Vertical gear shifting device suitable for heading machine, heading machine and vertical gear shifting method of heading machine

A gear shifting device and roadheader technology, which is applied in hoisting devices, hoisting equipment safety devices, earthwork drilling and mining, etc., can solve problems such as difficult construction, decreased excavation verticality accuracy, and relative position changes of support arms, and achieves improvement. The effect of excavation and expansion, the design is simple and reliable, and the effect of fastening and matching is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

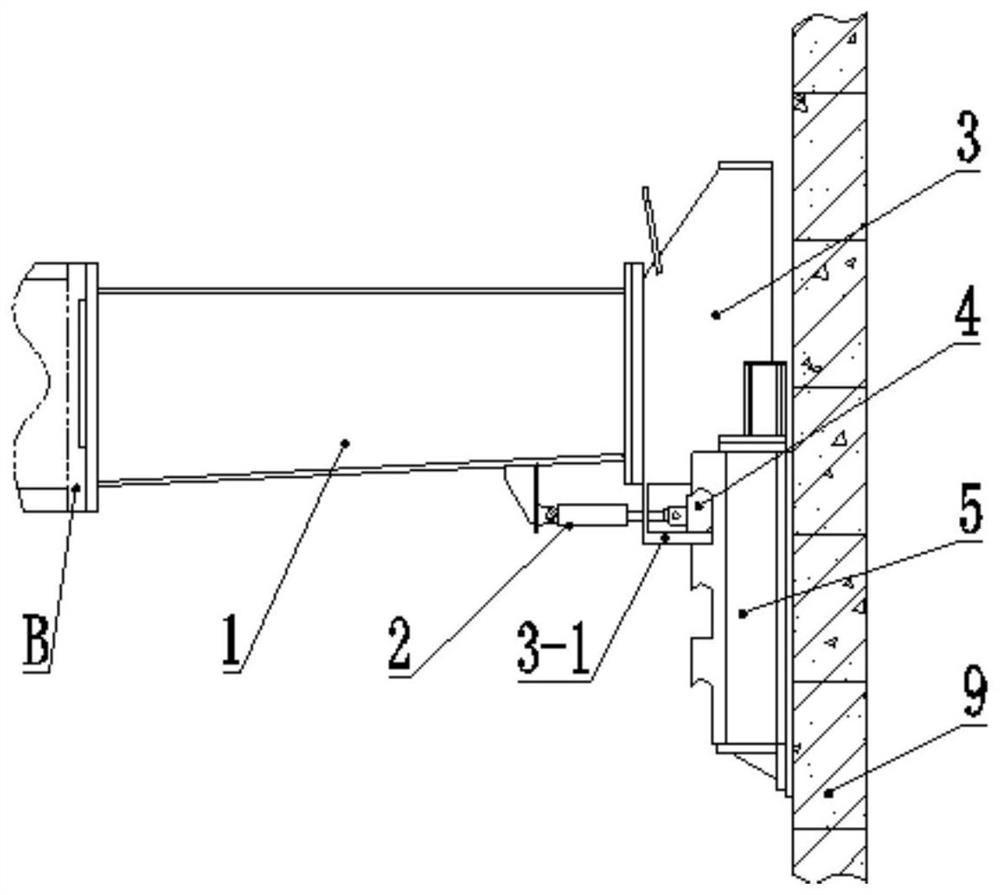

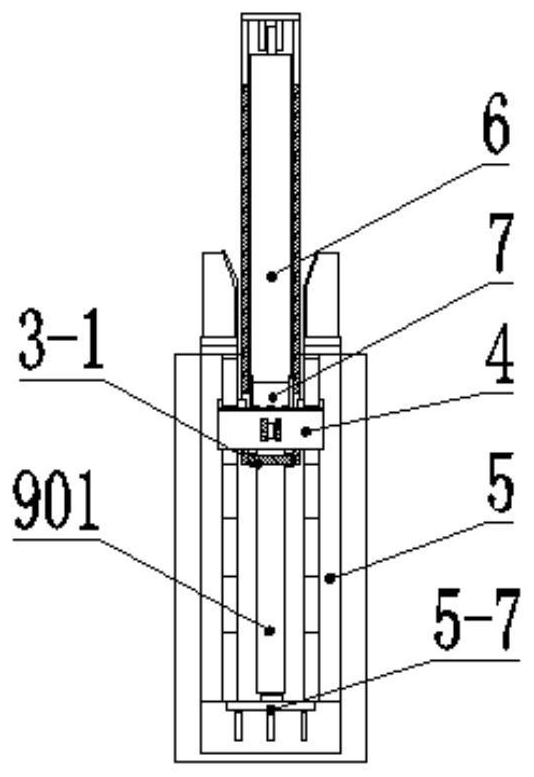

[0036] like Figure 1-6 As shown, the present invention includes a support base 3 arranged at the front end of the support arm 1 of the roadheader and a fixed base 5 for docking the fixed segment 90. The fixed base 5 can reciprocate up and down along the support base 3; drive mechanism 6;

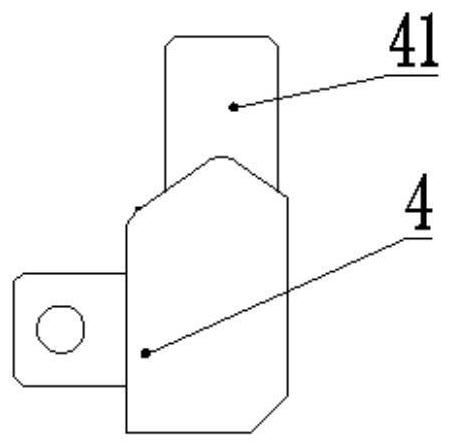

[0037] The support arm 1 of the roadheader is provided with a self-locking wedge block 4; the fixed seat 5 is provided with a number of wedge block semi-closed grooves 50 along the movement direction of the fixed seat 5;

[0038] The semi-closed groove 50 of the wedge block includes a locking catch 5-8 matching the tip of the self-locking wedge 4, a directional conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com