Intelligent laser-guided positioning sampling device for CT (computed tomography) puncture

A laser-guided and sampling device technology, applied in the direction of puncture needles, stereotaxic surgical instruments, surgical robots, etc., to achieve the effect of ensuring hygiene, reducing operating burden, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

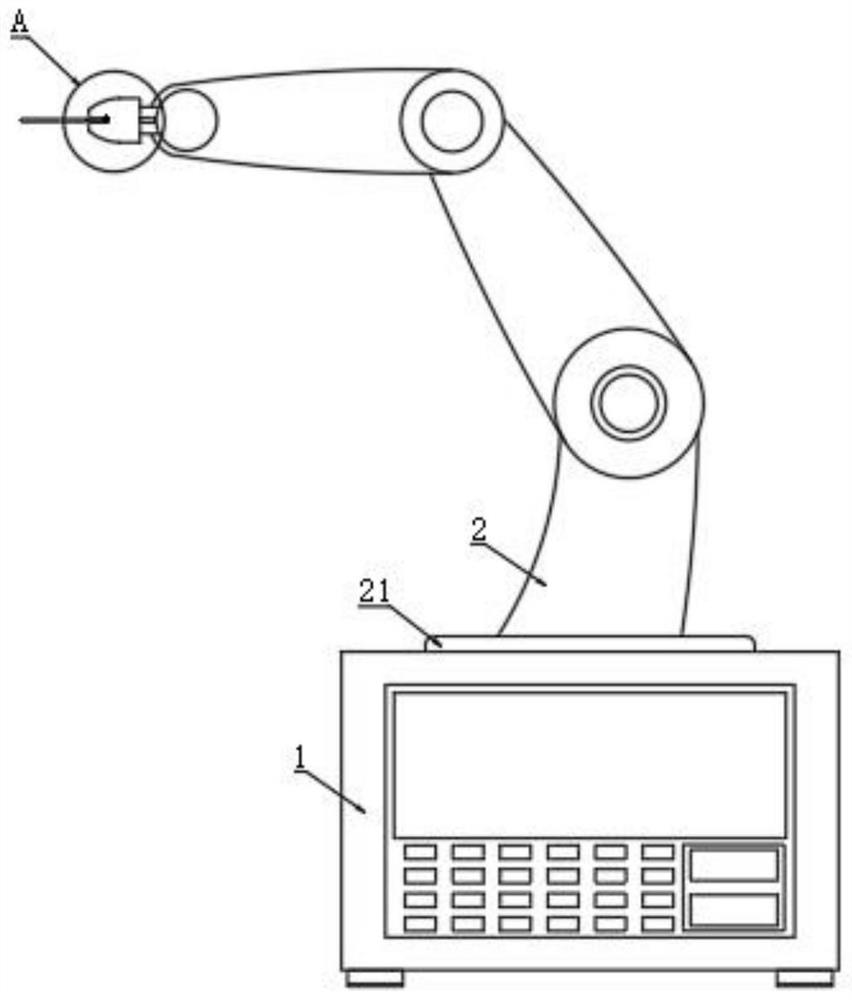

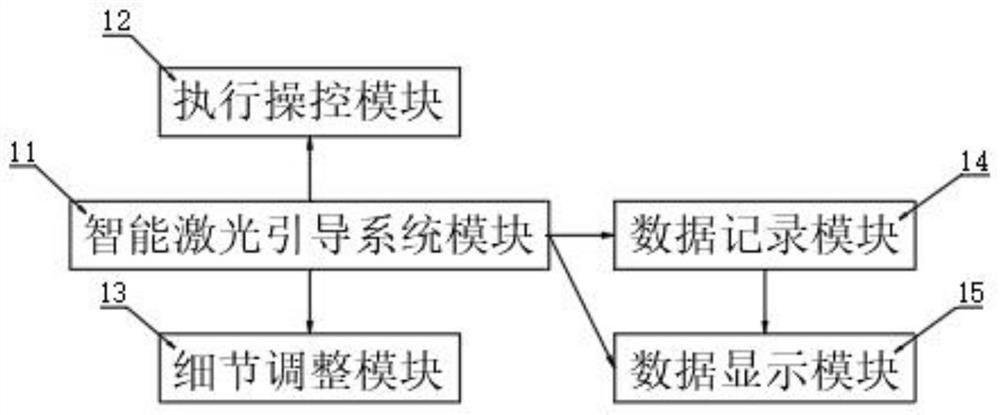

[0032] like Figure 1-Figure 4 As shown, the CT puncture intelligent laser-guided positioning sampling device includes a device body 1, a puncture mechanism and a control mechanism. The puncture mechanism includes a robotic arm 2, and the robotic arm 2 is located on the top surface of the device body 1; One end face of the robotic arm 2; a sliding rail 23, the sliding rail 23 is opened on the outside of the tip turning block 22; the sliding block 24, the sliding block 24 is slidably connected to the inner side of the sliding rail 23; the puncture needle 4, one end of the puncture needle 4 is movably connected to the sliding block 24 On the inner side, the other end of the puncture needle 4 is located outside the sliding block 24; the control mechanism includes the intelligent laser guidance system module 11, the execution control module 12, the detail adjustment module 13, the data recording module 14 and the data display module 15, the intelligent laser guidance system module ...

Embodiment 2

[0038] In other embodiments, this embodiment discloses, please such as figure 1 , Figure 4 , Figure 5 , Image 6 As shown, it also includes a connecting mechanism, the connecting mechanism includes a connecting groove 25, the connecting groove 25 is opened on one side surface of the sliding block 24, one end of the puncture needle 4 is movably connected to the inner side of the connecting groove 25, and the inner side of the connecting groove 25 is fixedly connected to the limiting block 26, A limit slot 41 is provided on the outside of the puncture needle 4, the limit block 26 is movably connected to the inner side of the limit slot 41, and four limit blocks 26 are arranged around the inner side of the connection slot 25. The limit slots 41 and the limit blocks 26 have the same number. And the outer sides of the four limit blocks 26 are all provided with anti-skid patterns.

[0039] Insert the puncture needle 4 into the connecting groove 25 and push it hard so that the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com