Metal bipolar plate gas expansion forming device and process based on pulse current assistance

A metal bipolar plate, pulse current technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inconcentrated heating area, inability to heat the sheet material, large heat loss, etc., to achieve low cost and improve production. Efficiency, rapid heating and thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

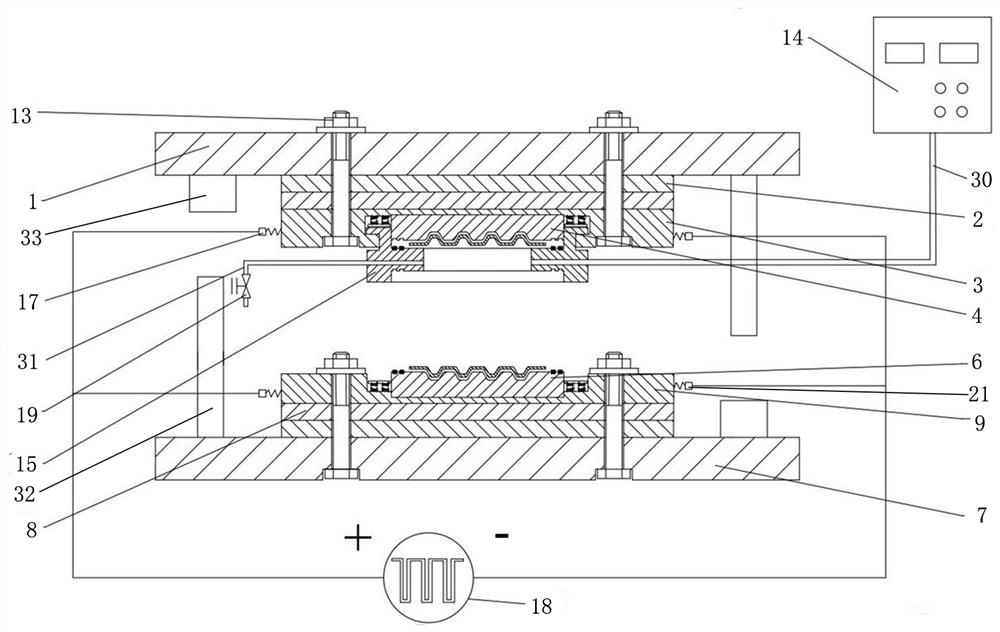

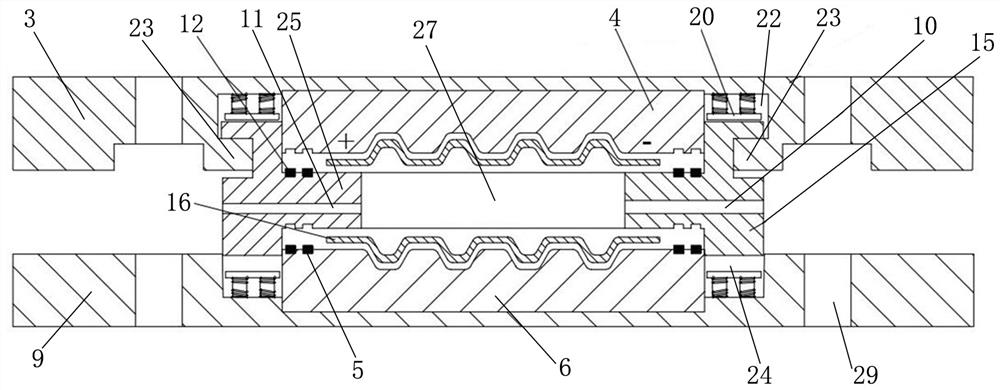

[0033] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0034] A metal bipolar plate inflatable forming device based on pulse current assistance, such as figure 1As shown, an upper module 1 and a lower module 7 are included. The upper die fixing base 3 is installed on the lower surface of the upper die set 1 through insulating bolts 13, and the upper die fixing base 3 and the lower surface of the upper die set 1 are separated by an upper insulating pad 2; that is, the upper die fixing base 3, the upper die The group 1 and the upper insulating backing plate 2 are correspondingly provided with bolt through holes 29 , which are connected and fixed by the insulating bolts 13 . In the same way, the lower die fixing base 9 is installed on the upper surface of the lower die set 7 through insulating bolts 13, and the lower die fixing base 9 and the upper surface of the lower die set 7 are separated by s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com