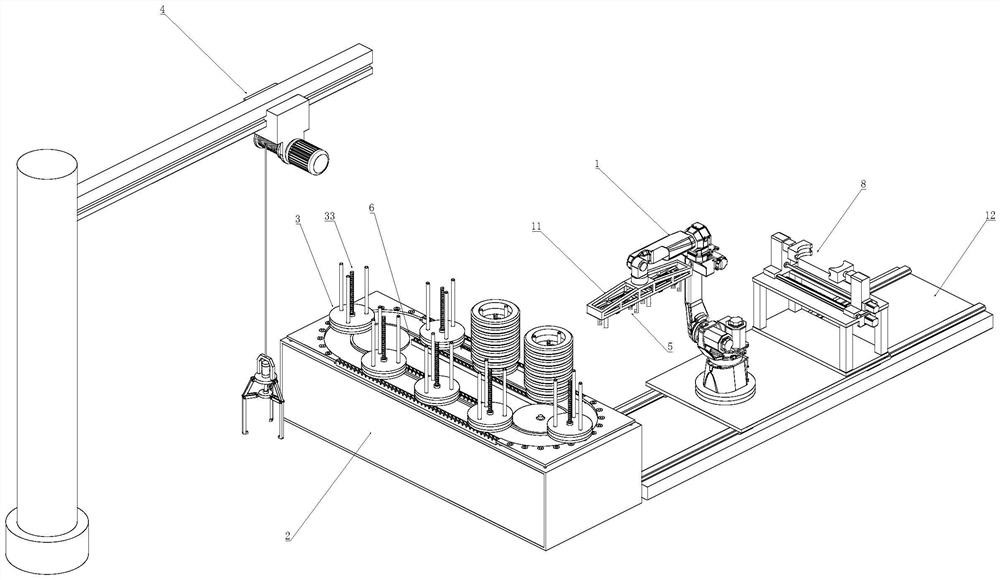

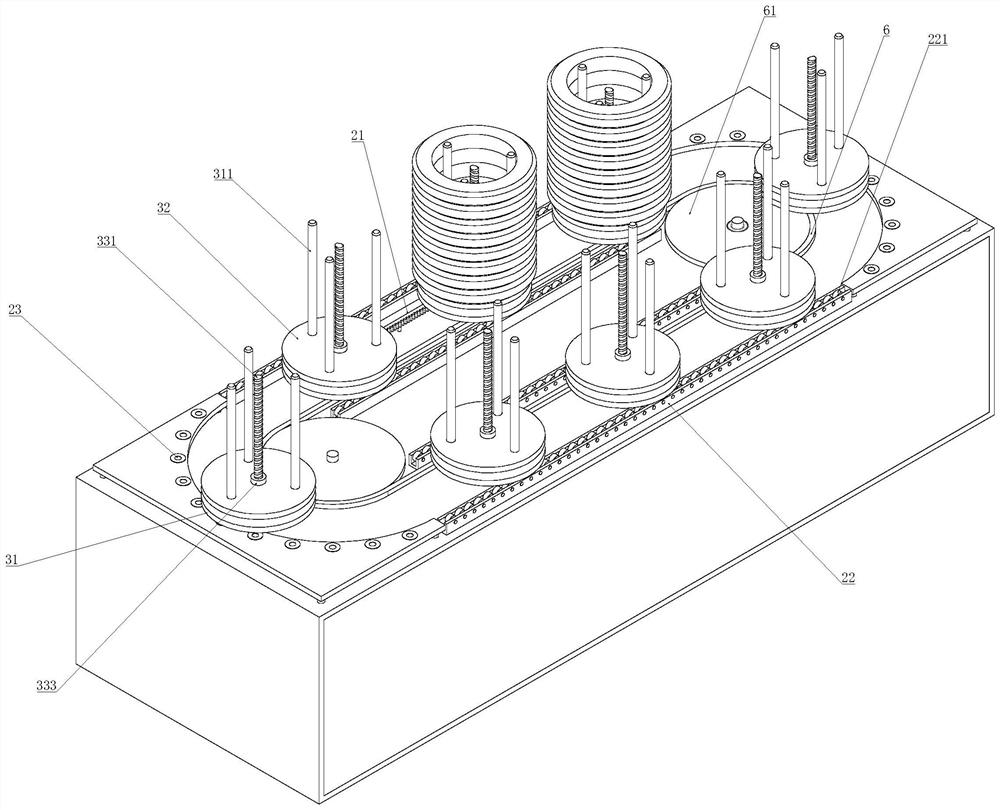

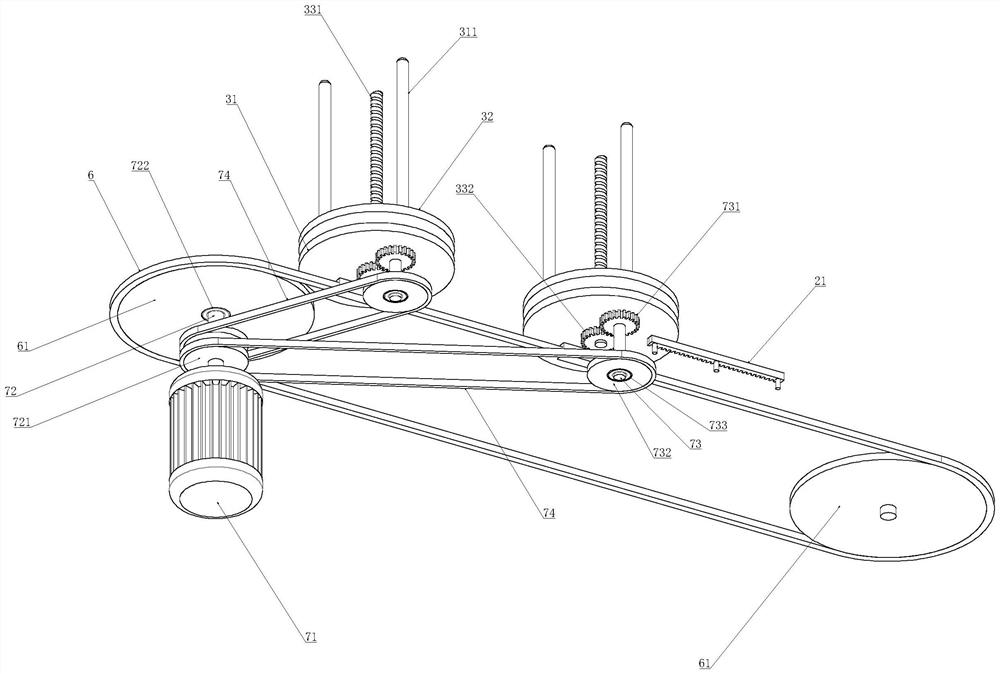

[0034] Example: a feeding mechanism for tooth processing, such as figure 1 , figure 2 As shown, it includes a manipulator 1, a conveying table 2, and a plurality of toothed fixing components 3 movably arranged on the conveying table 2. The output end of the manipulator 1 is connected with a turret 11, and the turret 11 is provided with a toothed clamping component 5 ; A conveyor chain is installed on the conveyor table 2, and a drive device 7 for driving the conveyor chain to move is provided on the conveyor table 2; The fixed rod 311 is located above the moving plate 31 through the fixed rod 311 to lift the plate 32. When the teeth need to be processed, the teeth lifting device 4 is used to lift a plurality of stacked teeth, and thread the teeth into In the fixed rod 311 on the moving plate 31, until the teeth are completely stacked on the lifting plate 32, the driving device 7 drives the transmission chain to transmit the moving plate 31, so that the moving plate 31 filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com